Preparation method of conductive silver composite nano particles coated by polypyrrole

A technology of composite nanoparticles and composite particles, which is applied in the field of nanomaterials and can solve problems such as decreased electrical conductivity, loss of electrical conductivity, and short circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

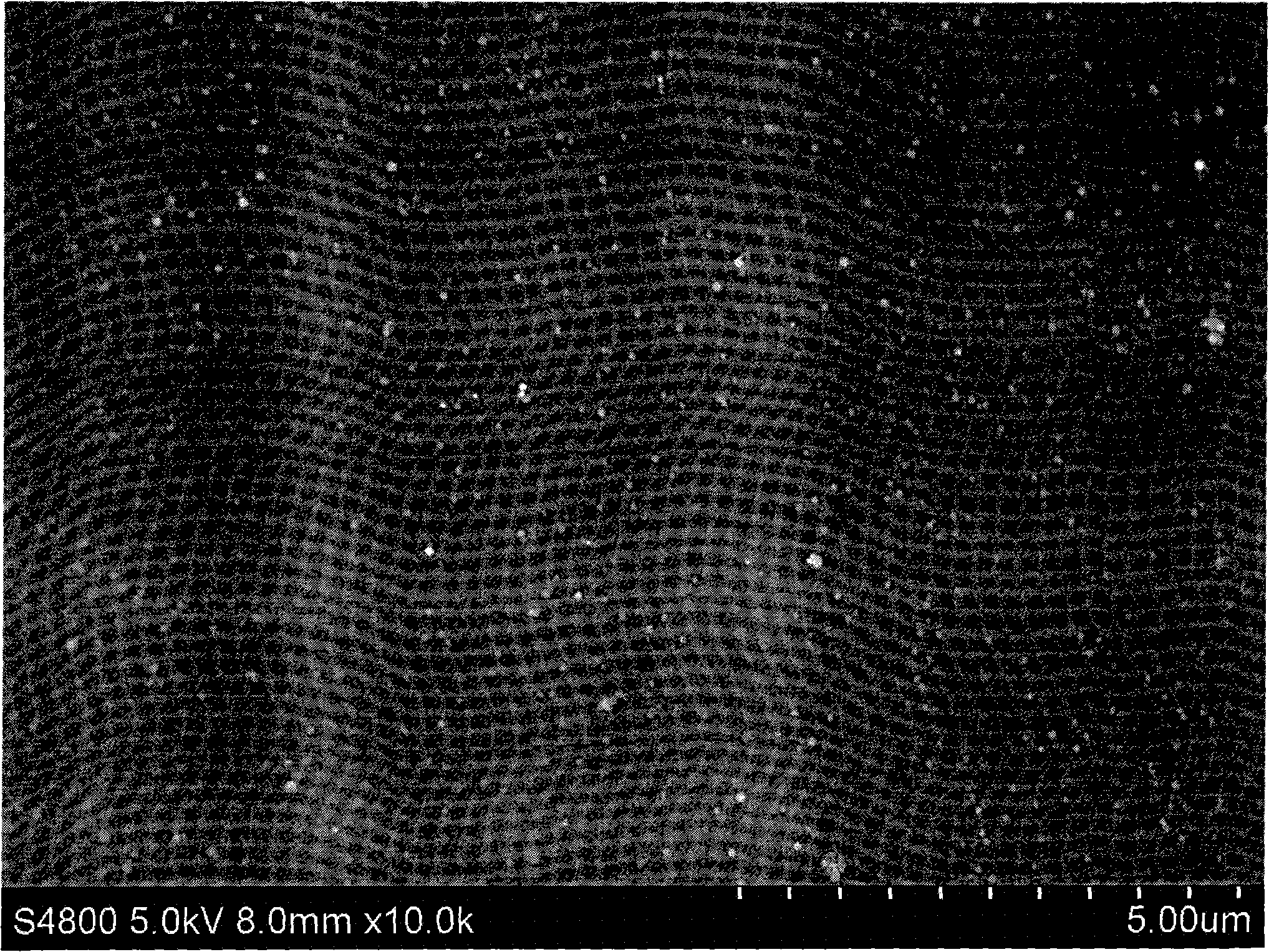

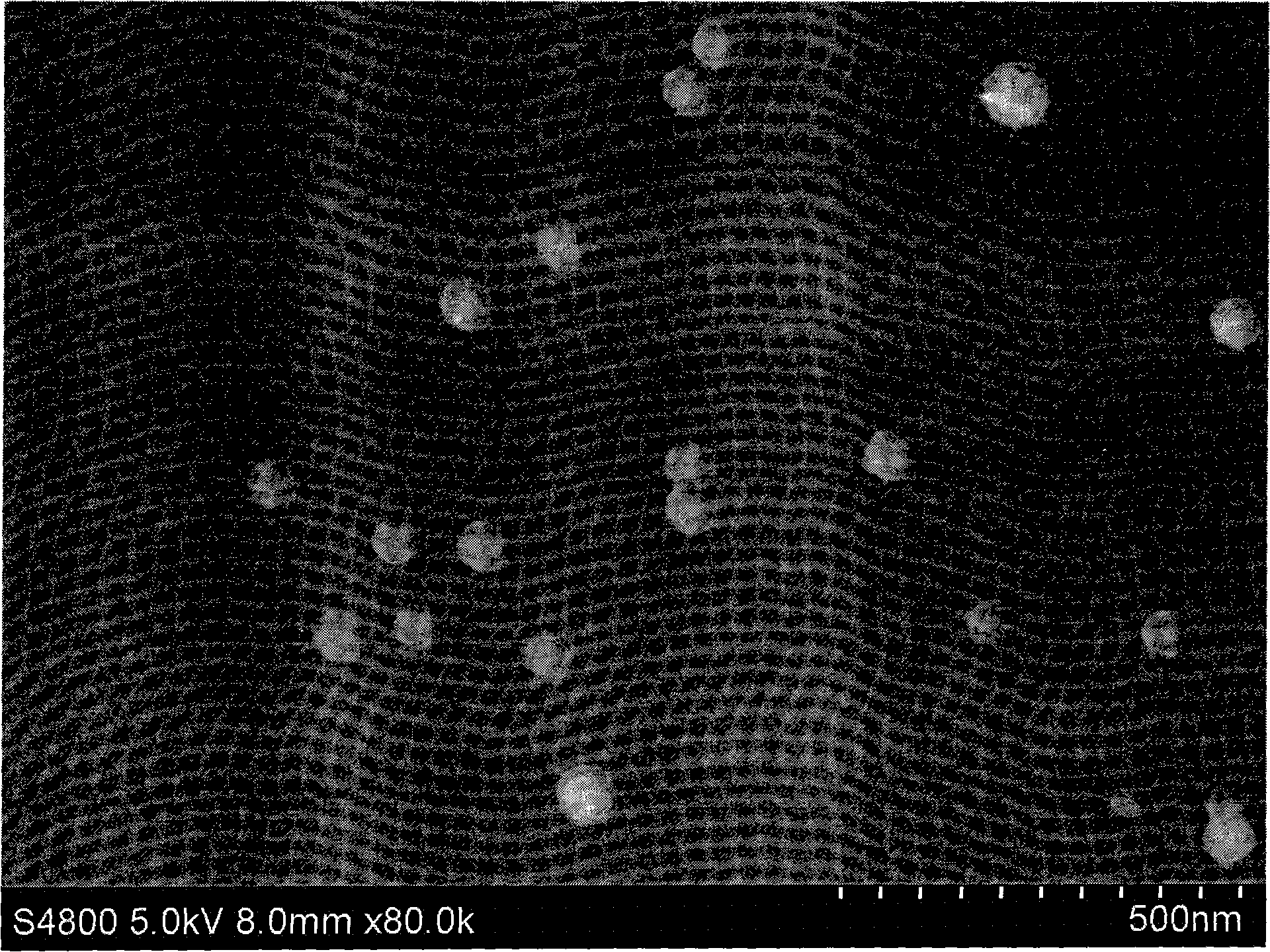

[0009] Embodiment 1, preparation concentration is the CuSO of 0.2mol / L 4 Solution, add CTAB and SDS compound surfactant, the concentration of the compound surfactant is 5mM and 1mM respectively, put the mixed solution in a 50°C incubator, stir for several minutes, then add 0.2mol / L pyrrole solution into In the reactor, use 1mol / L hydrochloric acid solution to adjust the pH to about 3, and then add AgNO after reacting for 24 hours. 3 solution, the added AgNO 3 solution with CuSO 4 The molar ratio of the solution was 1:10. The obtained mixed solution is centrifuged, washed with water three times, and dried in a vacuum oven to obtain spherical composite nanoparticles with a particle size of 40-60nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com