Cement clinker and preparation thereof

A cement clinker and raw material technology, applied in the direction of cement production, etc., can solve the problems of clinker quality decline, difficult to burn, f-CaO content increase, etc., to achieve improved utilization rate, stable quality, and easy realization of grinding and calcination processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

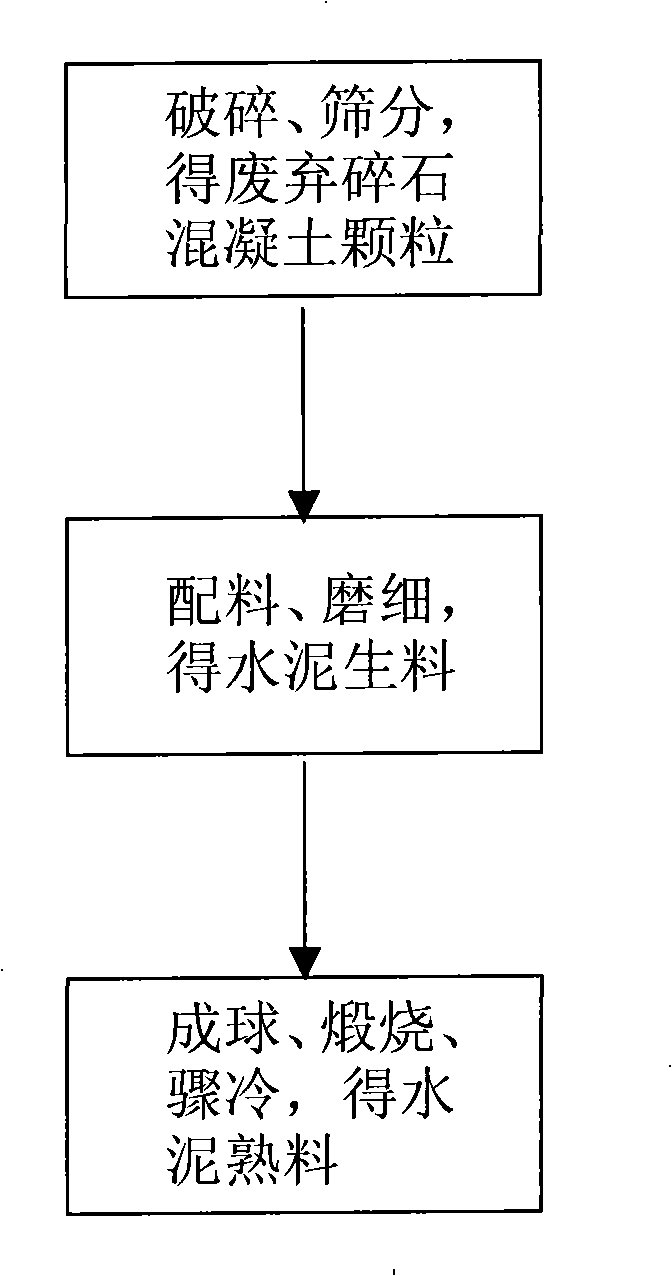

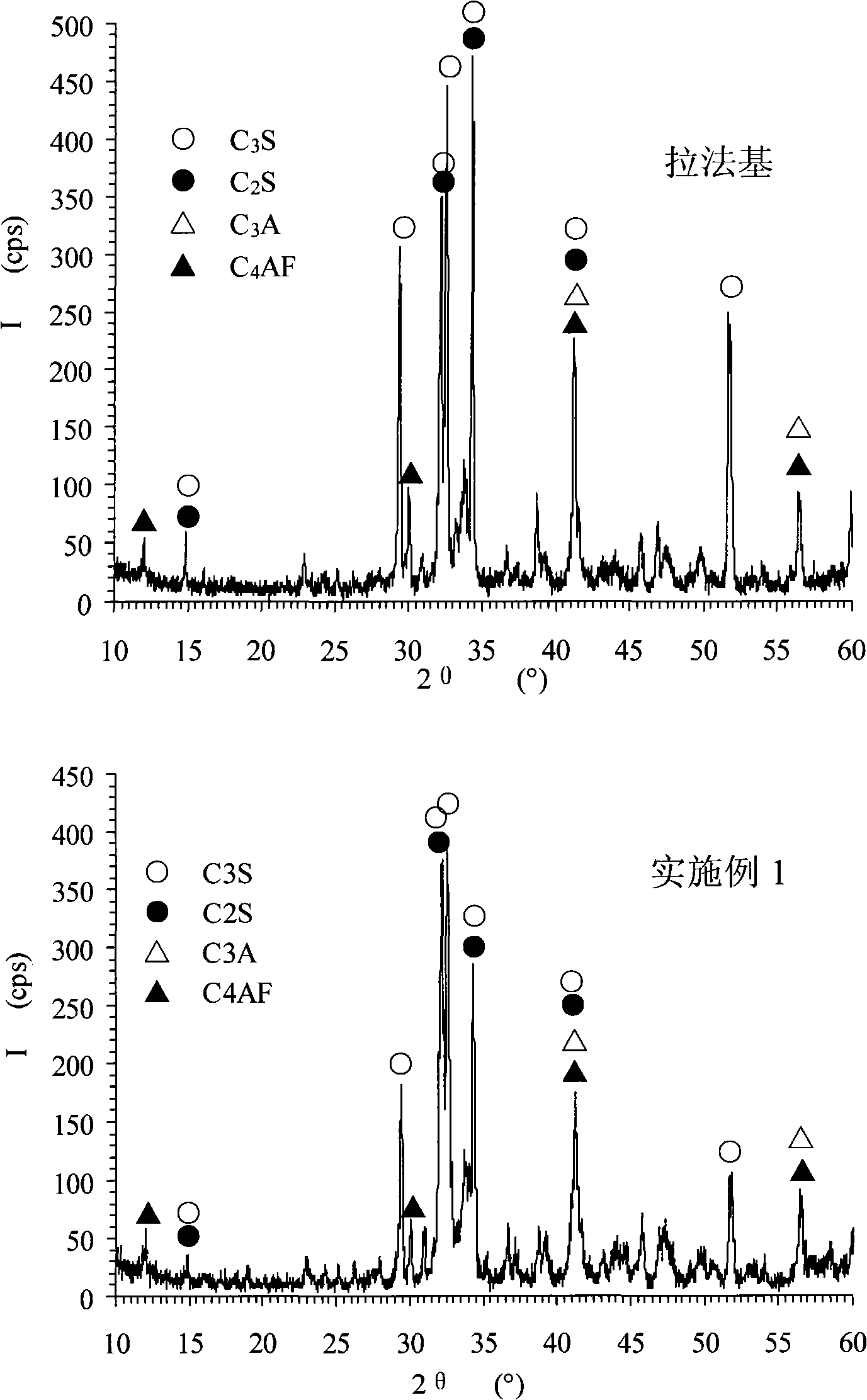

Embodiment 1

[0025] Example 1: The waste concrete is taken from some demolished buildings or structures in the urban area of Chongqing. The limestone, sandstone and sulfuric acid slag required for preparing cement raw meal powder are taken from the Lafarge Cement Factory in Chongqing, and from the Lafarge Cement Factory in Chongqing. The cement factory took the cement clinker used to prepare 42.5 ordinary Portland cement, and purchased 32.5 composite Portland cement, 42.5, 52.5 grades and Chongqing Diwei cement produced by Chongqing Lafarge Cement Factory from the market. The 42.5 grade ordinary Portland cement produced by the factory was used as a comparative analysis experiment. The design rate value of cement clinker is the same as the design rate value of cement clinker prepared by Chongqing Lafarge Cement Plant for 42.5 grade ordinary Portland cement, namely: lime saturation coefficient KH=0.93±0.02, aluminum rate IM=1.5± 0.1, silicon rate SM=2.5±0.1, press figure 1 The steps shown...

