External heat insulation decorative processing method and structural body

A processing method and structure technology, applied in building construction, covering/lining, construction, etc., can solve the problems of single color, lack of conception, etc., and achieve the effect of excellent heat insulation and excellent aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0101] The examples shown below illustrate the features of the present invention more clearly.

[0102] (Manufacture of undercoat material 1)

[0103] 65 parts by weight of the following resin 1, 6.5 parts by weight of film-forming aids, 2.5 parts by weight of thickener, 14 parts by weight of titanium oxide 60% by weight dispersion, 1 part by weight of yellow iron oxide 60% by weight dispersion, 4.2 parts by weight A 50% by weight dispersion of black iron oxide, 6 parts by weight of water, and 0.8 parts by weight of an antifoaming agent were uniformly mixed by a common method to prepare an undercoating material 1 .

[0104] Resin 1: Multilayer structured synthetic resin emulsion

[0105] Outer layer: acrolein resin (Tg5°C, composition: methyl methacrylate, n-butyl acrylate, n-butyl acrylate, 2-ethylhexyl acrylate, methacrylic acid),

[0106] Inner layer: silicone resin (composition: hexamethylcycloylsiloxane, octamethylcyclotetrasiloxane, decamethylcyclopentasiloxane), acrol...

experiment example 1

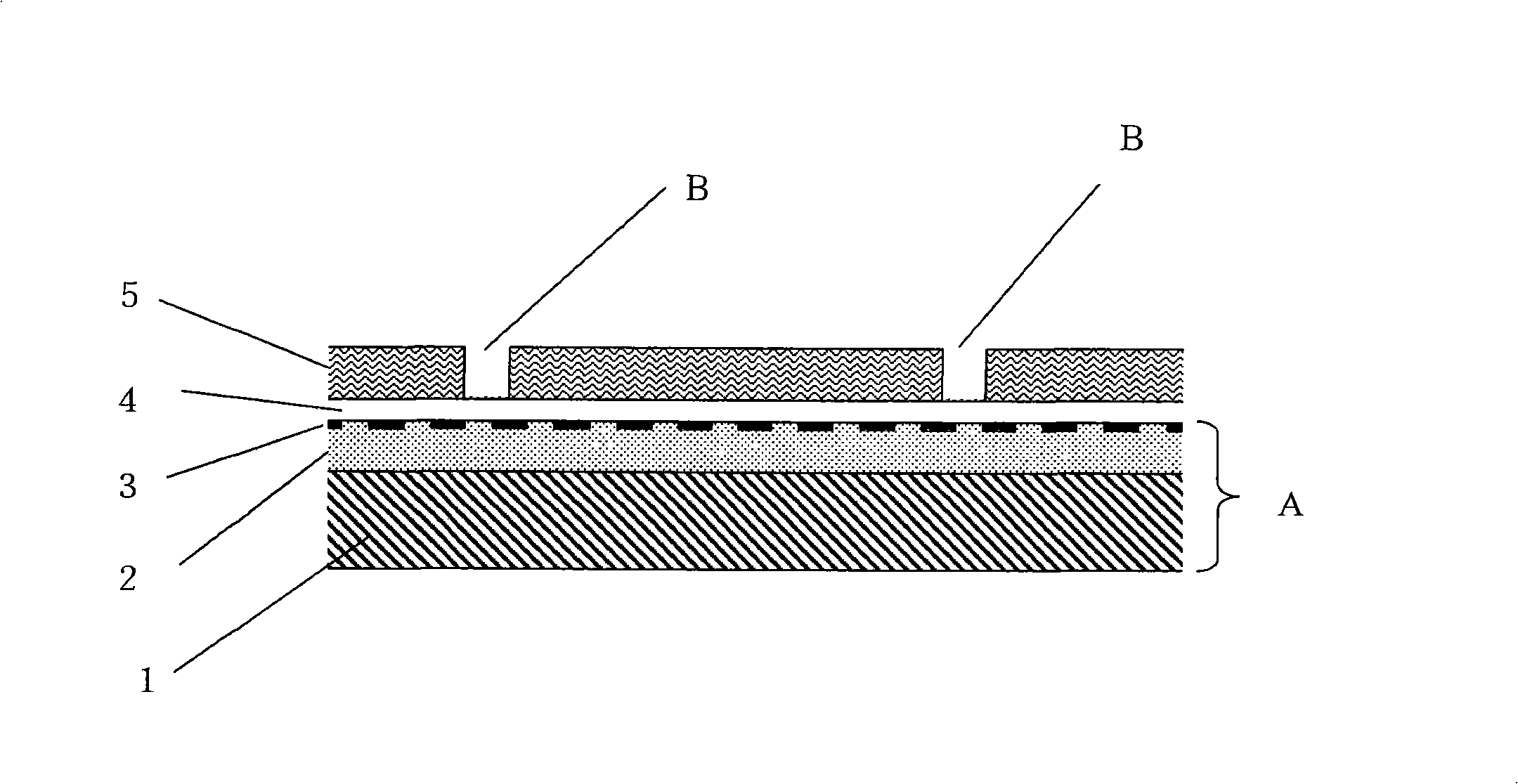

[0137] Paste plate-shaped polystyrene foam on the stone board to form a heat-insulating material layer, and then coat it with a coating amount of 0.5kg / m 2 The mud, the mud consists of 20 parts by weight of active phenol A type epoxy resin, 20 parts by weight of amine hardener, 100 parts by weight of Portland cement, 80 parts by weight of talcum powder, 80 parts by weight of titanium oxide, 30 parts by weight of water, additives 1 part by weight. Further, a glass mesh is laminated on it, and then coated with a coating amount of 0.5kg / m 2 The slurry is used to form a reinforcement layer, which is used as the substrate to be painted.

[0138] The total spray coating amount of the substrate is 0.3kg / m 2 Undercoat material 1, after maintenance for 2 hours, stick a rod-shaped joint material (joint width 10mm, height 5mm, made of polyethylene) into a grid with an adhesive, and then spray it as a decorative coating material. The coating amount is 0.4 kg / m 2 The multi-color patter...

experiment example 2

[0141] A wall surface structure was obtained in the same manner as in Example 1 except that the undercoat material 1 was used instead of the undercoat material 2 . The resulting surface, in a checkered pattern based on gray seams, is colorful in black and brown and exhibits excellent aesthetics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com