Transmission liquid for independent hydraulically controlled clutch system

A hydraulic clutch and transmission fluid technology, applied in the field of transmission fluid, can solve the problems of high price, low boiling point, non-mixable storage and mixed use of brake fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0006] Embodiment 1: the present invention is in concrete implementation, is by weight percentage: the diethylene glycol raffinate 54.8% of mass concentration 75%, the ethylene glycol raffinate 43% of mass concentration 63%, diethanolamine 0.85% , 0.65% triethanolamine, 0.07% benzotriazole, 0.57% sodium nitrite, and 0.06% silicone oil. 43% of the alcohol residue was added to the reactor and heated to 80°C with stirring, then 0.85% of diethanolamine was added and reacted for 45 minutes, followed by adding 0.65% of triethanolamine, 0.07% of benzotriazole, 0.57% of sodium nitrite, and 0.06% of silicone oil %, after the temperature drops to 20°C, stir for 25 minutes, then let stand for 1 hour, and then filter to obtain that.

Embodiment 2

[0007] Embodiment 2: the present invention is in concrete implementation, is by weight percentage: the diethylene glycol raffinate 56.8% of mass concentration 75%, the ethylene glycol raffinate 41% of mass concentration 63%, diethanolamine 0.96% , 0.64% of triethanolamine, 0.08% of benzotriazole, 0.45% of sodium nitrite, and 0.07% of silicone oil. Add 41% of the alcohol residual liquid to the reaction kettle, stir and heat to 80°C, then add 0.96% diethanolamine and react for 45 minutes, then add 0.64% triethanolamine, 0.08% benzotriazole, 0.45% sodium nitrite, and 0.07% silicone oil %, after the temperature drops to 25°C, stir for 30 minutes, then let it stand for 1 hour, and then filter to obtain.

Embodiment 3

[0008] Embodiment 3: the present invention is in concrete implementation, is by weight percentage: the diethylene glycol raffinate 57.4% of mass concentration 75%, the ethylene glycol raffinate 40% of mass concentration 63%, diethanolamine 0.98% , 0.75% of triethanolamine, 0.09% of benzotriazole, 0.7% of sodium nitrite, and 0.08% of silicone oil. Among them, firstly, 56.8% of diethylene glycol raffinate with a mass concentration of 75%, and ethylene glycol with a mass concentration of 63% Add 41% of the alcohol residual liquid to the reaction kettle, stir and heat to 80°C, then add 0.96% diethanolamine and react for 45 minutes, then add 0.64% triethanolamine, 0.08% benzotriazole, 0.45% sodium nitrite, and 0.07% silicone oil %, after the temperature drops to 30°C, stir for 35 minutes, then let stand for 1 hour, and then filter to obtain.

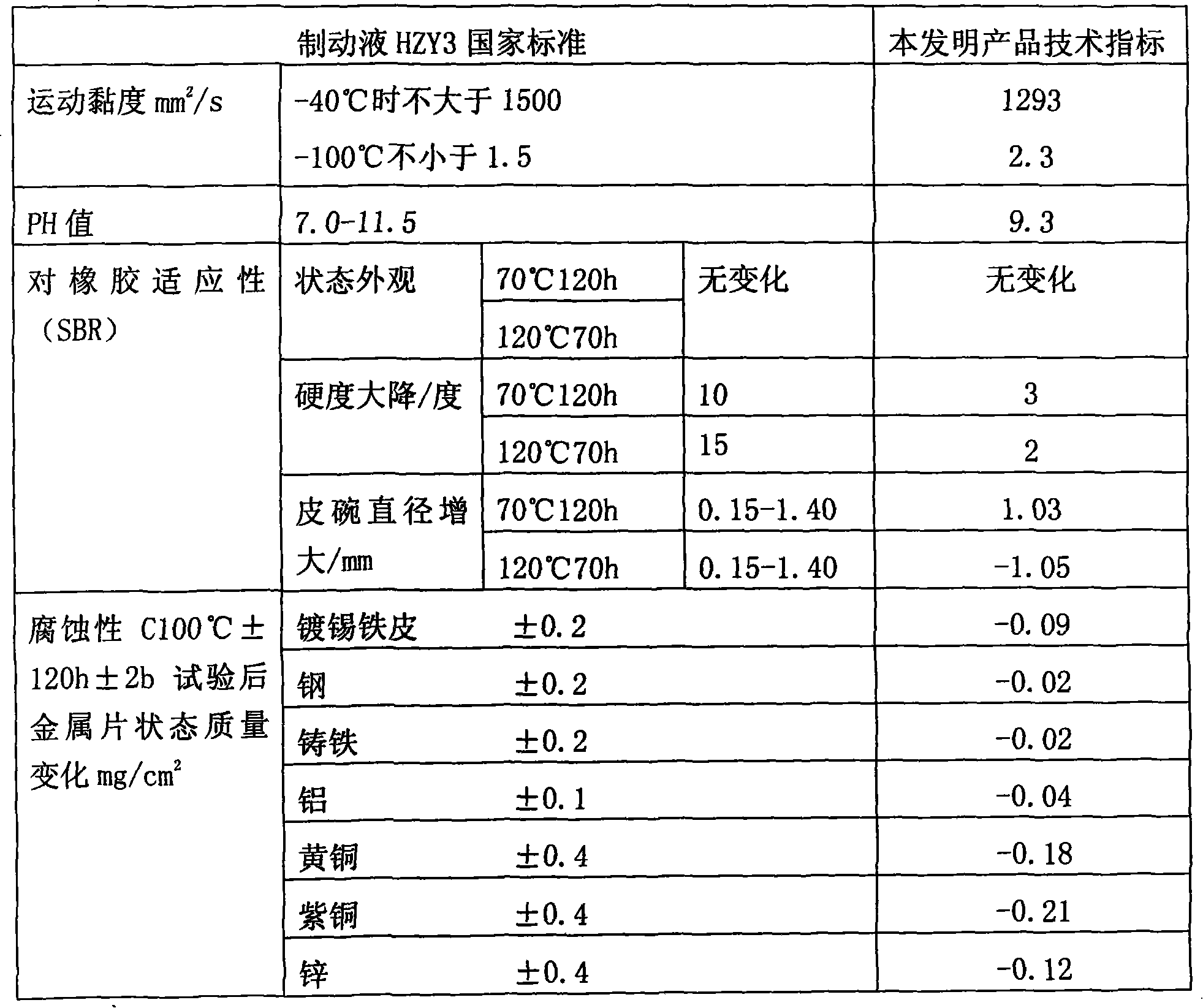

[0009] After testing, the various indicators of the transmission fluid of the present invention all meet the working requirements of the ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com