Composite constructed wetland system and pretreatment method for drinking water source

A constructed wetland system and constructed wetland technology, applied in the field of drinking water source composite constructed wetland system and pretreatment, can solve the problems of high cost of advanced water treatment, difficulty of advanced treatment, low removal efficiency, etc., to improve nitrification capacity, run Long time, the effect of improving the removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

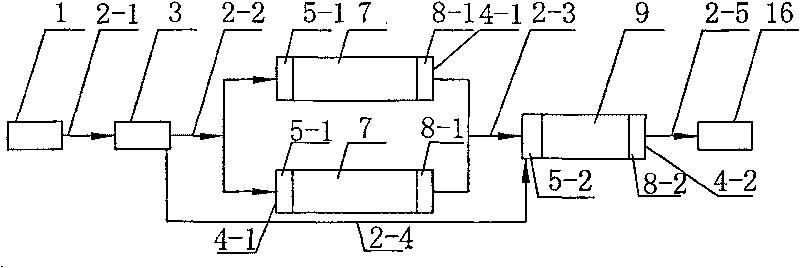

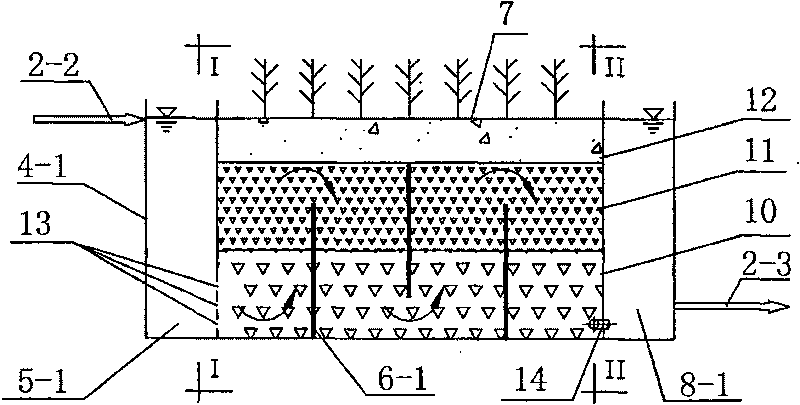

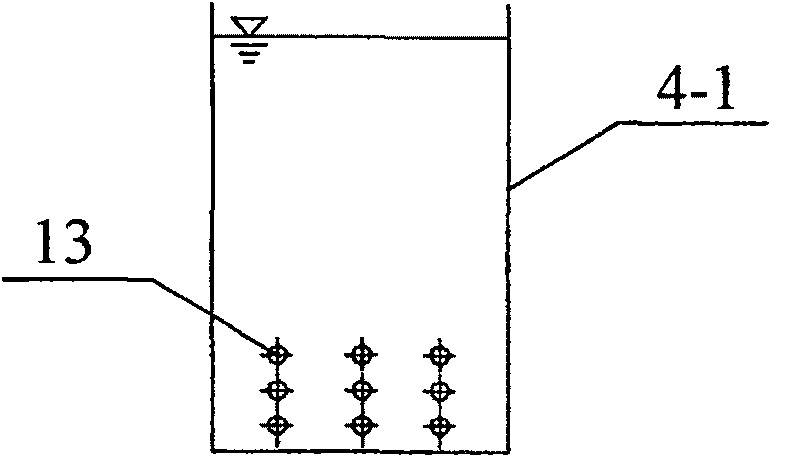

[0012] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 5 , Figure 6 The present embodiment will be described. In this embodiment, the raw water 1, the first water delivery pipeline 2-1, the second water delivery pipeline 2-2, the third water delivery pipeline 2-3, the fourth water delivery pipeline 2-4, and the fifth water delivery pipeline 2- 5. Grit chamber 3, two first pool bodies 4-1, second pool body 4-2, first water inlet sump 5-1, second water inlet sump 5-2, first deflector 6-1, the second deflector 6-2, two up and down baffled submerged flow artificial wetlands 7, the first water outlet pool 8-1, the second water outlet pool 8-2, the surface flow waveform artificial wetland 9 and the perforated pool The water pipe 14 is composed of a first water inlet sump 5-1 in the left end of the first pool body 4-1, and a first water outlet sump 8-1 in the right end of the first pool body 4-1. Between the first water inlet pool 5-1 and th...

specific Embodiment approach 2

[0014] Specific implementation mode 2: The length-to-width ratio of the upper and lower baffled subsurface constructed wetland pools in this embodiment is 4:1, the bottom slope is controlled within 1-4%, and the water depth is 0.6-0.7m.

specific Embodiment approach 3

[0015]Specific embodiment three: the diameter of the large gravel in this embodiment and the ceramsite mixed layer is 50-60 mm, the diameter of the ceramsite is 4-5 mm, and the diameter of the small gravel in the ceramsite mixed layer is 20-30 mm. The diameter of ceramsite is 3-3.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com