Preparation of fusiform anatase TiO2 nanocrystalline material

A nanocrystalline material and anatase technology, applied in the nanomaterials and nano fields, can solve the problem of few researches on special-shaped nanocrystalline materials, and achieve the effects of low cost, high controllability and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A spindle-shaped anatase TiO 2 The preparation method of nanocrystalline material, it comprises the steps:

[0023] 1) 3.33g of commercial TiO 2 The powder was placed in a sodium hydroxide solution with a volume of 100ml and a molar concentration of 10M and vigorously stirred for 36h to obtain a suspension solution A;

[0024] 2) The suspension solution A is hydrothermally reacted at a temperature of 180° C. for 48 hours by a hydrothermal method;

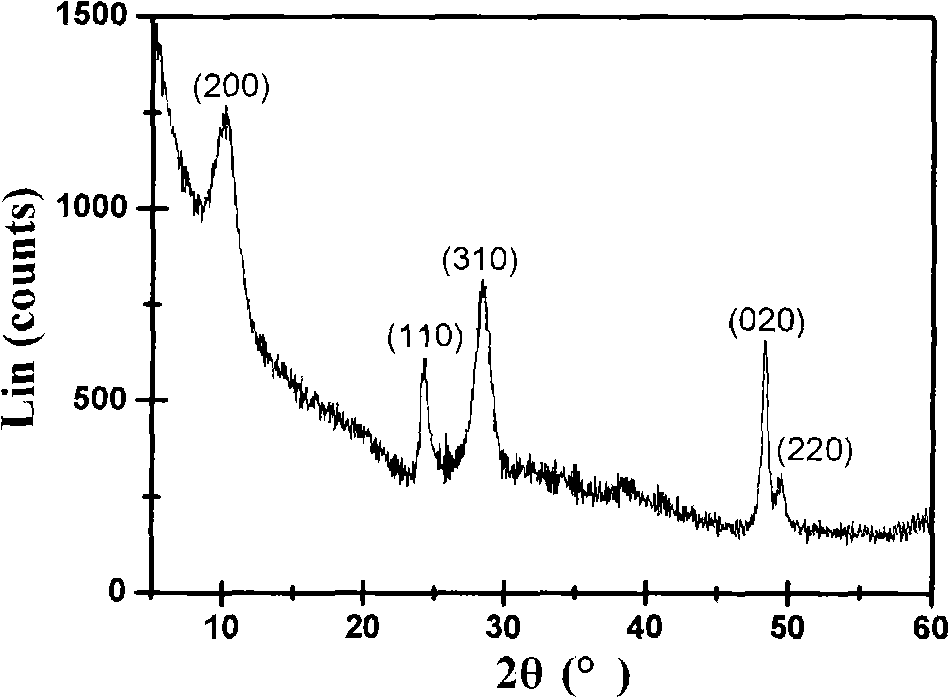

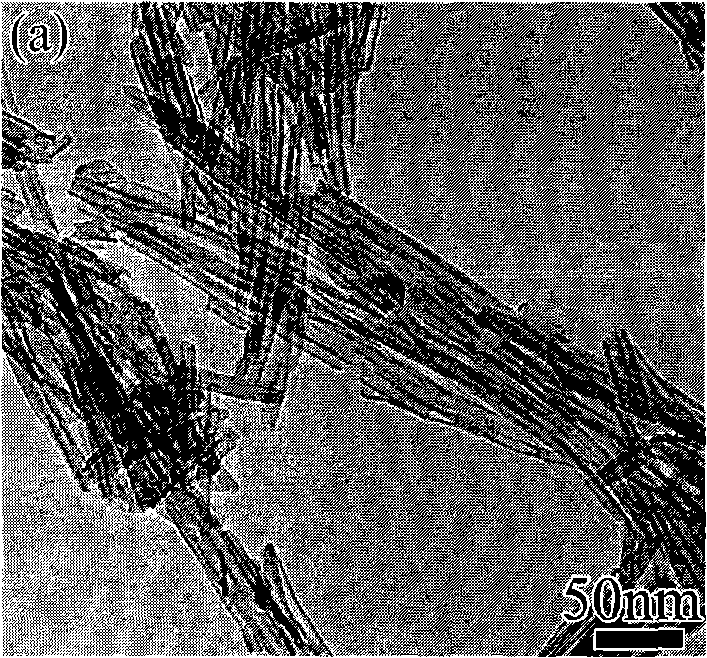

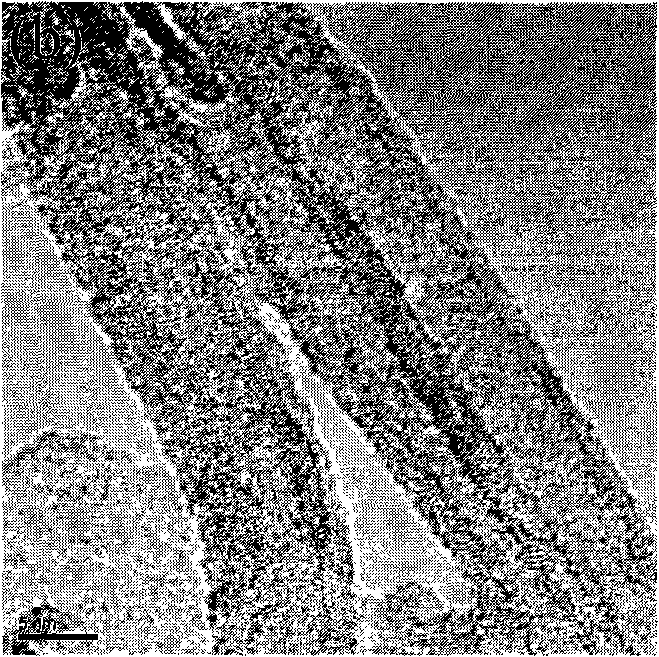

[0025] 3) Then dropwise add HCl solution with a concentration of 0.1M to adjust the pH value to 7.0, filter and dry at 80°C for 24 hours to obtain 3.91g of one-dimensional titanic acid (H 2 Ti 5 o 11 ·3H 2 O) nanotube material; {gained one-dimensional titanic acid (H 2 Ti 5 o 11 ·3H 2 O) The XRD pattern of the nanotube material is shown in figure 1 ; TEM photo, HRTEM photo of microstructure characterization, see Figure 2a , Figure 2b}

[0026] 4) 3.91g of the one-dimensional titanate nanotube material generated...

Embodiment 2

[0034] A spindle-shaped anatase TiO 2 The preparation method of nanocrystalline material, it comprises the steps:

[0035] 1) 3.33g of commercial TiO 2 The powder was placed in a sodium hydroxide solution with a volume of 100ml and a molar concentration of 2.01M and vigorously stirred for 30h to obtain a suspension solution A;

