Process for production of thermoplastic resin microporous membranes

一种热塑性树脂、制造方法的技术,应用在化学仪器和方法、膜、膜技术等方向,能够解决色泽不均、混炼故障、微孔膜外观问题等问题,达到降低制造成本、减轻负担、减少废弃物的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] (1) Preparation process of starting material solution

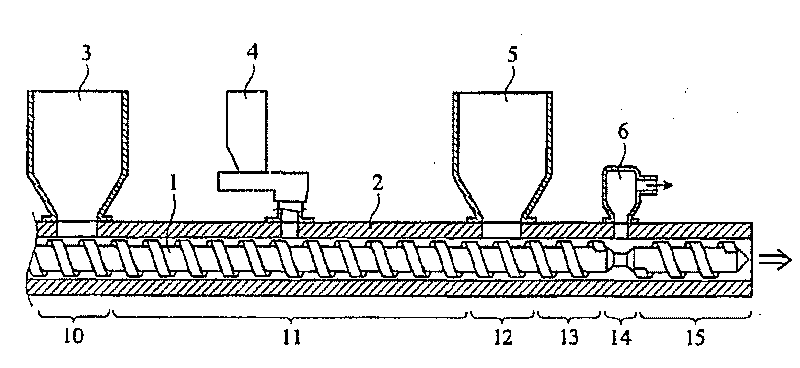

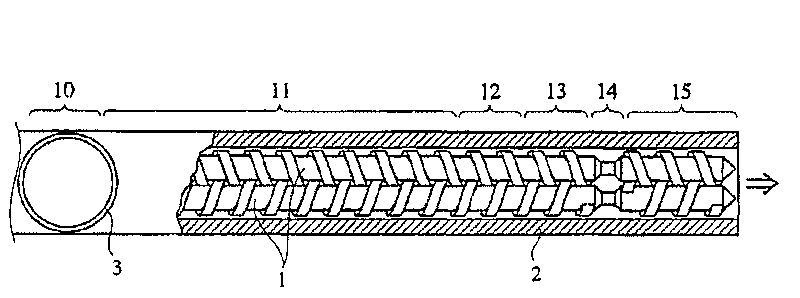

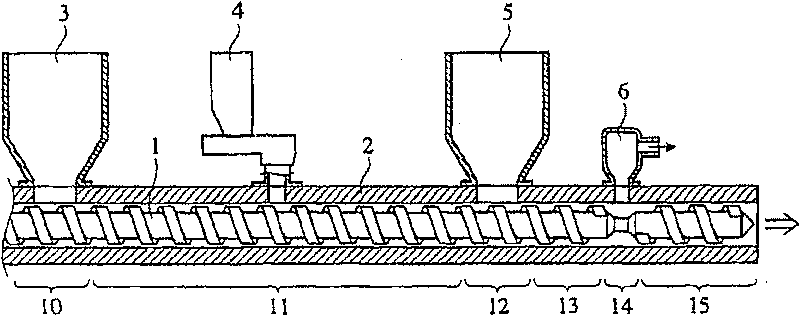

[0030] figure 1 (a) and figure 1 (b) shows an example of the twin-screw extruder used by the 1st manufacturing method. This twin-screw extruder is equipped with screws 1, 1, a cylinder 2 for accommodating them, a first sampling hopper 3 for injecting thermoplastic resin, a side feeder 4 for supplying a solvent for film formation, and a second sampling hopper for injecting broken films. 5 and vent 6.

[0031] Put the above-mentioned thermoplastic resin into the first sampling hopper 3 . The thermoplastic resin can be used either in granular form or in powder form. Depending on the shape of the thermoplastic resin, a well-known quantitative supply device for granules or powder is installed on the upper or lower part of the first sample adding hopper 3, and the thermoplastic resin is injected quantitatively. The film-forming solvent can also be injected into the first sample feeding hopper 3 together with the the...

Embodiment 1

[0078] Polyethylene microporous membranes are produced while recycling the broken membranes (ear ends of gel-like sheets) produced in the same manufacturing process.

[0079] (1) Preparation of starting material solution

[0080] The mass average molecular weight (Mw) of 20% by mass is 2.0×10 6 , Mw / Mn is 8 ultra-high molecular weight polyethylene (UHMWPE) and 80% by mass of Mw is 3.5×10 5 , Mw / Mn is 100 parts by mass of polyethylene (PE) composition composed of high density polyethylene (HDPE) of 13.5 dry mixed tetrakis [methylene-3-(3,5-di-tert-butyl-4- 0.2 parts by mass of hydroxyphenyl) propionate] methane. The melting point of the PE composition composed of UHMWPE and HDPE was measured to be 135°C, and the crystallization dispersion temperature was 100°C.

[0081] Mw and Mw / Mn of UHMWPE and HDPE were determined by gel permeation chromatography (GPC) under the following conditions.

[0082] ・Measuring device: GPC-150C manufactured by Waters Corporation

[0083] ・Colum...

Embodiment 2

[0097] The broken membrane (the ear tip of the gel-like three-layer sheet) produced in the same manufacturing process was reused to produce a polyethylene three-layer microporous membrane at the same time.

[0098] (1) Preparation of starting material solution A

[0099] In the same manner as in Example 1, starting material solution A was prepared using a twin-screw extruder.

[0100] (2) Reuse the preparation of raw material solution B

[0101] The broken film produced by the trimming of the gel-like three-layer sheet in the later stage is crushed into fluff, fed from the feeding hopper with a kneader of the single-screw extruder, and melted under the conditions of 230°C and 250rpm Mixing, preparation and reuse of raw material solution B.

[0102] (3) Film formation

[0103] The obtained starting raw material solution A and the reused raw material solution B were supplied from each extruder to a three-layer T-die (the supply rate of the solution A: 40 kg / h, the supply rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com