Tube-type sewage water micro-filter processing equipment

A technology for treating equipment and sewage, which is applied in water/sewage treatment, water/sludge/sewage treatment, ultrafiltration, etc. It can solve the problems of cumbersome, unfavorable operation, and inability to effectively maintain the quality of water production, so as to ensure the effect of water production , Guarantee the effect of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

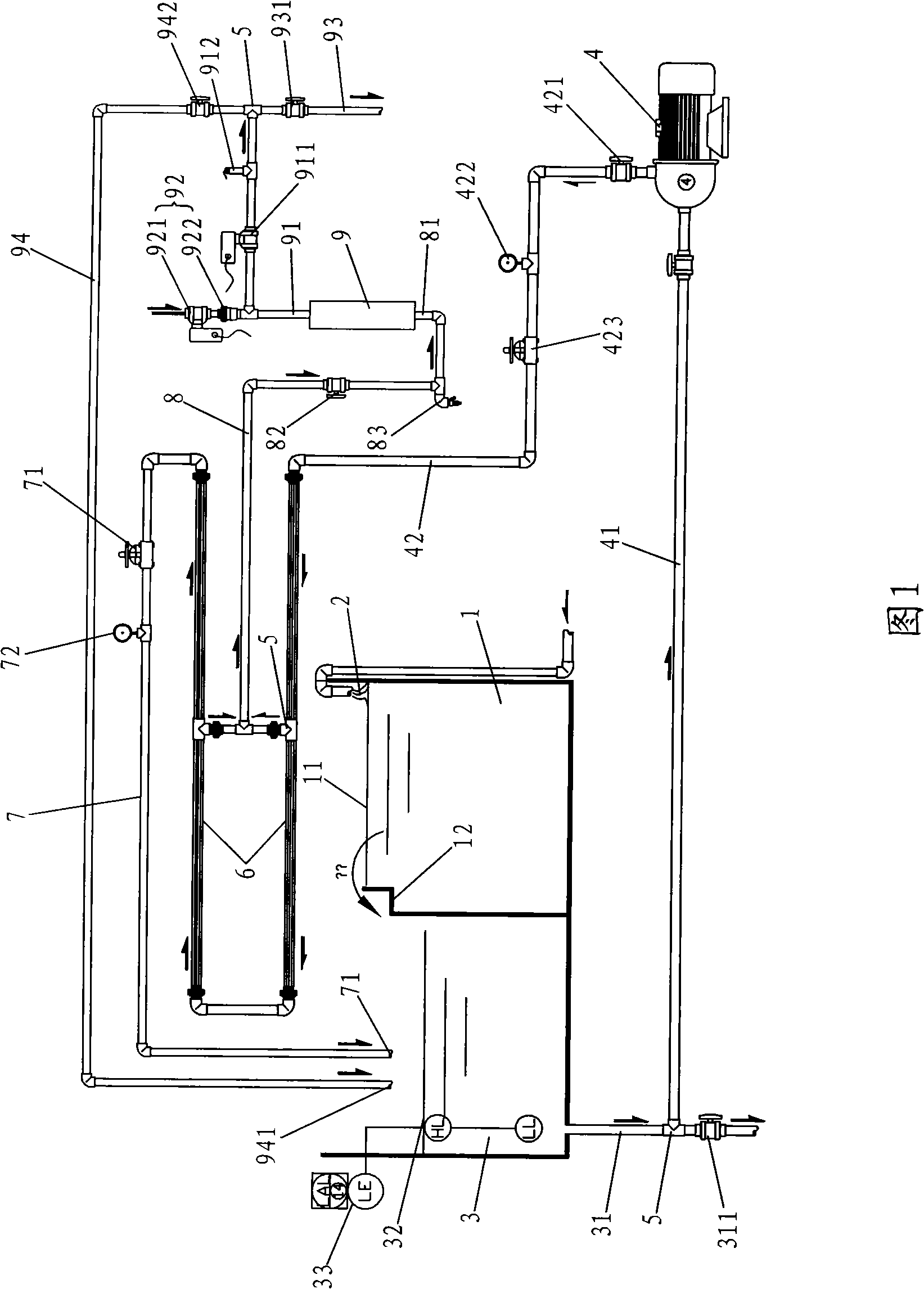

