Method for producing animal protein feedstuff by processing restaurant garbage using angleworm

A technology for animal protein feed and kitchen waste, which is applied in the field of biodegradation and disposal of kitchen waste, can solve the problems of epidemic transmission of zoonotic diseases, secondary environmental pollution, etc., and achieves low infrastructure and operation costs and high safety. , the effect of improving profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

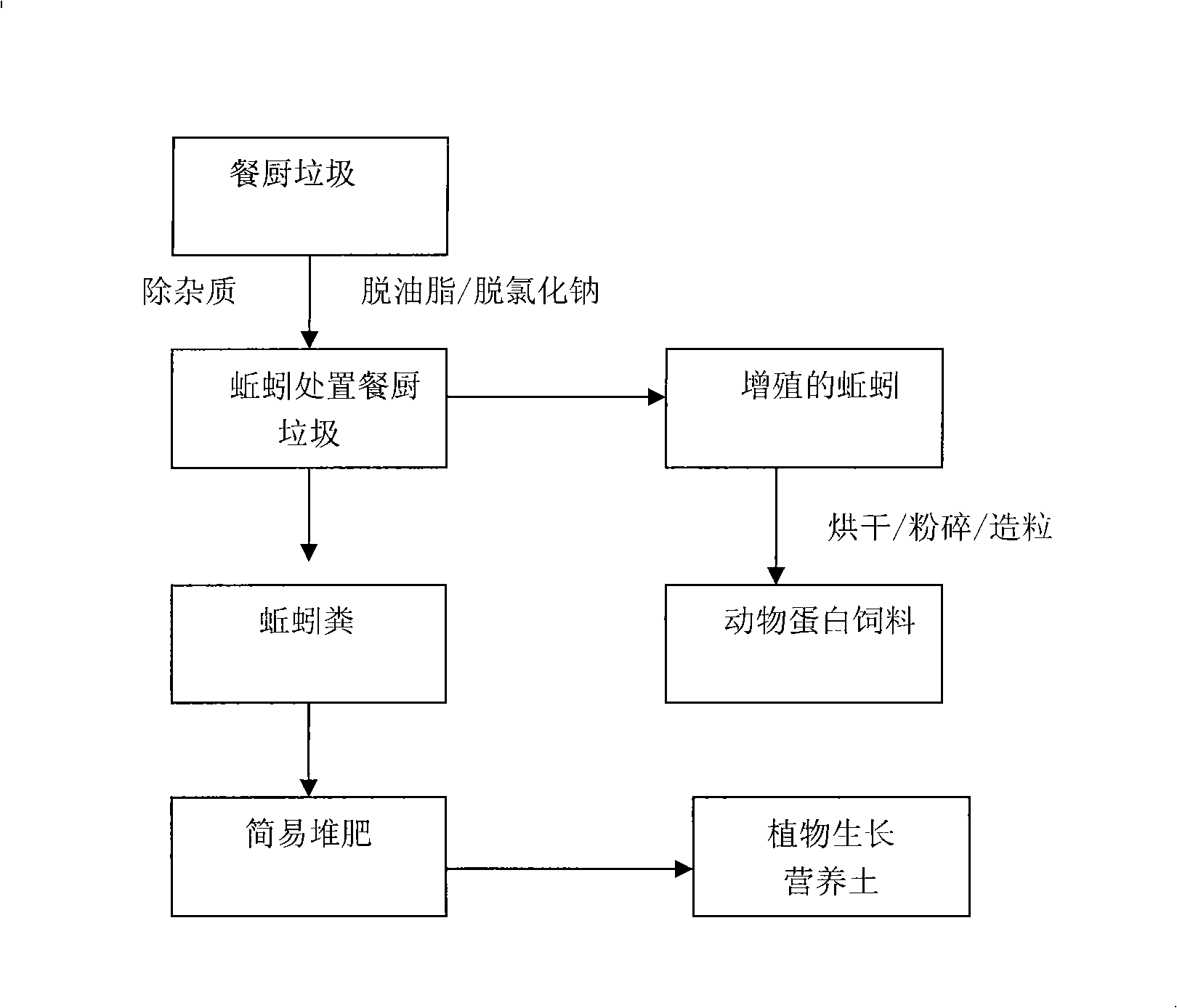

[0021] The kitchen waste of the present invention is hotel leftover meals and kitchen waste. The earthworm is the "Taiping No. 1" earthworm produced in Japan. see figure 1 : First put the collected food waste on a vibrating sieve for sieving treatment to remove bones, plastics, iron cans, gravel, and bamboo sticks. The vibrating screen has a vertical amplitude of 1-2cm, a vibration frequency of 800-1000 times per minute, and a sieve hole diameter of 2-3cm. The undersize after removing impurities by the vibrating screen enters the continuous feeding and discharging horizontal centrifuge for centrifugation, and the rotation speed of the continuous feeding and discharging horizontal centrifuge is 2600-2900rmp. The food waste obtained by centrifugation has a water content of 78-82%, an oil content of 1-8% of the food waste (wet weight), and a sodium chloride content of 0.1-0.6% of the food waste (wet weight). Then in the farmland of 20m×20m, excavate 30-80cm deep trenches, each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com