Metallic element carbon hot melting reduction continuous reactor

A metal element and reactor technology, applied in the field of metallurgical materials, can solve problems such as low conversion efficiency, waste of resources, and increased emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

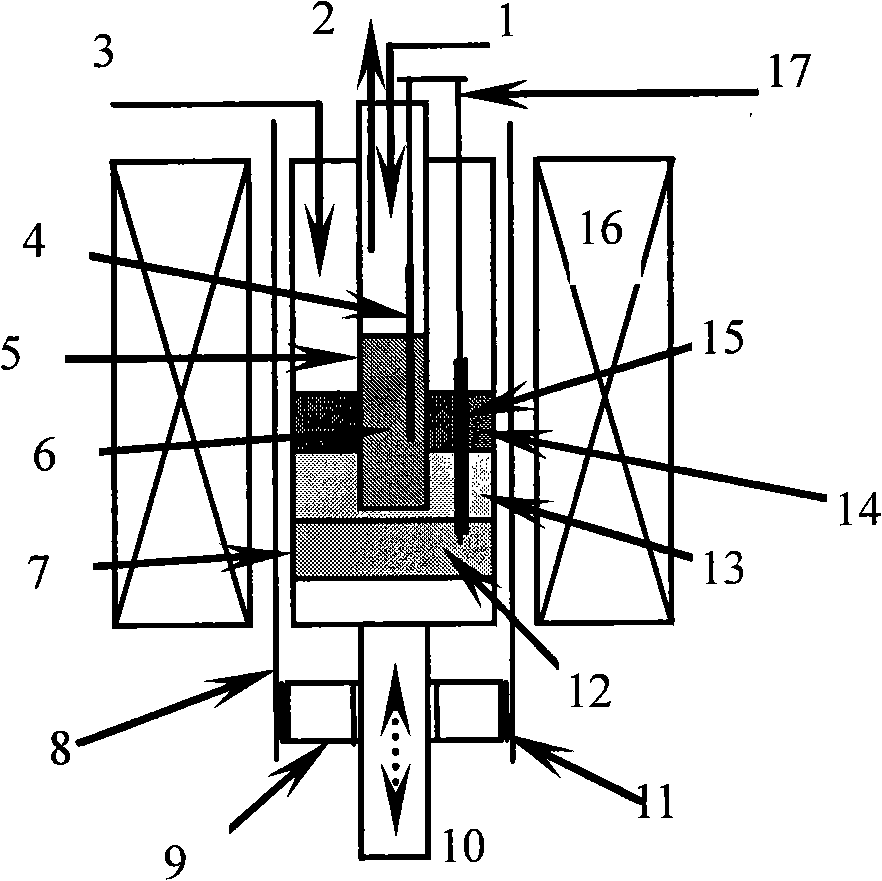

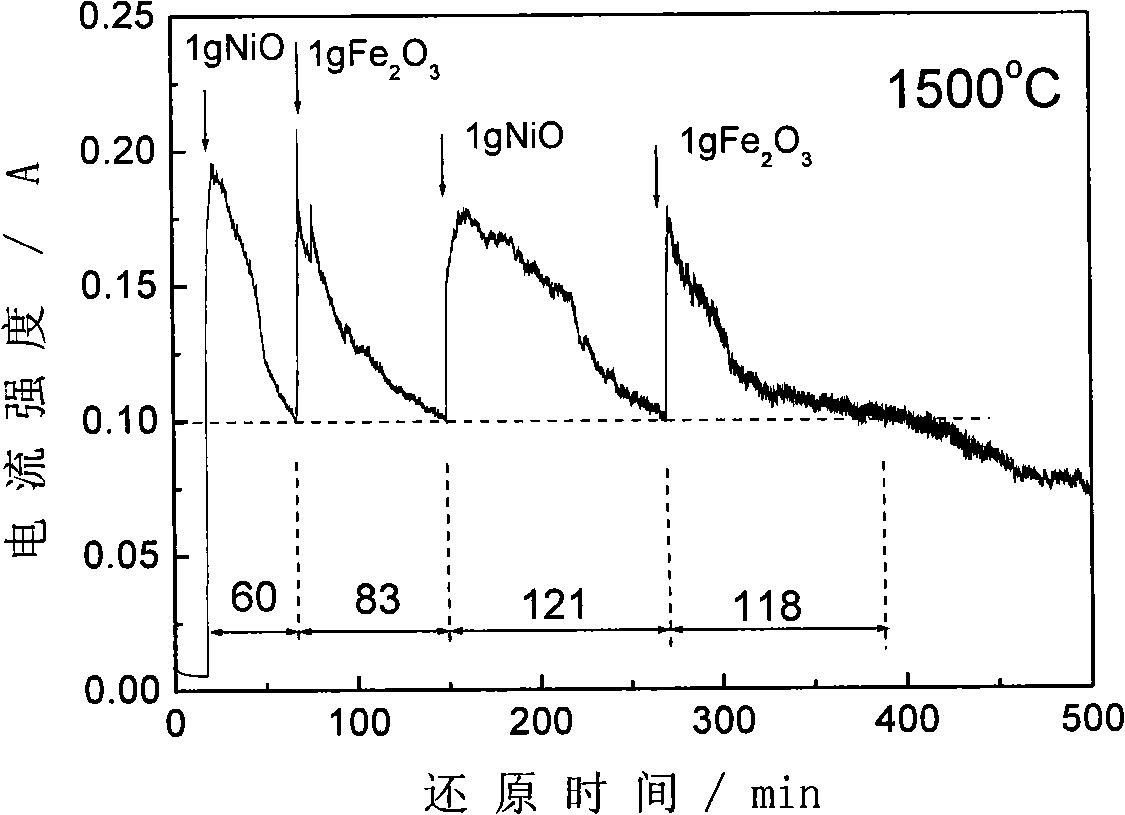

[0026] Specific examples, as attached figure 1 As shown, the oxygen ion conductor tube 5 is a MgO-stabilized zirconia tube, the liquid metal anode 6 is a carbon-saturated Fe-C melt, the crucible 7 is a corundum crucible, the atmosphere protection tube 8 is a fused alumina tube, and the initial cathode is selected For liquid silver, slag 14 choose 25% CaO-7% MgO-58% SiO 2 -10%Al 2 o 3 Mother slag, the electrode connection protection tube 15 is made of corundum material, and the electrode connection 17 is made of φ1.5mm molybdenum wire. During operation, first add 1g NiO sintered block for reduction at 1500°C under Ar atmosphere, and then add 1gFe when the current intensity of the external circuit is equal to 100mA 2 o 3 Sintered blocks for reduction. Similarly, in turn, when the current intensity of the external circuit reaches 100mA, add 1g NiO and 1gFe respectively 2 o 3 Sinter the block until the reduction is completed, that is, the current intensity of the external c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com