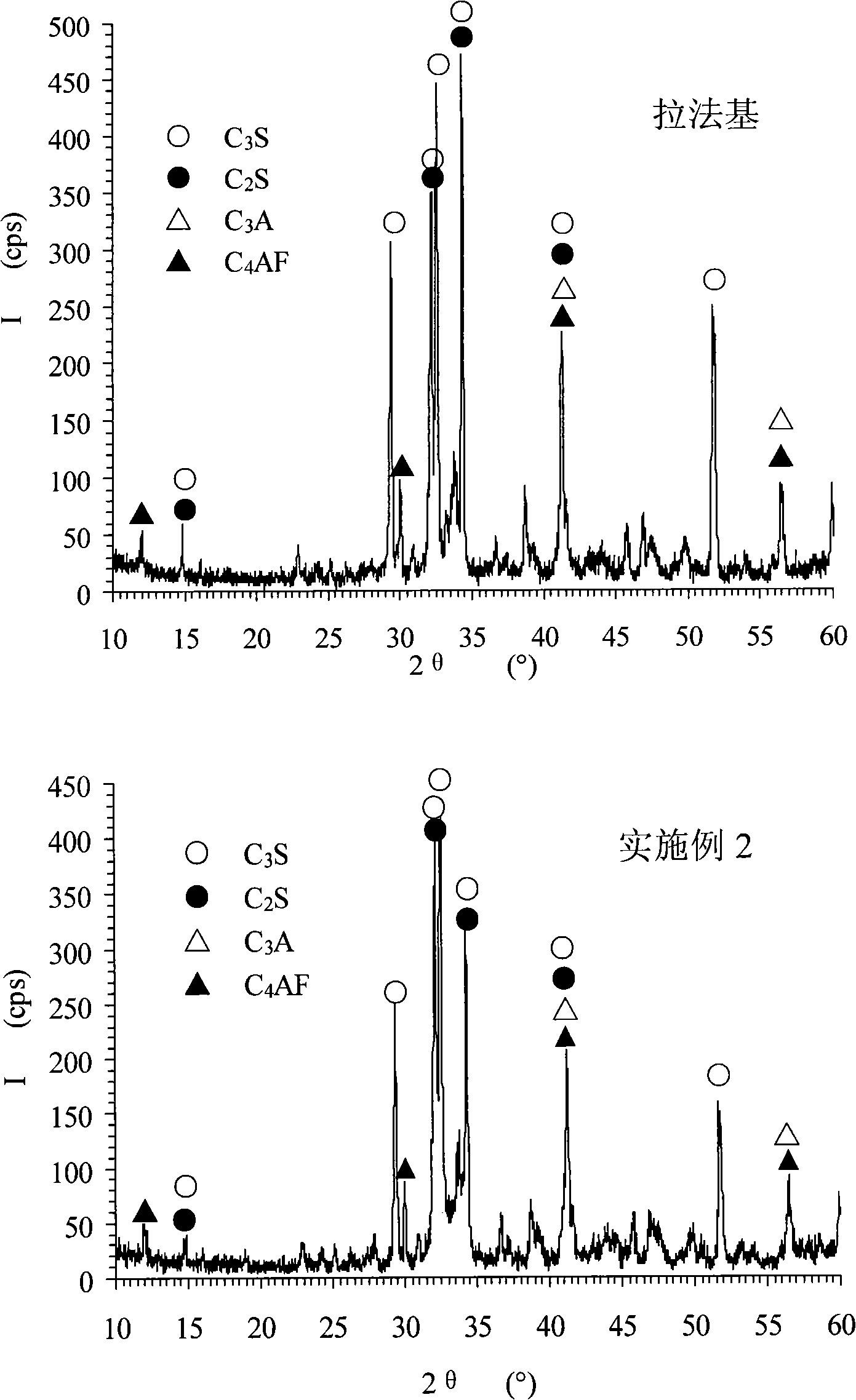

Embodiment 2

[0038] Example 2: The waste concrete is taken from some demolished buildings or structures in the urban area of Chongqing, and the limestone, sandstone and sulfuric acid slag required for preparing cement raw meal powder are taken from the Chongqing Lafarge Cement Plant, and are obtained from the Chongqing Lafarge Cement Factory. The cement factory took the cement clinker used to prepare 42.5 grade ordinary Portland cement, purchased 32.5 composite Portland cement produced by Chongqing Lafarge Cement Factory, 42.5, 52.5 grades and Chongqing Diwei cement from the market The 42.5 grade ordinary Portland cement produced by the factory was used as a comparative analysis experiment. The design rate value of cement clinker is the same as the design rate value of cement clinker prepared by Chongqing Lafarge Cement Plant for 42.5 grade ordinary Portland cement, namely: lime saturation coefficient KH=0.93±0.02, aluminum rate IM=1.5± 0.1, silicon rate SM=2.5±0.1, press figure 1 The s...

Embodiment 3

[0051] Example 3: The waste concrete is taken from some demolished buildings or structures in the urban area of Chongqing. The limestone, sandstone and sulfuric acid slag required for preparing cement raw meal powder are taken from the Chongqing Lafarge Cement Factory, and are obtained from the Chongqing Lafarge Cement Factory. The cement factory took the cement clinker used to prepare 42.5 grade ordinary Portland cement, purchased 32.5 composite Portland cement produced by Chongqing Lafarge Cement Factory, 42.5, 52.5 grades and Chongqing Diwei cement from the market The 42.5 grade ordinary Portland cement produced by the factory was used as a comparative analysis experiment. The design rate value of cement clinker is the same as the design rate value of cement clinker prepared by Chongqing Lafarge Cement Plant for 42.5 grade ordinary Portland cement, namely: lime saturation coefficient KH=0.93±0.02, aluminum rate IM=1.5± 0.1, silicon rate SM=2.5±0.1, press figure 1 The ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com