Bi-S binary system pyroelectric material and production method

A binary system and technology of thermoelectric materials, applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., to achieve the effect of simple process, low sintering temperature, and short synthesis and molding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

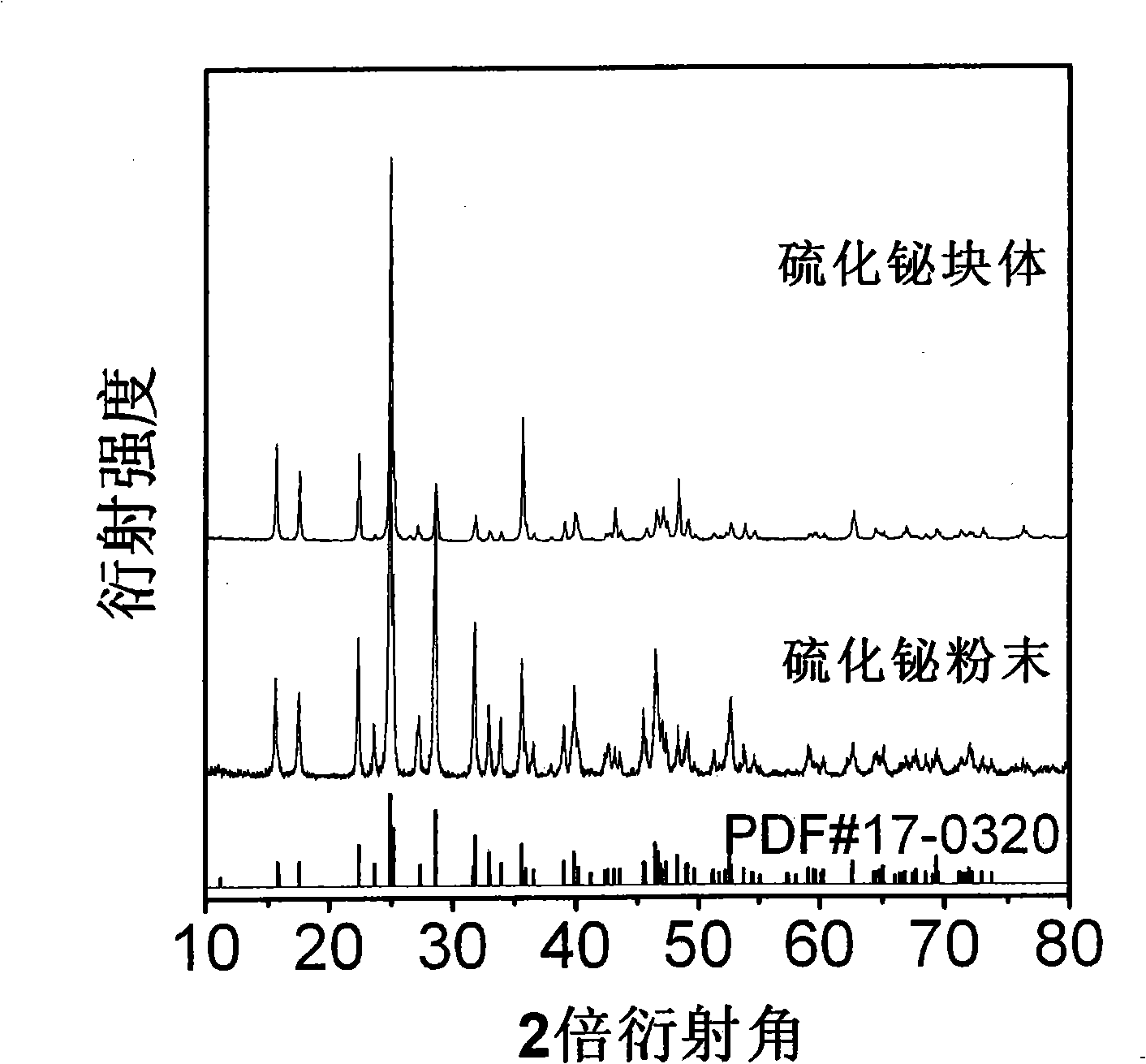

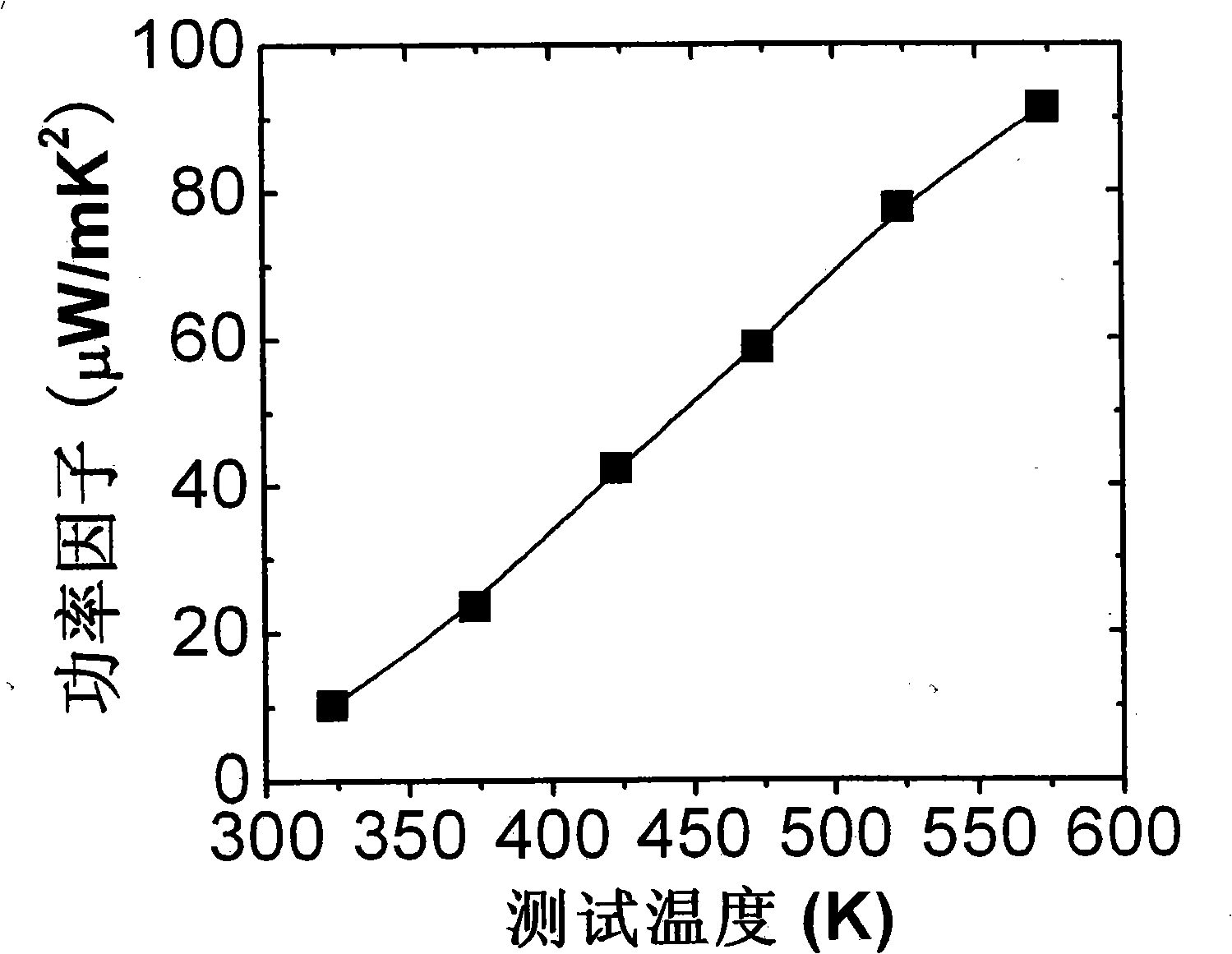

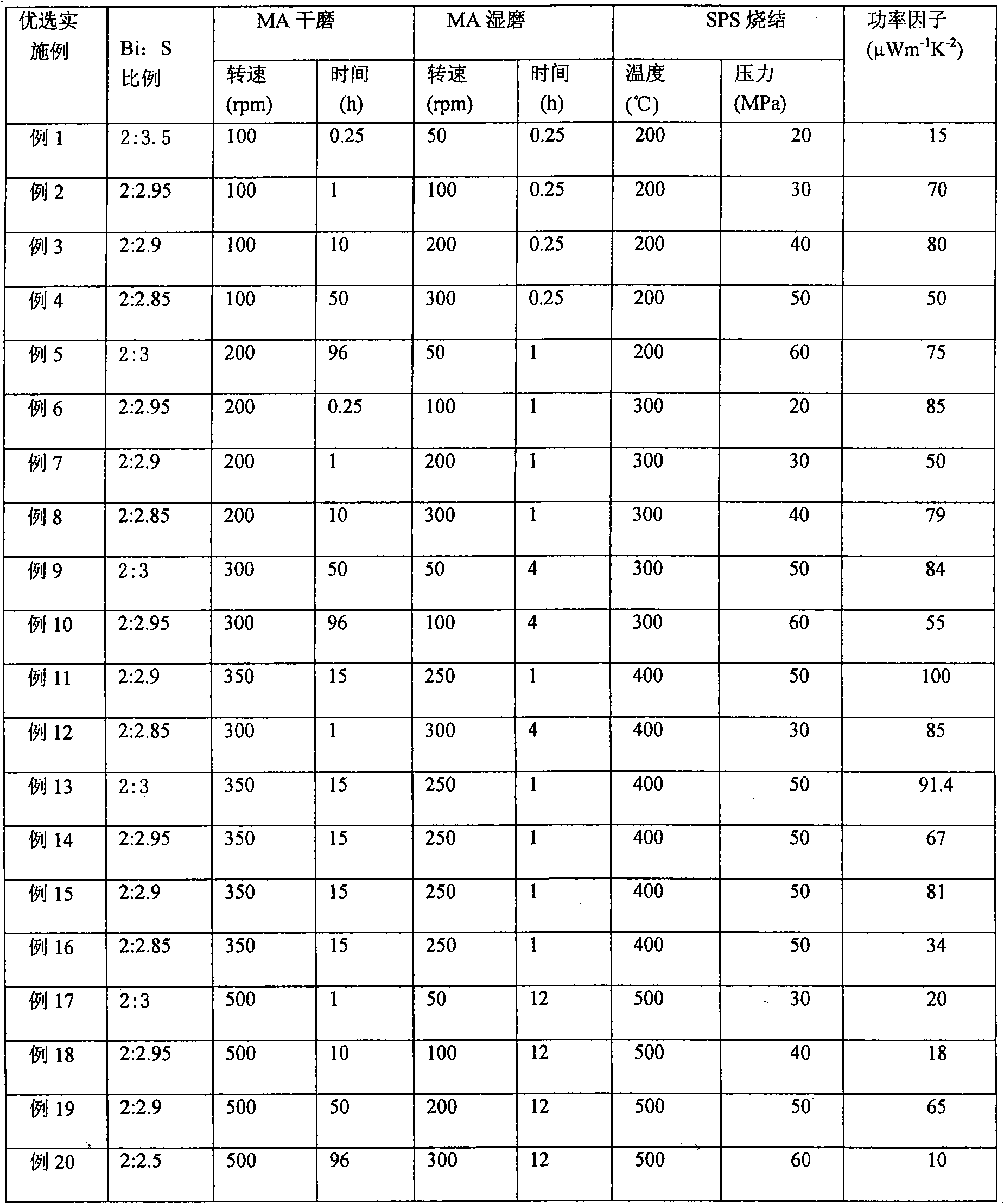

[0018] First, the mechanical alloying method (MA) was used to prepare Bi-S binary compound precursor fine powder. The method is to mix the high-purity Bi and S elemental powders according to the atomic ratio of 2:x (x=2.5-3.5), put them together into a planetary high-energy ball mill for mechanical alloying under the protection of an inert gas, and dry-mill to synthesize the compound. Then carry out wet grinding, and finally dry to obtain the fine powder of Bi-S binary compound, and then sinter the powder into a block by using discharge plasma technology. The sintering temperature is 200-500° C., the holding time is 2-8 minutes, and the pressure is 20-60 MPa.

[0019] Table 1 has provided several preferred embodiments of the present invention:

[0020]

[0021] In summary, the present invention can quickly and easily prepare a thermoelectric bulk material of Bi-S binary system through mechanical alloying and discharge plasma technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com