Resin-coated urea and preparation method thereof

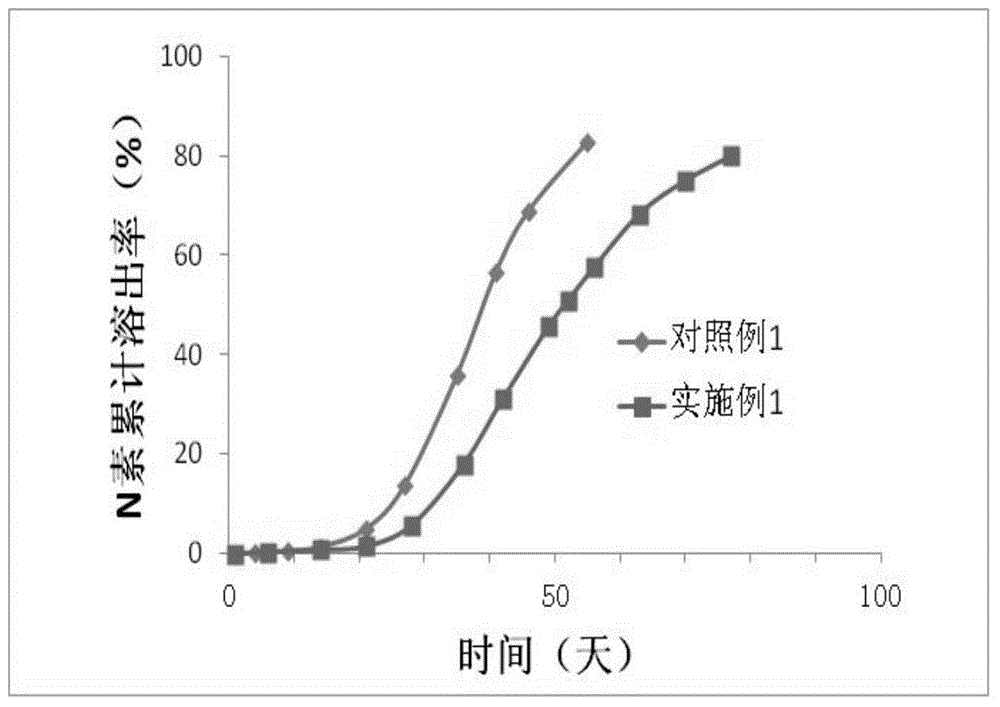

A technology of resin coating and urea, applied in the direction of urea compound fertilizer, layered/coated fertilizer, nitrogen fertilizer, etc., to achieve the effects of making up for surface defects, prolonging the release period, and reducing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Preparation of resin-coated urea

[0028] Weigh 13g polystyrene (purchased from Beijing Yanshan Petrochemical, model is 666D, melt index is 8g / 10min), 14.6g low-density polyethylene (purchased from Beijing Yanshan Petrochemical, model is LD100AC, melt index is 2g / 10min), 18.3g linear low-density polyethylene (purchased from Yangzi Petrochemical, model 1801, melt index 1g / 10min), 24.1g talcum powder and 3.2g starch, mixed in 1.8L tetrachlorethylene solvent at 120-130°C Obtain the coating solution.

[0029] Place 1 kg of urea granules in the spray tower, control the temperature of the dry hot air at 90-100° C., and 10 g of polymethylene polyphenyl polyisocyanate (purchased from Bayer, Germany, brand Desmodur 44V20L) under the baking of hot air Added to the urea surface through a nozzle to form a pre-coat. After 1 minute, the above-mentioned coating solution was sprayed onto the surface of the suspended and fluidized urea particles through a nozzle, and after t...

Embodiment 2

[0033] Example 2 Preparation of resin-coated urea

[0034] Weigh 31.3g polystyrene (purchased from Beijing Yanshan Petrochemical, model is 666D, melt index is 8g / 10min), 6.8g low-density polyethylene (purchased from Beijing Yanshan Petrochemical, model is 1F7B, melt index is 7g / 10min) , 29.9g linear low density polyethylene (purchased from Tianjin Petrochemical, model is 9085, melt index is 0.7g / 10min), 54.4g talcum powder and 13.6g starch, in 1.95L turpentine solvent, mix at 130-140 ℃ Obtain the coating solution.

[0035] Put 1 kg of urea granules in the spray tower, control the temperature of the dry hot air at 90-100 °C, add 1 g of liquefied MDI (purchased from Yantai Wanhua, model PMM-10) to the surface of the urea through the nozzle under the support of the hot air , forming a precoat. After 1 minute, the coating solution was sprayed onto the surface of the suspended and fluidized urea particles through a nozzle, and the solvent was volatilized to prepare a coated ferti...

Embodiment 3

[0036] Example 3 Preparation of resin-coated urea

[0037] Take by weighing 31.4g polystyrene (purchased by waste recycling companies in the market), 20.2g low-density polyethylene (purchased from Beijing Yanshan Petrochemical, the model is LD160AS, and the melt index is 4g / 10min), 21.3g linear low-density polyethylene ( Purchased from Tianjin Petrochemical, model is 9085, melt index is 0.7g / 10min), 31.4g talcum powder and 7.8g starch, mixed in 2.2L turpentine solvent at 130-140°C to obtain coating solution.

[0038] Put 1kg of urea granules in the spray tower, control the temperature of the dry hot air at 90-100°C, and add 6g of toluene diisocyanate to the surface of the urea through the nozzle under the heating of the hot air to form a pre-coating layer. After 1 minute, spray the above-mentioned coating solution onto the surface of the suspended and fluidized urea particles through a nozzle, and obtain a coated fertilizer with a coating rate of 10% after the solvent evaporat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com