High precision split joint sub lens relative tilt error photo-electric detection system

A tilt error, photoelectric detection technology, applied in the relative field between spliced sub-mirrors, can solve the problems of insufficient detection accuracy, practicability, and operability, achieve high-quality imaging promotion, improve observation efficiency, and detection accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

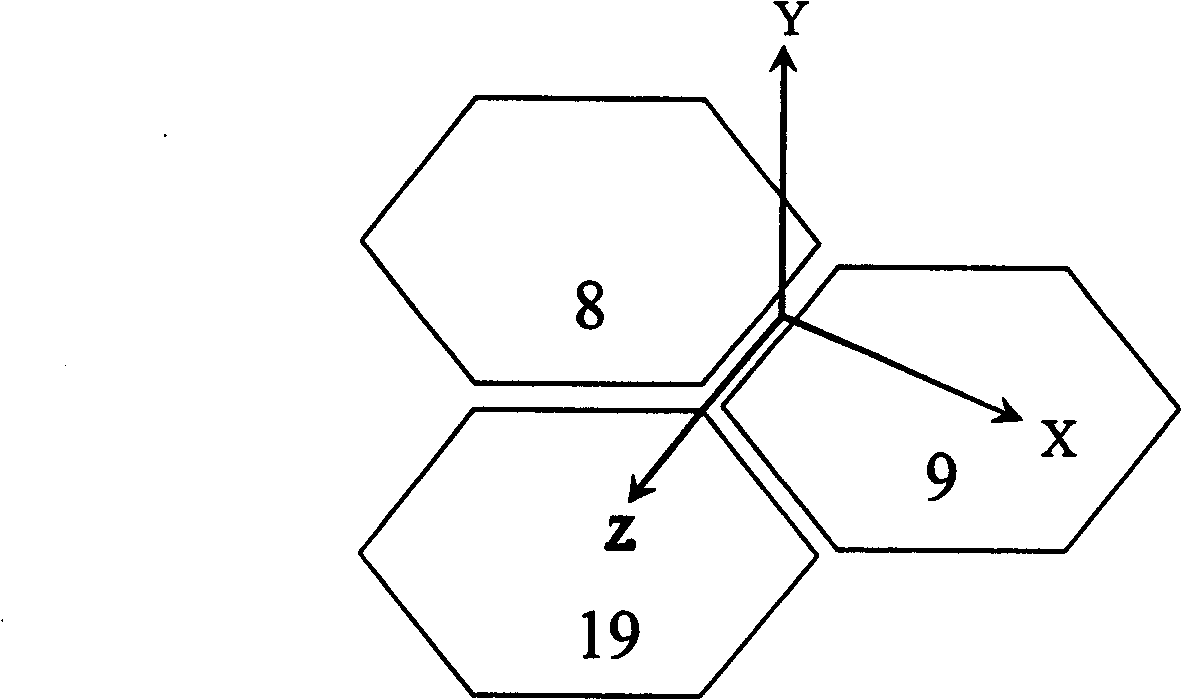

[0017] figure 1 It is an analysis diagram of the degree of freedom of splicing sub-mirrors in a large-aperture telescope in a three-dimensional coordinate system. The relative tilt error between the sub-mirrors around the X-axis is called tilt error, and the relative tilt error between sub-mirrors around the Z-axis is called tip error. figure 1 Shown in is the three sub-mirror splicing main mirror, wherein 8, 9, and 19 represent the first, second and third sub-mirrors respectively.

[0018] Such as figure 2 as shown, figure 2 It is a schematic diagram of the surface shape of a large-aperture telescope when there is a tilt error between the spliced sub-mirrors, in which the six peripheral sub-mirrors represent the situation where the coplanar arrangement has been realized, and the middle sub-mirror is not coplanarly arranged, that is, relative to the surrounding six sub-mirrors The situation when there is a tilt error in the sub-mirror.

