Multifunctional loading unit for objective table of microscope

A loading device and stage technology, applied in the field of mechanical devices, can solve the problems of not being able to place too heavy objects, narrow space, affecting the three-dimensional motion accuracy of the stage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

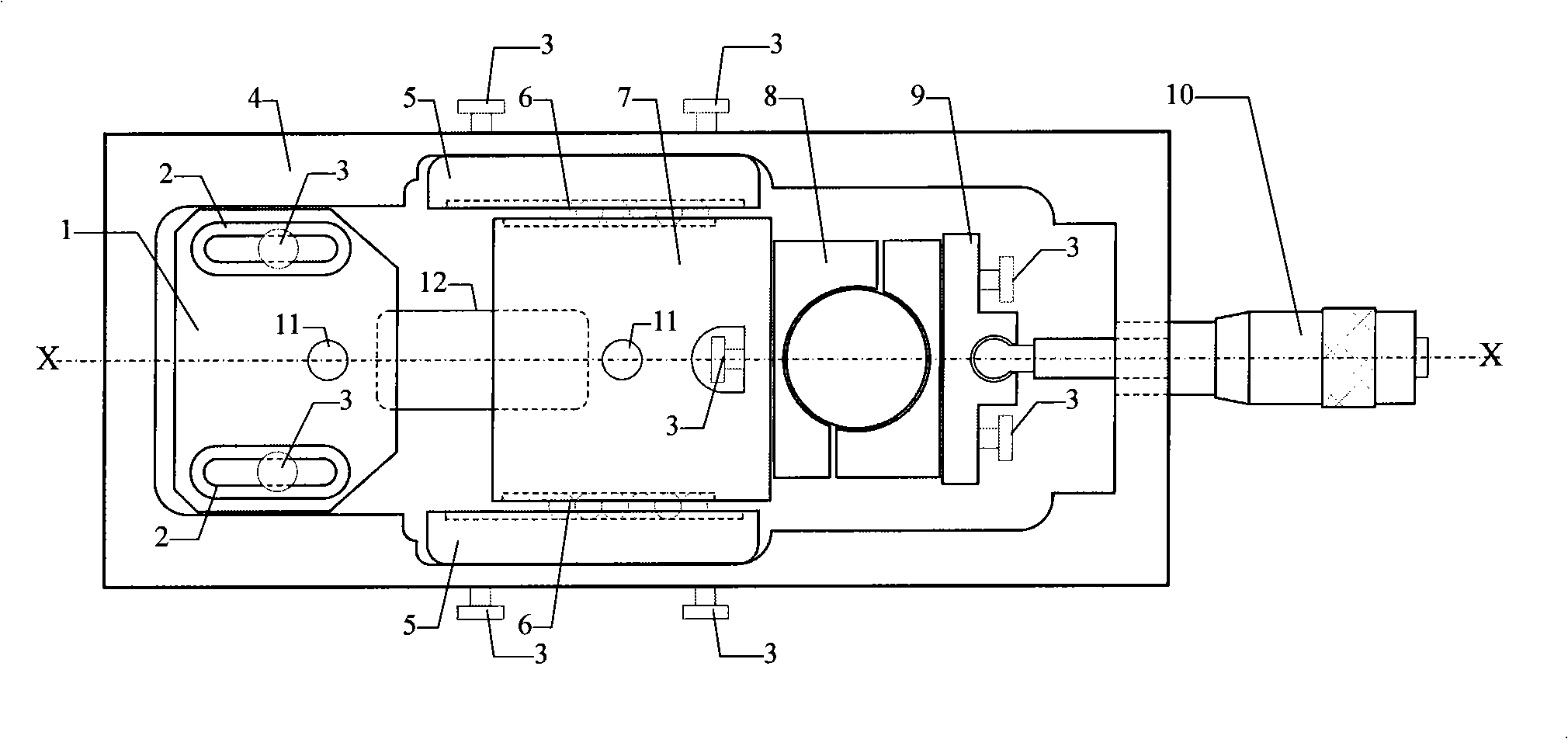

[0007] The present invention will be further described below through specific operation methods. Assemble the parts according to the structure shown in the accompanying drawing. The specific operation method is: the two ends of the sample on the stage are respectively fixed on the fixed clamp block 1 and the movable clamp block 7 by the test piece bolts 11. Since the centers of the test piece bolts 11 are located on the central axis X, the The multifunctional loading device performs non-eccentric uniaxial tension or compression load on the specimen.

[0008] Adjust the position of the fixed clamp 1 according to the size of the sample and fix it, and at the same time adjust the micrometer screw to reserve a loading displacement margin; check the initial value of the force sensor 8, and make the load return to zero by adjusting the micrometer screw 10, and record this time The scale of the micrometer screw 10 is used as the relative zero displacement position; the loading devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com