Vertical shaft wind motor

A wind turbine and vertical axis technology, applied in the field of machinery, can solve problems such as low wind energy utilization coefficient, poor self-starting performance, and burnt out generators, so as to improve wind energy utilization rate, reduce wind sweeping area, and increase sweeping wind area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

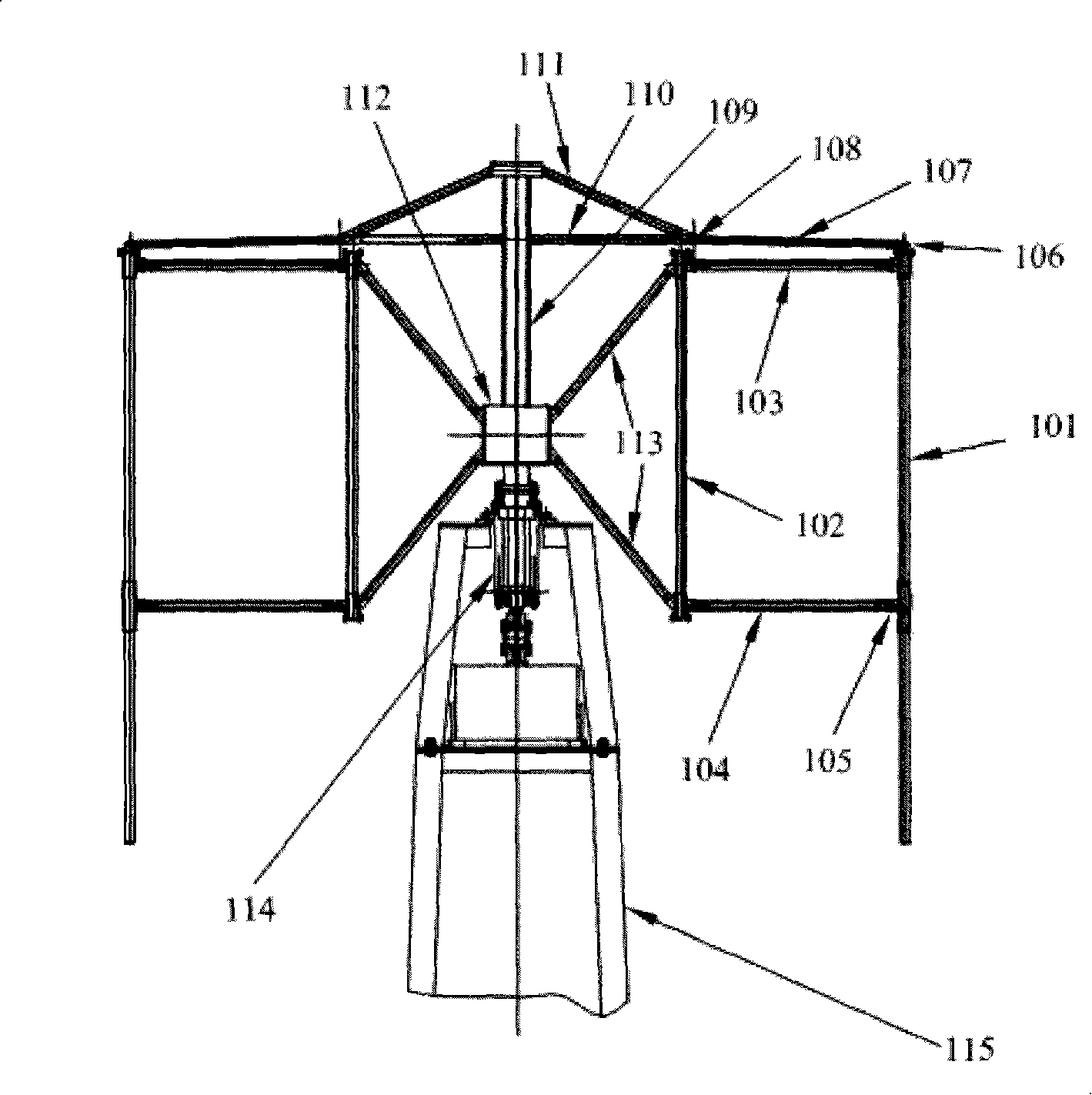

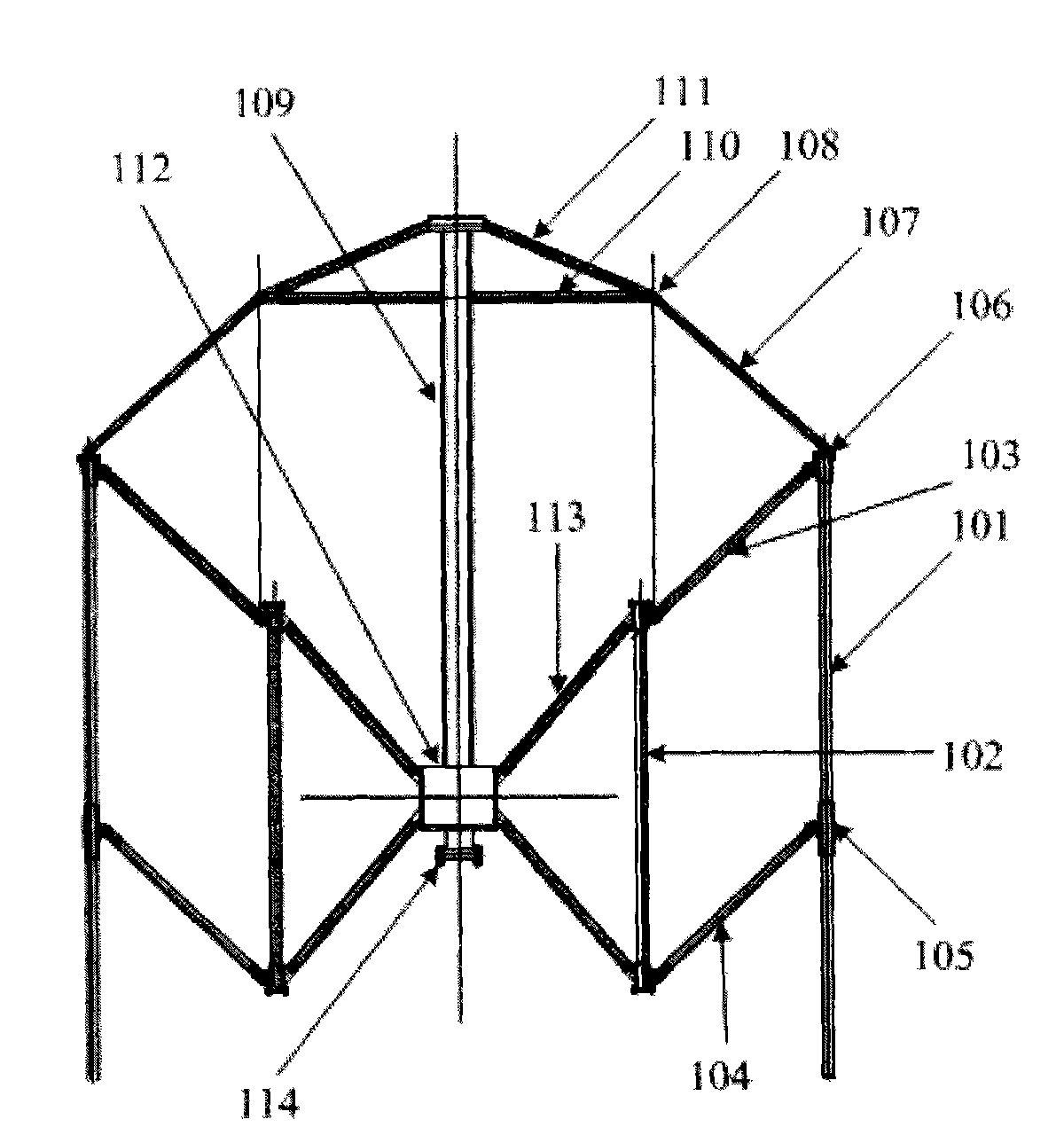

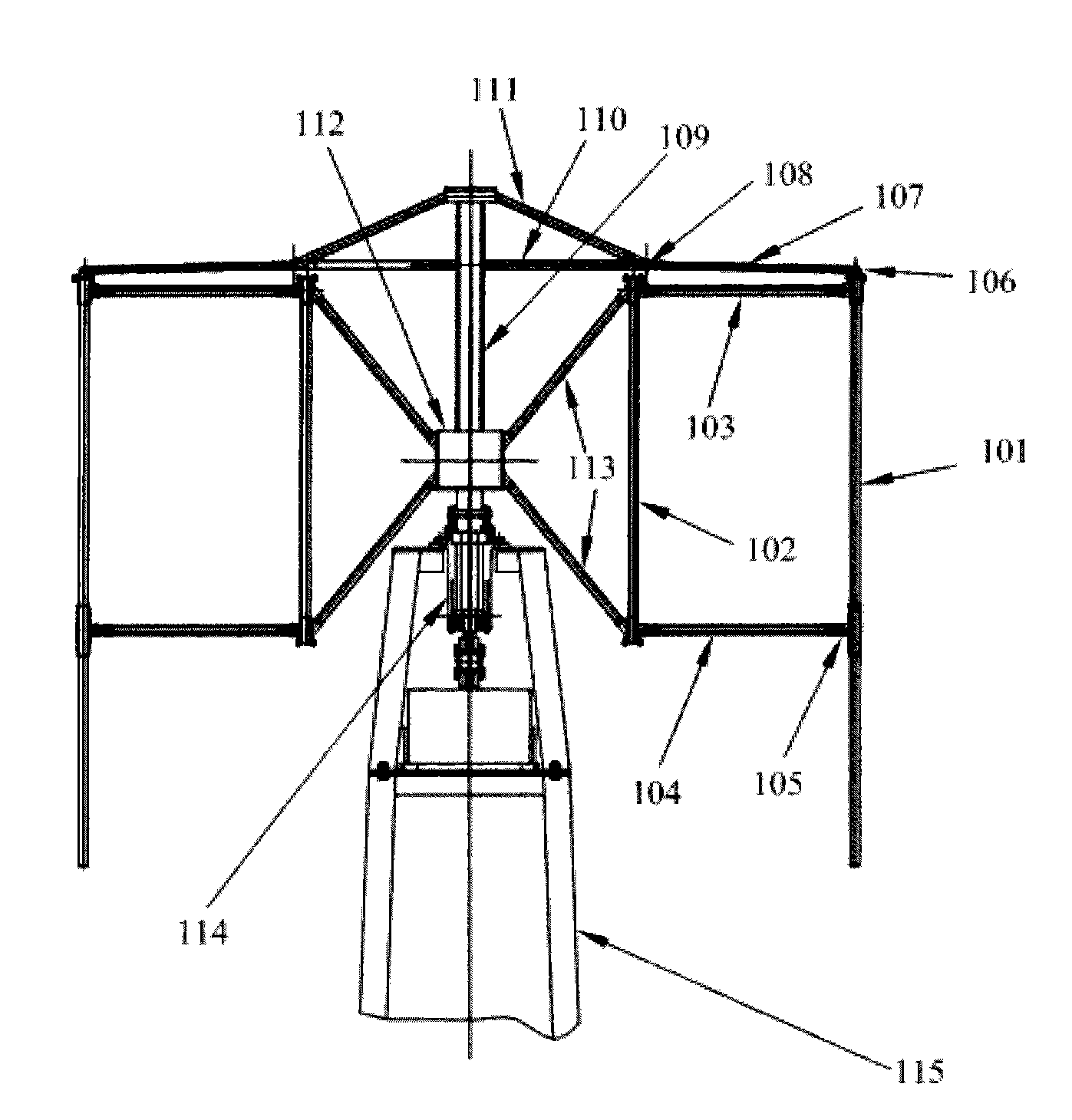

[0029] An embodiment of the present invention provides a vertical axis wind turbine, which is used for effectively utilizing wind force and reasonably controlling the power output of the wind rotor.

[0030] The wind turbine in this embodiment includes the following components:

[0031] Main blades, connectors, shafts, control systems, support shafts and towers;

[0032] The main blade is connected to the support shaft through a connector, the main blade is parallel to the support shaft, and can perform circular motion around the support shaft;

[0033] The rotating shaft and the supporting shaft are concentric shafts, the rotating shaft is sleeved outside the supporting shaft, the bottom end of the supporting shaft is connected with the control system, and can move up and down according to the control of the control system;

[0034] The connector is foldable. When the support shaft moves upward, the connector is stretched, and the main blade approaches the support shaft. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com