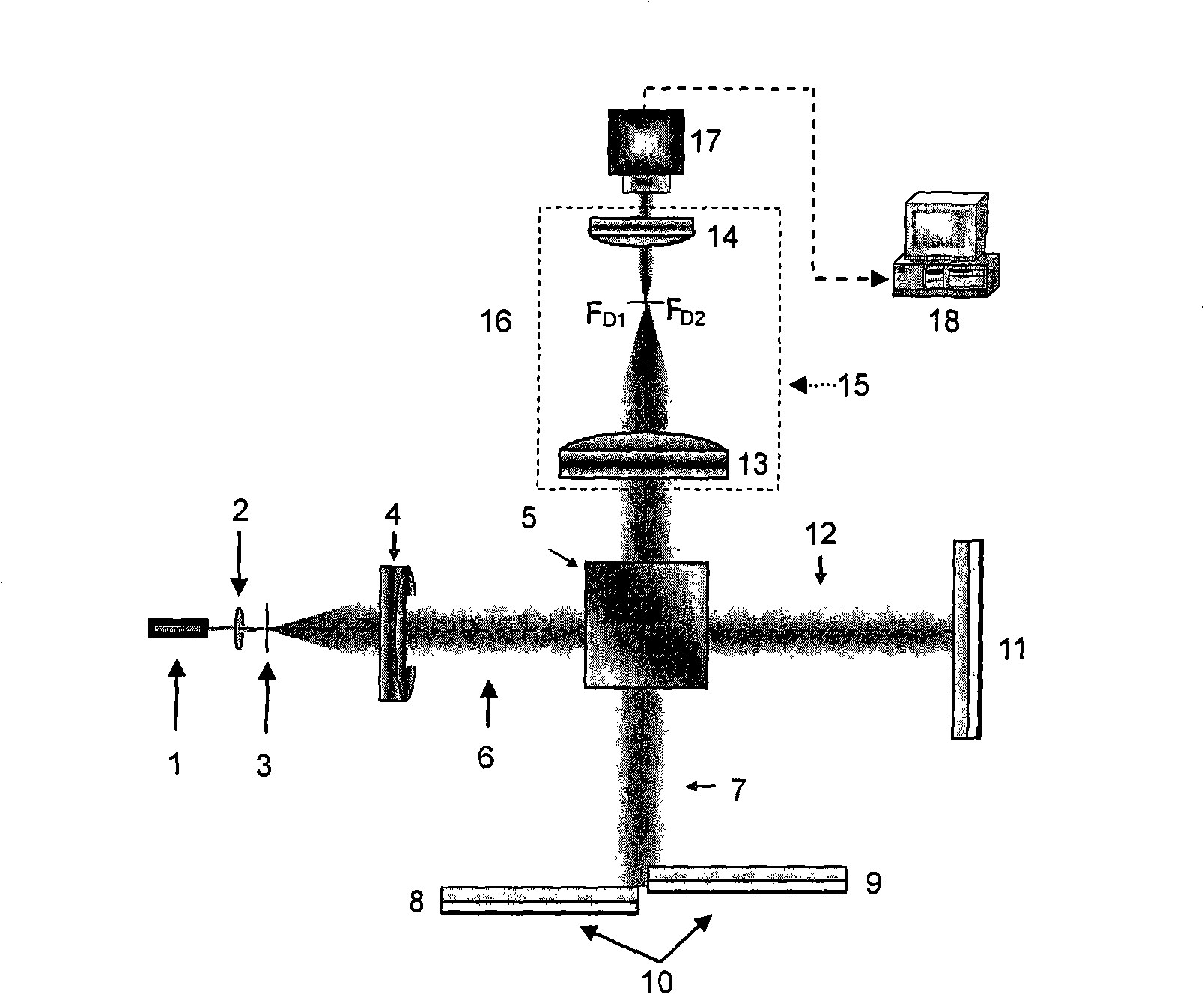

[0019] Such as image 3 As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com