[0036] 2) The suspension solution A is hydrothermally reacted at a temperature of 160° C. for 48 hours by a hydrothermal method;

[0037] 3) Then dropwise add HCl solution with a concentration of 0.1M to adjust the pH value to 7.0, filter and dry at 80°C for 12 hours to obtain 3.91g of one-dimensional titanic acid (H 2 Ti 5 o 11 ·3H 2 O) nanotube material;

[0038] 4) 3.91g of the one-dimensional titanate nanotube material generated by the above reaction and distilled water were prepared into 100ml suspension solution B;

[0039] 5) The suspension solution B was hydrothermally reacted at a temperature of 160° C. for 48 hours by a hydrothermal me...

Embodiment 3

[0042] A spindle-shaped anatase TiO 2 The preparation method of nanocrystalline material, it comprises the steps:

[0043] 1) 3.33g of commercial TiO 2 The powder was placed in a sodium hydroxide solution with a volume of 100ml and a molar concentration of 19.09M and vigorously stirred for 50h to obtain a suspension solution A;

[0044] 2) The suspension solution A was hydrothermally reacted at a temperature of 220° C. for 7 days by a hydrothermal method;

[0045] 3) Then dropwise add HCl solution with a concentration of 0.1M to adjust the pH value to 7.0, filter and dry at 80°C for 24 hours to obtain 3.91g of one-dimensional titanic acid (H 2 Ti 5 o 11 ·3H 2 O) nanotube material;

[0046] 4) 3.91g of the one-dimensional titanate nanotube material generated by the above reaction and 100ml of distilled water were prepared into suspension solution B;

[0047] 5) The suspension solution B was hydrothermally reacted at a temperature of 220° C. for 7 days by a hydrothermal m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outside diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com