Konstantan alloy baseband for high-temperature superconduction coating conductor

A technology of coated conductors and constantan alloys, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as limiting AC transmission applications, and achieve the effect of superior electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

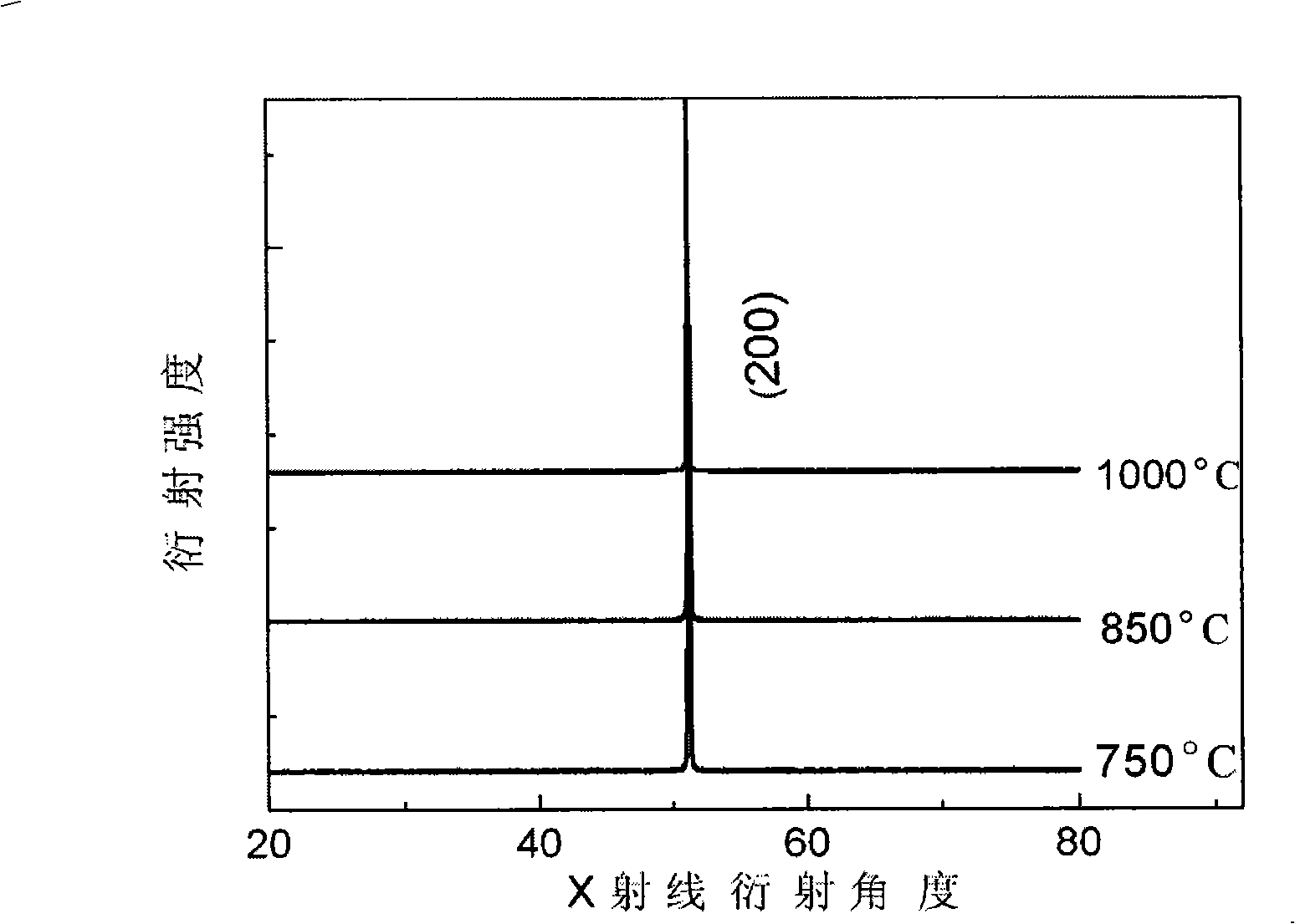

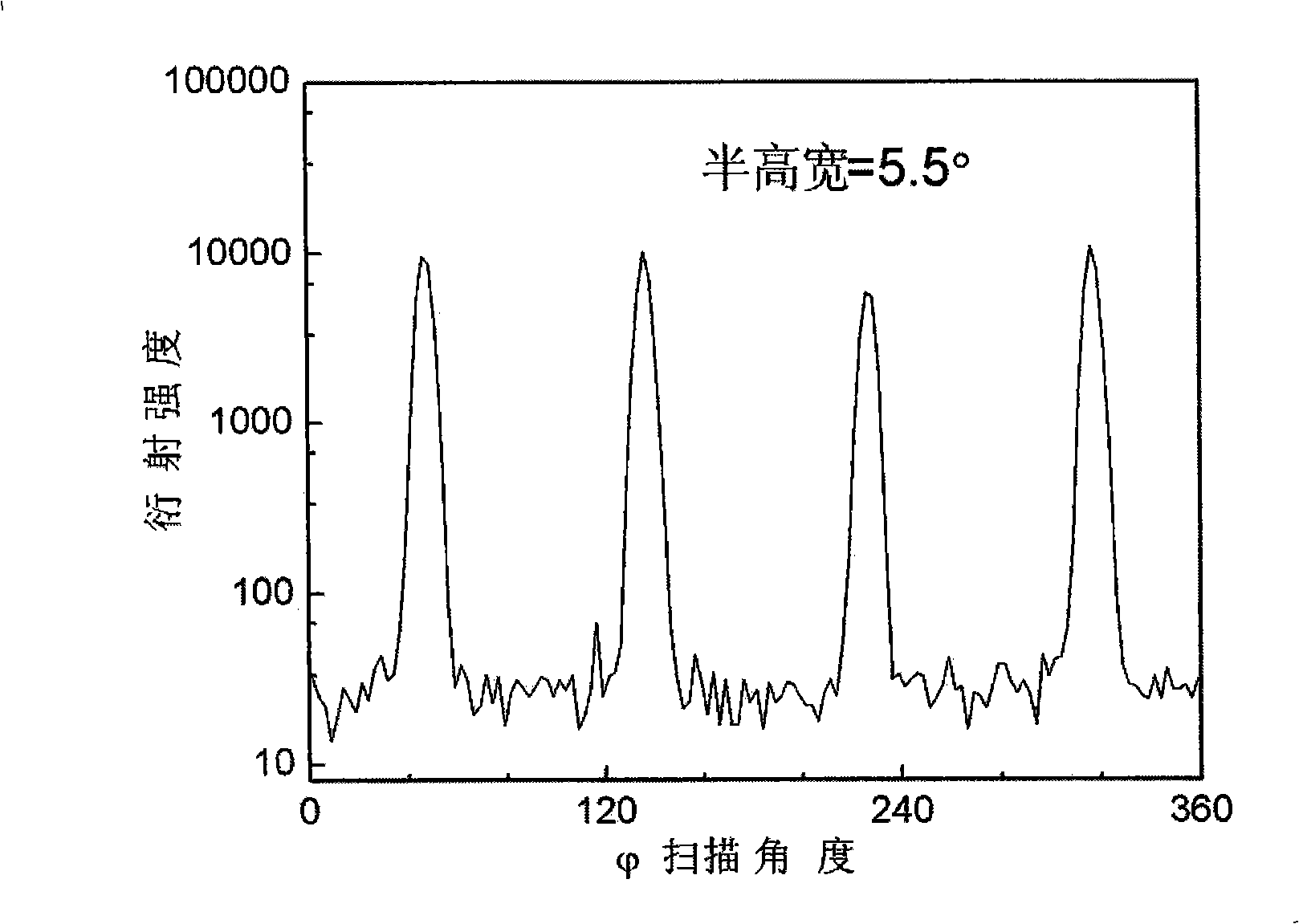

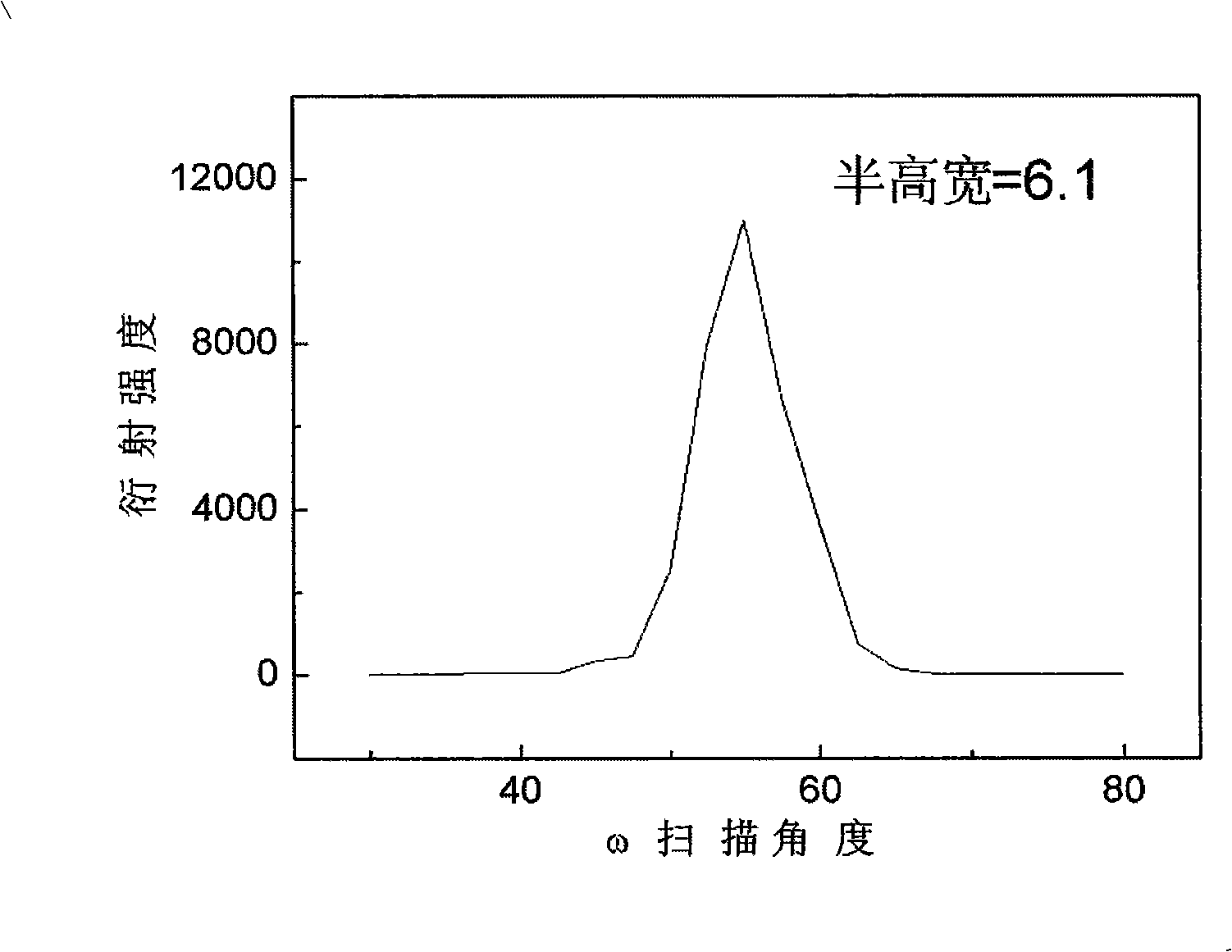

Method used

Image

Examples

Embodiment 1

[0020] In this embodiment, high-purity copper, nickel, and manganese-gold powders are used as raw materials.

[0021] The used copper, nickel and manganese metal powders are in the following proportions by weight: 60% of Cu, 38% of Ni and 2% of Mn.

[0022] In this embodiment, the preparation process and steps of the constantan alloy baseband are as follows:

[0023] (1) carry out batching according to above-mentioned chemical composition formula, take by weighing 600g of copper powder, 380g of nickel powder and 20g of manganese powder, be made into mixture; Melt by traditional conventional smelting process, form ingot through smelting and casting; Then cast ingot After forging and rolling to form billets.

[0024] (2) annealing the above-mentioned ingot at a temperature of 500° C. for 50 minutes under a mixed atmosphere of Ar+4% Hz;

[0025] (3) Rolling is carried out then, and the rolling deformation of pass is 5%, and total deformation is 98%; Obtain the alloy base strip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com