Semi-penetrating semi-reflective liquid crystal display device and manufacturing method thereof

A semi-transmissive semi-reflective, liquid crystal display panel technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, optics, etc., can solve the complex process, difficulty in subsequent brushing and alignment patterns, and difficulty in arranging spacers for liquid crystal gap height control, etc. problems, to achieve the effect of simplifying the process, increasing the aperture ratio, and increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]In order for those skilled in the art to have a better understanding of the present invention, several preferred embodiments of the present invention are enumerated below, together with the accompanying drawings, to describe in detail the composition and desired effects of the present invention.

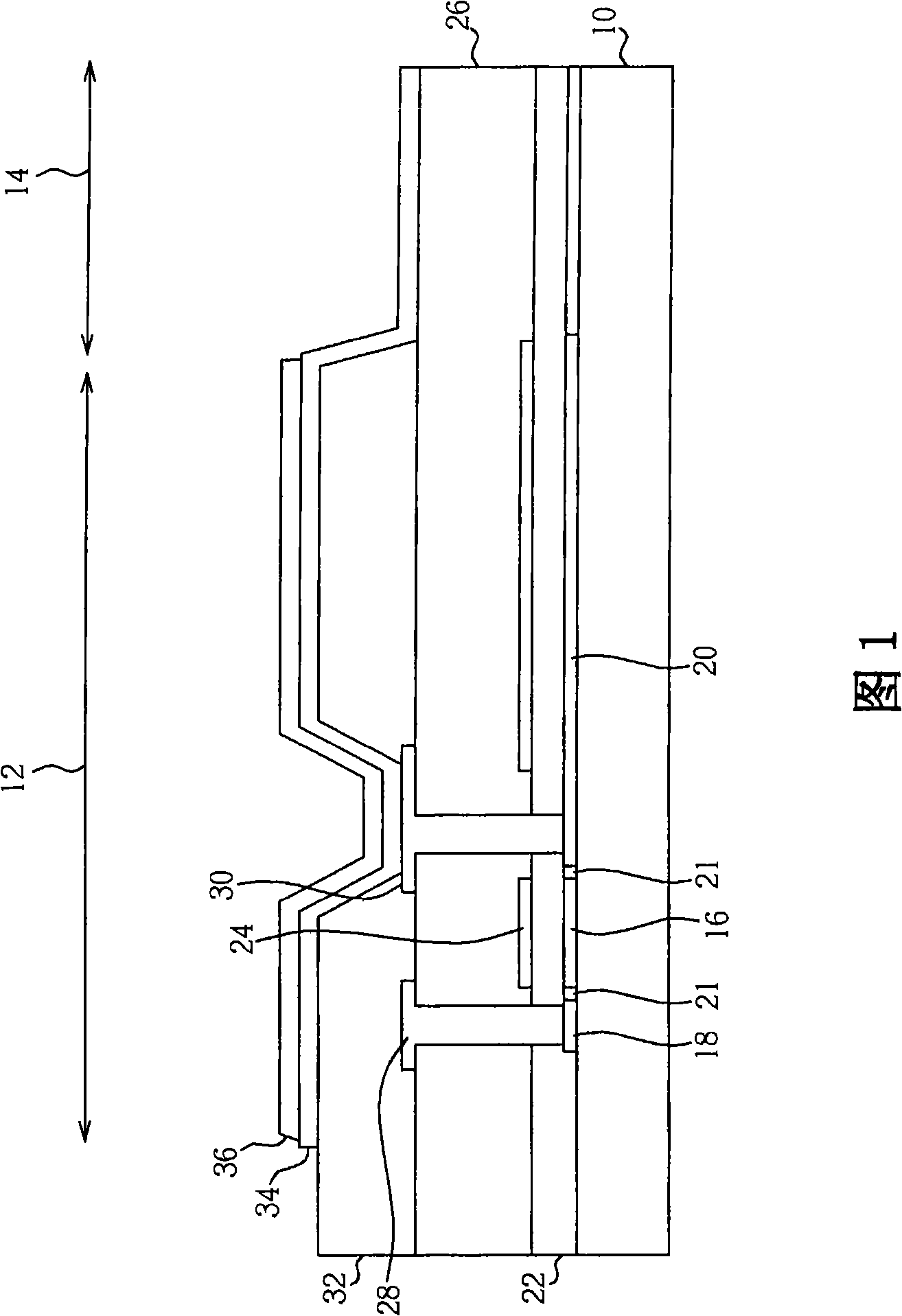

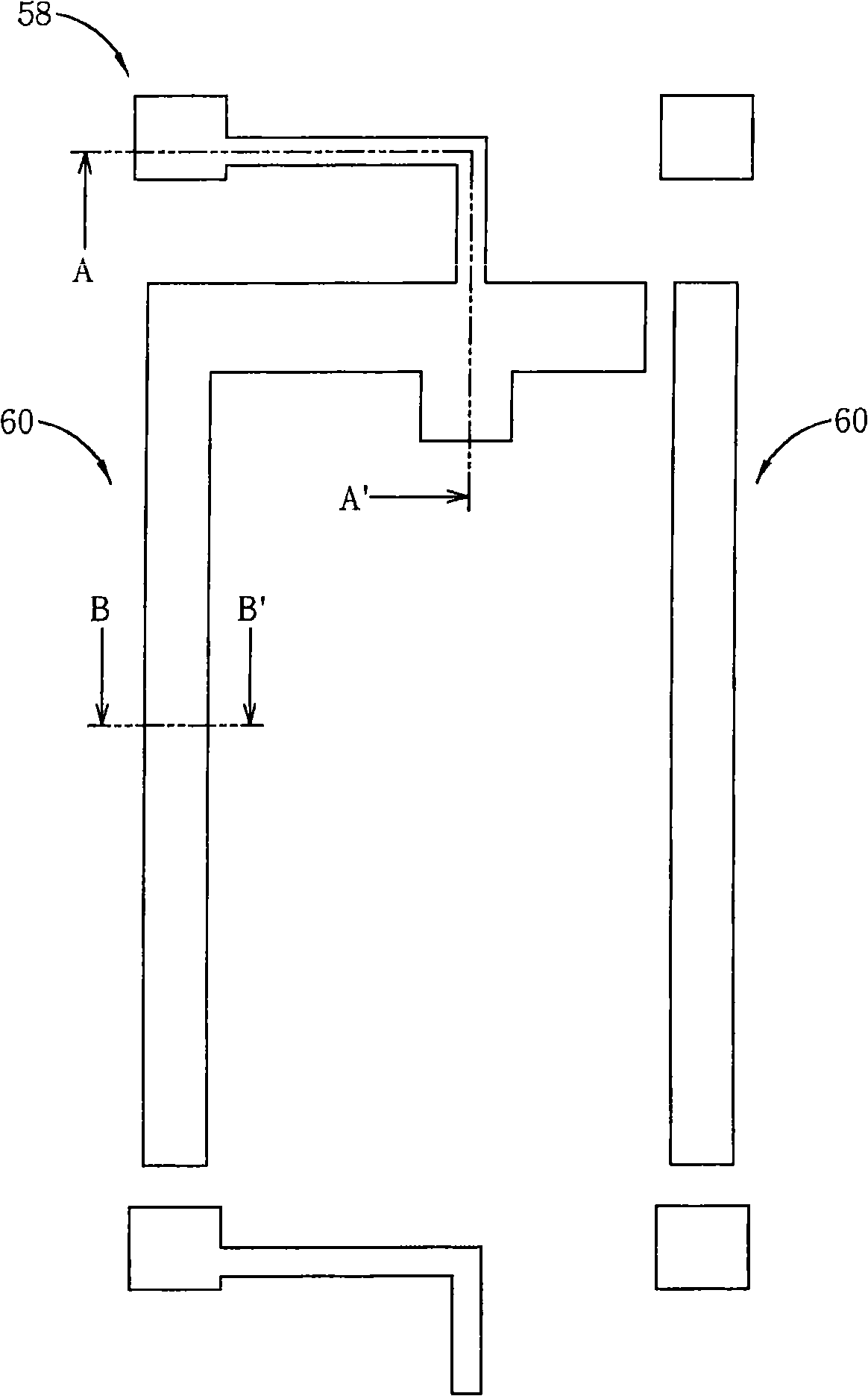

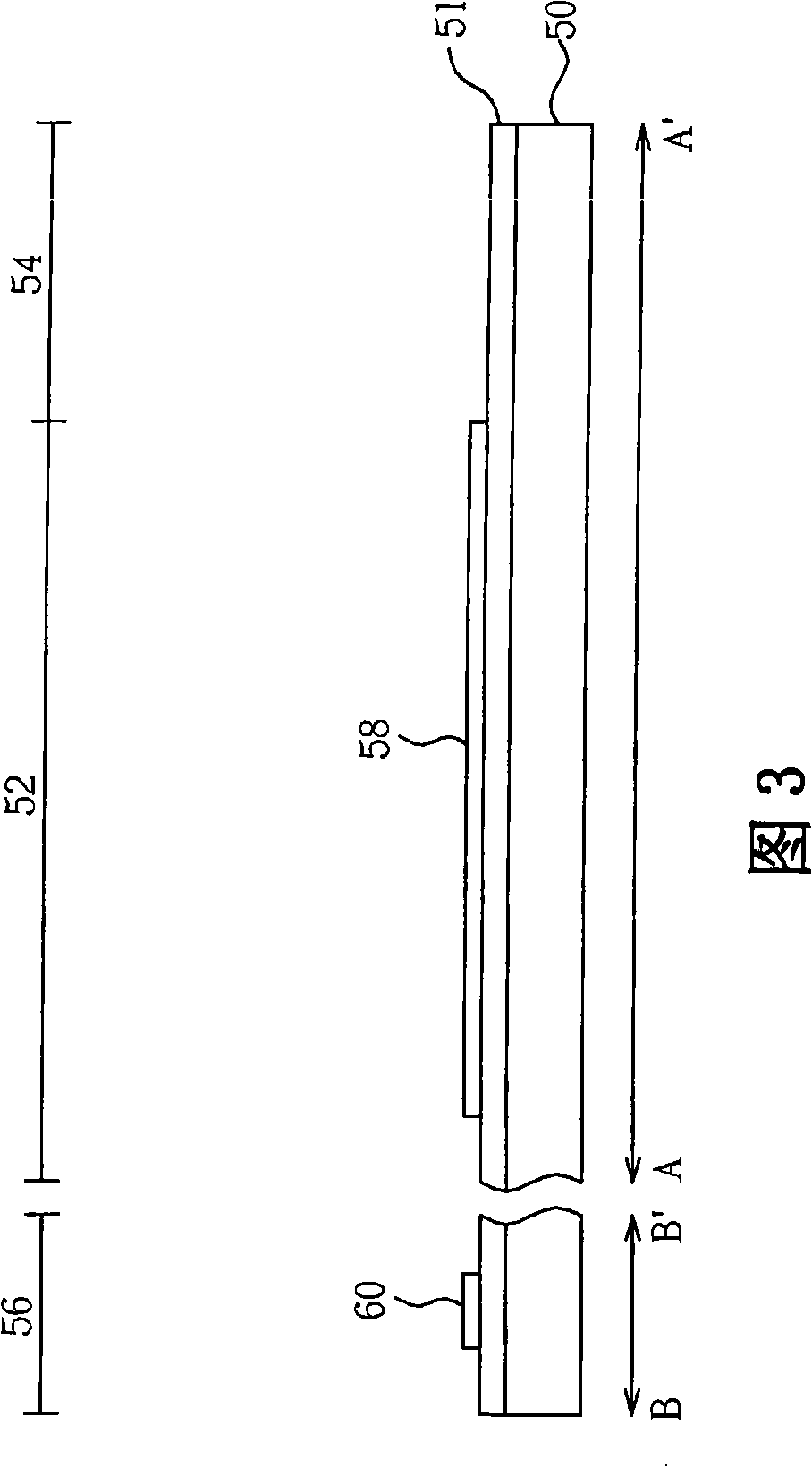

[0041] Please refer to figure 2 to Figure 17. figure 2 17 is a schematic diagram of a method for manufacturing a preferred embodiment of the transflective liquid crystal display panel of the present invention. For ease of illustration, only one pixel area is shown in the drawings, and figure 2 , Figure 4 , Figure 6 , Figure 8 , Figure 10 , Figure 12 , Figure 14 and Figure 16 3, 5, 7, 9, 11, 13, 15 and 17 are schematic cross-sectional views of the pixel region along the section lines AA' and BB'. Such as figure 2 As shown in FIG. 3 , firstly, a substrate 50 is provided, and a reflective region 52 , a transmissive region 54 and a peripheral region 56 are defined ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap