Strengthen material for concrete antiabrasion layer of ocean engineering and production method thereof

A technology for strengthening materials and marine engineering, applied in the field of building materials, can solve problems such as seldom considering high-performance cement-based materials marine engineering concrete protective layer, etc., and achieve the effect of improving ion transmission performance and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Production of reinforced material for concrete protective layer in marine engineering

[0024] First add 1800kg of slag powder, 1420kg of fly ash, 5600kg of P·II52.5 cement, 7kg of triethanolamine, 71kg of sodium sulfate, and 69kg of naphthalene sulfonate into the mill for 15 minutes. The speed of the mill is 18 rpm. Then add 980kg of silicon powder, 117.6kg of cement-based permeable crystalline waterproof material (THINKABLE waterproof material produced by Shanghai Shink Waterproof Material Co., Ltd.), and continue to mix and grind for 8 minutes, and then evenly add 9.1kg of polypropylene fiber with a length of 3mm and 10mm. Continue to mix and grind for 8 minutes, until the Blaine's specific surface area of the mixed abrasive is ≥650m 2 / kg, finally add 11760kg of extra-fine sand and continue to mix and grind for 8 minutes. After discharging, 21.5t of reinforcement material for the concrete protective layer of ocean engineering was obtained. The performance te...

Embodiment 2

[0027] Example 2 Engineering application of reinforced material for concrete protective layer in marine engineering

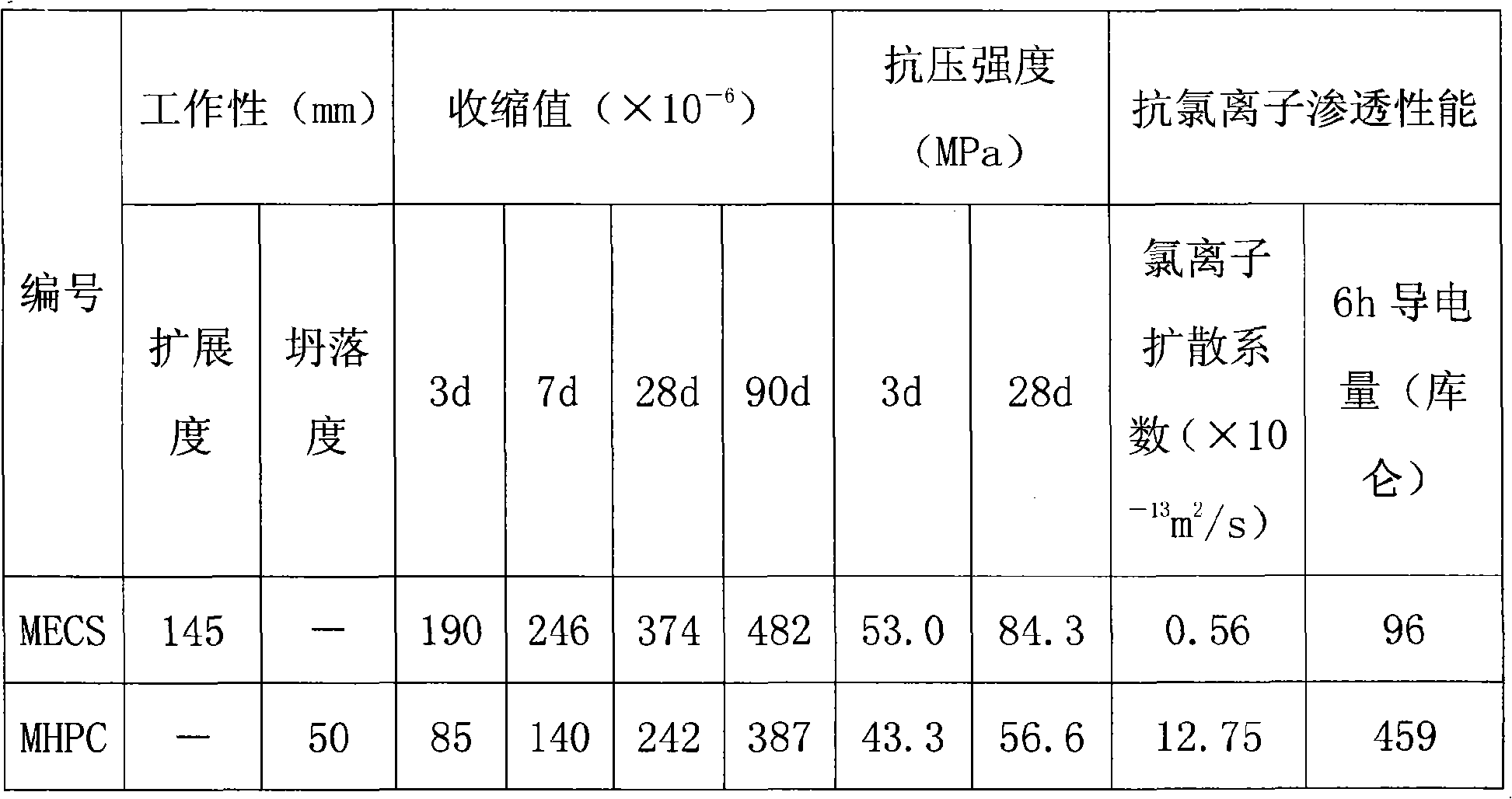

[0028] The reinforced material for the marine engineering concrete protective layer produced in Example 1 was used for the precast pouring of the marine engineering concrete protective layer. In order to illustrate the various properties of the reinforced material for the concrete protective layer of marine engineering, a set of C50 marine high-performance concrete was designed as a comparative sample in the embodiment. The mix ratio of the produced marine engineering concrete protective layer reinforcement material (No.: MECS) and C50 offshore high performance concrete (No.: MHPC) is shown in Table 2, and the performance test data is shown in Table 3.

[0029] Table 2

[0030]

serial number

Reinforced material

Feed

Slag Micro

Pink

Stone

Shrink

Agent

High efficie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chloride diffusion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com