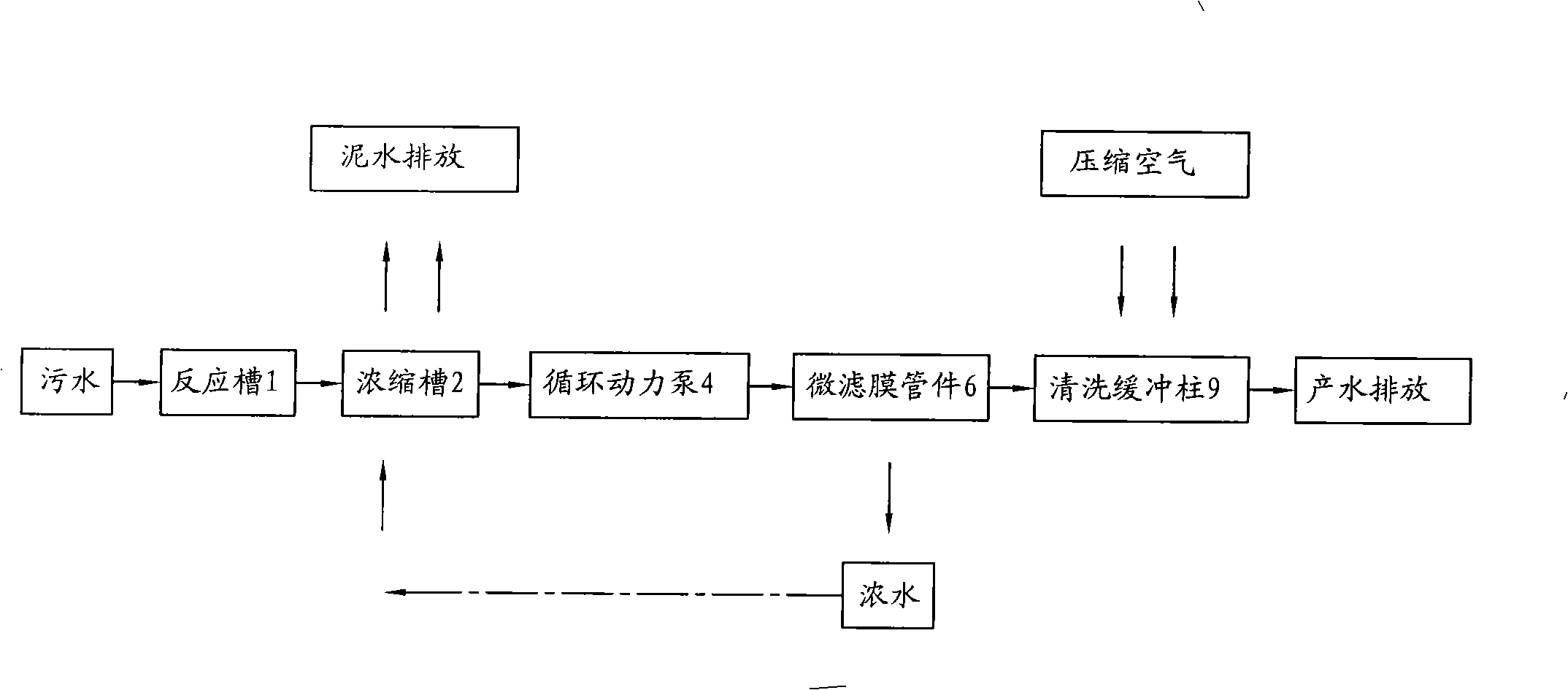

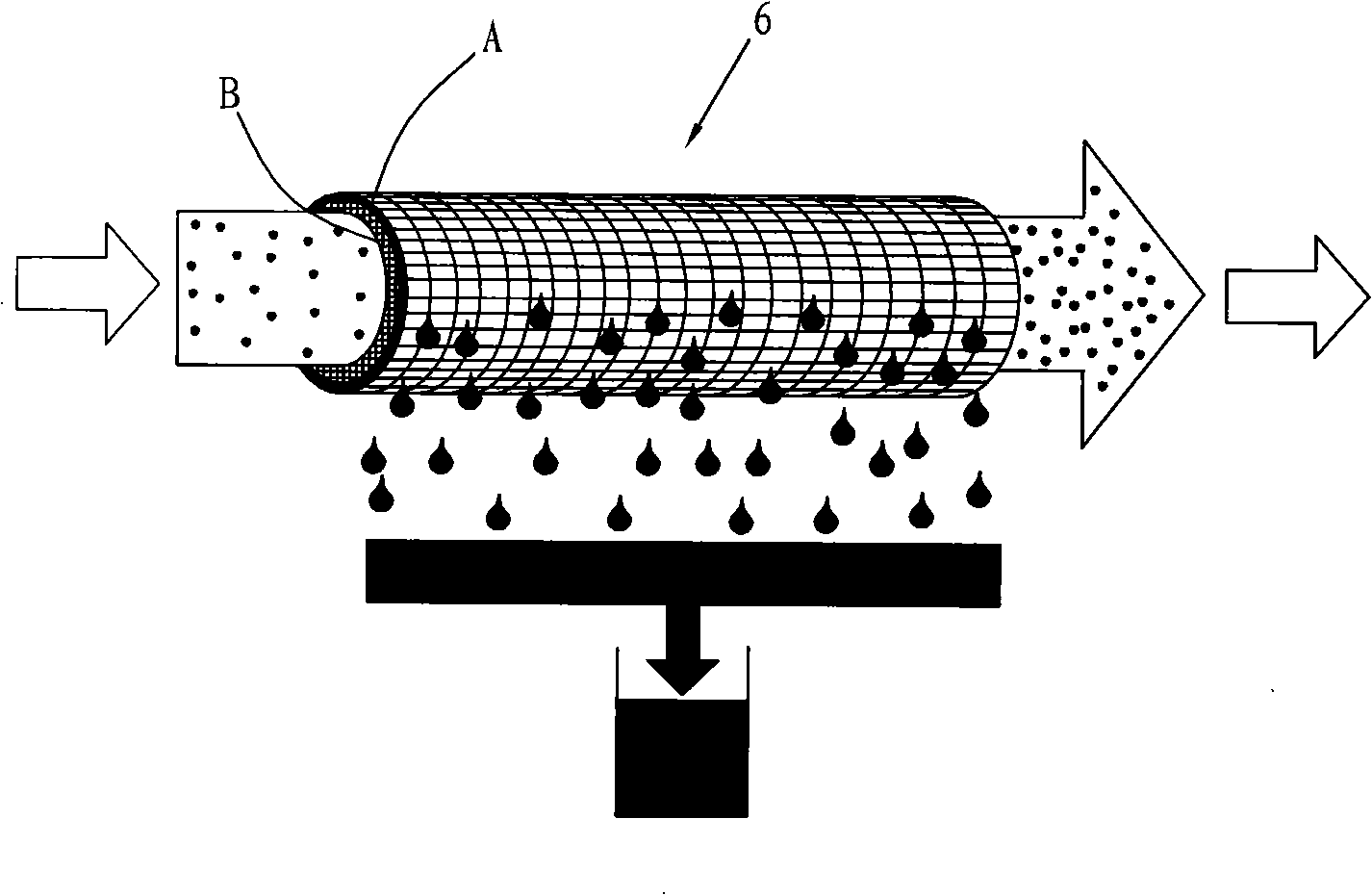

[0017] As shown in Figure 1, a tubular sewage microfiltration treatment equipment includes a reaction tank 1, a concentration tank 3, a microfiltration membrane pipe fitting 4, a circulating power pump 6 and a cleaning buffer column 9, wherein:

[0018] Reaction tank 1, sewage pipe mouth 2 is arranged at the notch 11 above the reaction tank 1, in the reaction tank, the sewage in the reaction tank can form the largest particle suspension, and play a pretreatment role; for example, in the reaction tank 1 Some medicaments can be added in the sewage to form the largest particle suspension in the sewage, which will greatly improve the filtration efficiency of the subsequent microfiltration membrane pipe fitting 4. When the system is in operation, the water inflow to the reaction tank 1 is controlled to be equivalent to the water output of the system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com