Method for using domestic garbage incineration flyash as decolorizing material of industrial dye waste water

A technology of domestic waste incineration and dye wastewater, applied in the direction of adsorption water/sewage treatment, etc., can solve the problem of high cost of activated carbon production and regeneration, achieve the goal of harmless wastewater, and reduce the effect of chromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

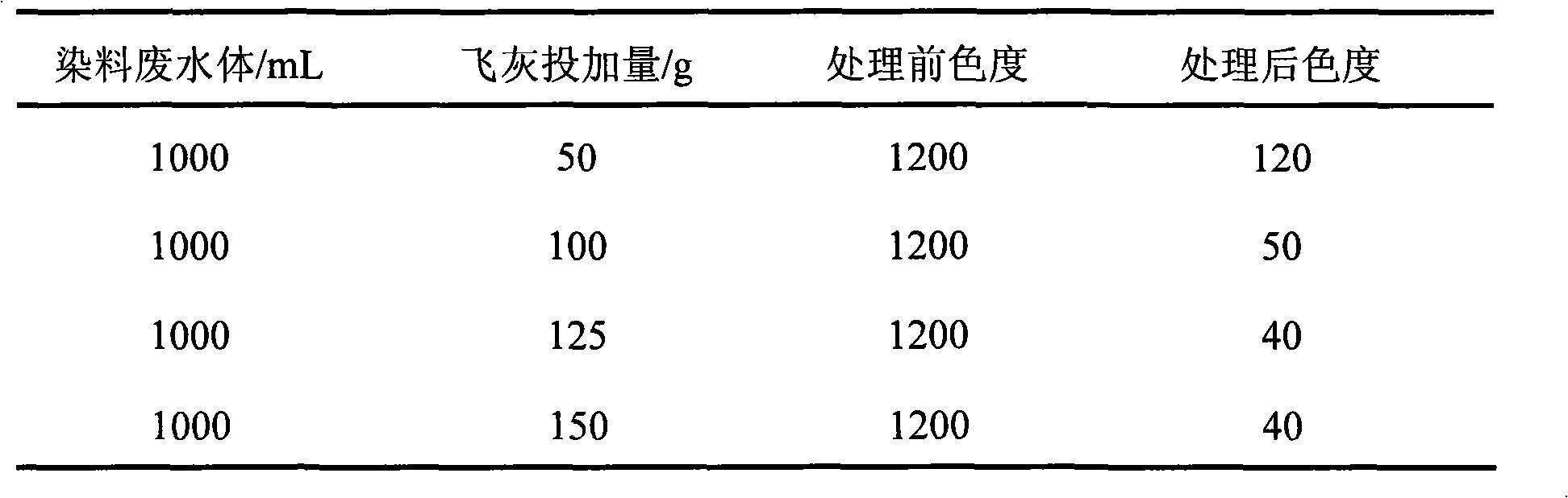

[0013] Under normal temperature and pressure conditions, add 1000mL of dark blue dye wastewater from a cotton spinning and dyeing factory into four beakers, weigh 50g, 100g, 125g, and 150g of domestic waste incineration fly ash dried at 105°C for 24 hours and put them into the beakers.

[0014] Table 1 The decolorization effect of different fly ash dosages on dye wastewater

[0015]

[0016] The fly ash particle diameter is 30-150um, and 50% of the fly ash particle diameter is distributed in the range of 38.5-74um. Start the electric mixer to mix the fly ash and industrial dye wastewater evenly. After stirring for 30 minutes, let it stand for 30 minutes to separate the fly ash from the dark blue dye wastewater, and analyze the chroma of the treated dye wastewater. The experimental results are shown in Table 1.

Embodiment 2

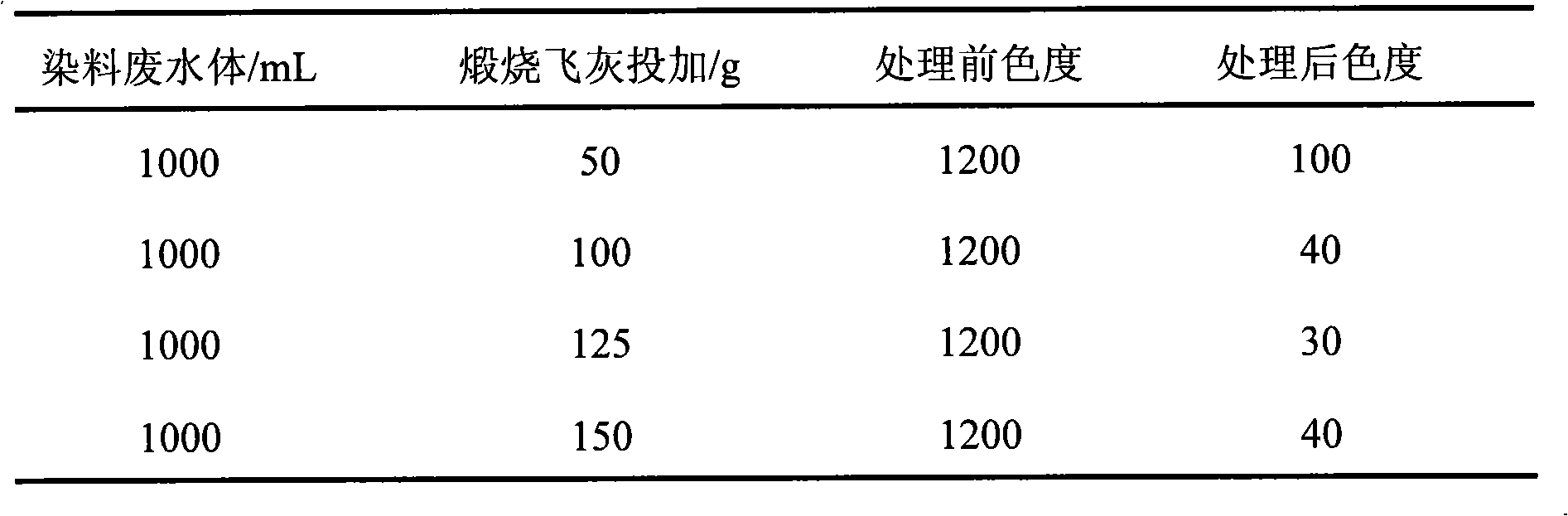

[0018] Under normal temperature and pressure conditions, add 1000mL of dark blue dye wastewater from cotton spinning and printing and dyeing factories into four beakers respectively, weigh 50g, 100g, 125g, and 150g of domestic waste incineration fly ash calcined at a high temperature of 500°C and put them into the beakers Among them, the fly ash particle diameter is 30-150um, and 50% of the fly ash particle size distribution is within the range of 38.5-74um. Start the electric mixer to mix the fly ash and industrial dye wastewater evenly. After stirring for 30 minutes, let it stand for 30 minutes, separate the calcined fly ash from the dark blue dye wastewater, and analyze the chroma of the treated dye wastewater. The experimental results are shown in Table 2.

[0019] Table 2 Effect of different fly ash dosages on decolorization of dye wastewater after high temperature calcination

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com