S type controlled-release urea and preparing method thereof

A technology of controlled release of urea and urea granules, which is applied in the direction of urea compound fertilizer, nitrogen fertilizer, fertilizer mixture, etc., can solve the problems of increasing equipment investment cost, not easy to obtain, and very high sealing requirements, and achieve excellent nutrient resistance control function, operation Simple and low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

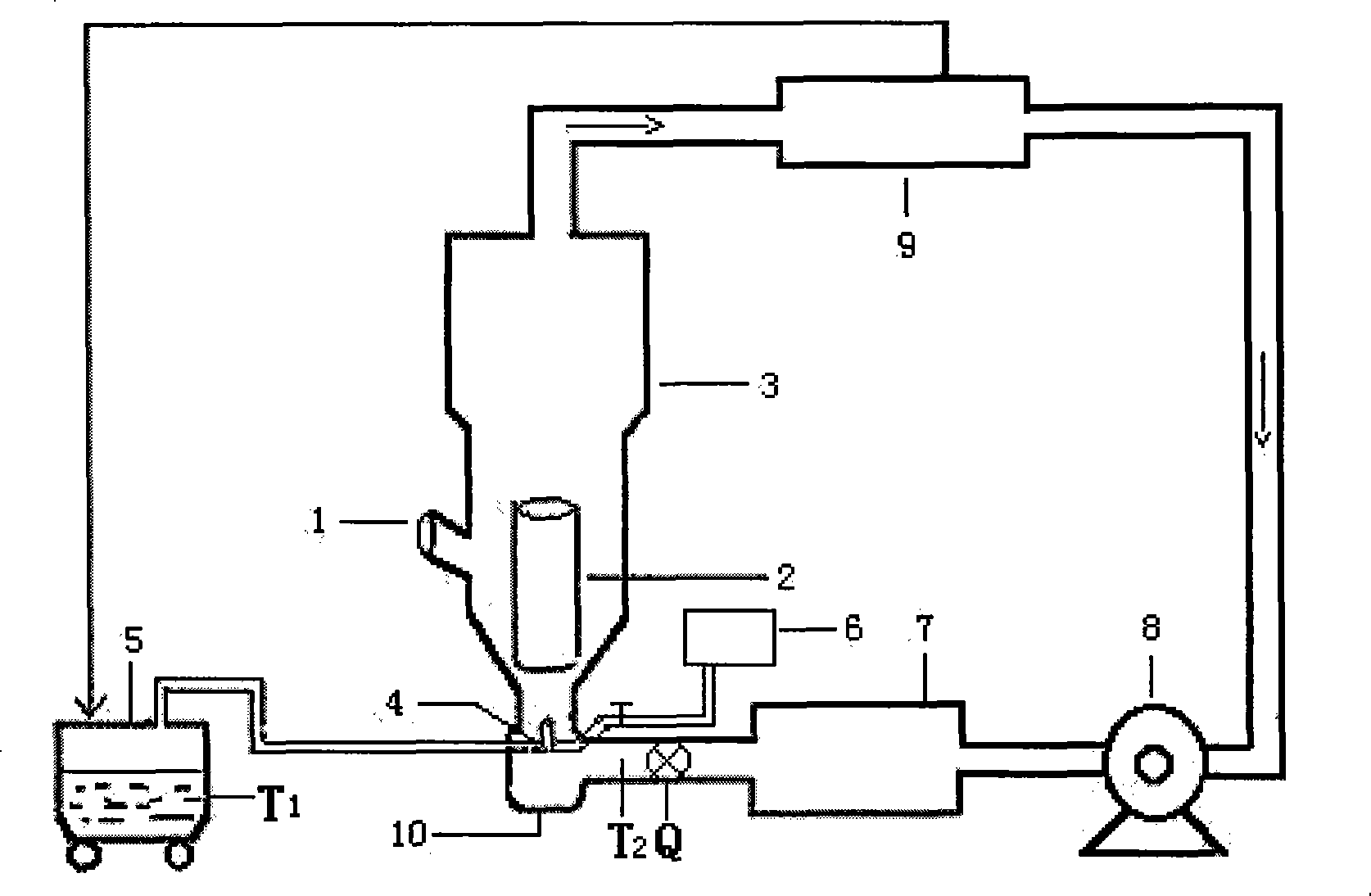

[0036] Example 1. Preparation of S-type controlled release urea

[0037] 1. Preparation of coating solution

[0038] Measure solvent turpentine oil (density 0.865g / cm 3 , Boiling point 158-162℃, origin Fujian) 2.50L added to dissolving irrigation ( figure 2 As shown in 5). Accurately weigh 40.0g of waste polystyrene foam (purchased by market waste recycling company), linear low-density polyethylene (injection grade, melt flow rate 0.7g / 10min; purchased from Sinopec) 30.0g, modified starch 5g (200-300 mesh, add modifier (aluminate coupling agent, produced by Fujian Normal University Polymer Experimental Factory) to corn starch in a high-speed mixer and heat it to a constant temperature of 110°C, keep it for 15-20 minutes, and then discharge That is to obtain modified starch), add the dissolving pot, stir and heat up to 130°C, heat and stir at constant temperature for about 1h, after the polymer is completely dissolved, add 70g talc (1500 mesh), heat up to 140°C and keep stirring ...

Embodiment 2

[0049] Example 2. Preparation of S-type controlled release urea

[0050] 1. Preparation of coating solution

[0051] Measure solvent turpentine oil (density 0.865g / cm 3 , Boiling point 158-162℃, origin Fujian) 3.00L was added to dissolving irrigation. Accurately weigh 40.0 g of waste polystyrene foam (purchased by a market waste recycling company), 10 g of low-density polyethylene (model-1F7B, melt flow rate 7.0g / 10min; purchased from Beijing Yanshan Petrochemical Company), linear low-density poly Ethylene (injection grade, melt flow rate 0.7g / 10min; purchased from Sinopec) 30.0g, modified starch 6g (200-300 mesh, add modifier (aluminate coupling) to corn starch in a high-speed mixer Coupling agent, produced by Fujian Normal University Polymer Experimental Factory) and heated to a constant temperature of 110 ℃, maintained for 15-20 minutes, the modified starch will be obtained after discharging), and add the dissolving pot together ( figure 2 5) After stirring and heating to 130...

Embodiment 3

[0055] Example 3 Preparation of S-type controlled release urea

[0056] 1. Preparation of coating solution

[0057] Measure solvent turpentine oil (density 0.865g / cm 3 , Boiling point 158-162℃, origin Fujian) 3.00L was added to dissolving irrigation. Accurately weigh 40.0 g of waste polystyrene foam (purchased by a market waste recycling company), 10 g of low-density polyethylene (model-1F7B, melt flow rate 7.0g / 10min; purchased from Beijing Yanshan Petrochemical Company), linear low-density poly Ethylene (injection grade, melt flow rate 0.7g / 10min; purchased from Sinopec) 30.0g, modified starch 5g (200-300 mesh, add modifier (aluminate couple) to corn starch in a high-speed mixer Coupling agent, produced by Fujian Normal University Polymer Experimental Factory) and heated to a constant temperature of 110 ℃, maintained for 15-20 minutes, the modified starch will be obtained after discharging), and add the dissolving pot together ( figure 2 5) After stirring and heating to 130°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com