Fire retardant phosphorus-containing epoxy powder composition

A technology of epoxy powder and composition, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems that cannot be applied to powder systems, etc., and achieve the effects of broad market prospects and potential, stable performance indicators, and simple synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

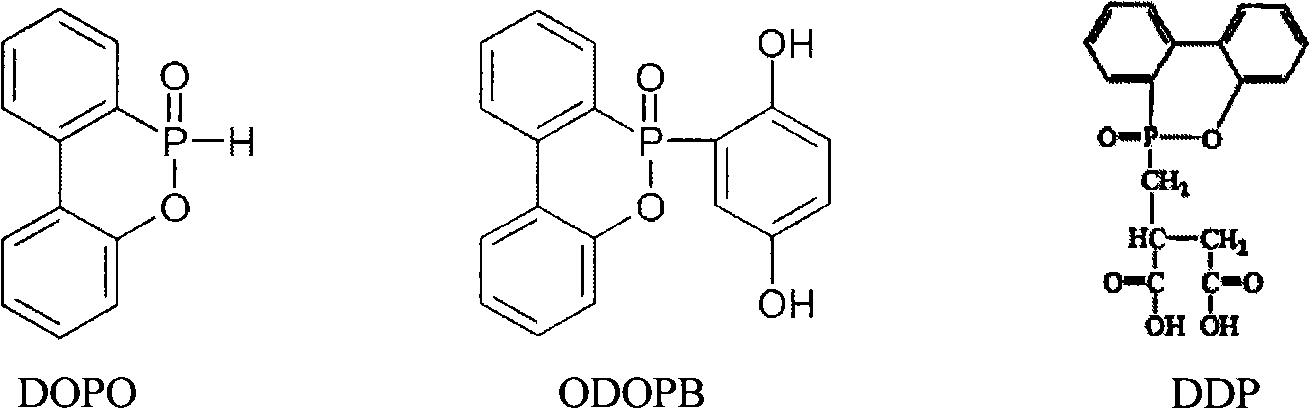

Method used

Image

Examples

Embodiment 1

[0075] Embodiment 1: prepare epoxy powder composition according to following material and ratio thereof:

[0076] Epoxy resin E12 22.75 parts by weight

[0077] Phosphorus-containing epoxy resin A 27.75 parts by weight

[0078] 4.63 parts by weight of phthalic anhydride

[0079] Imidazole 0.10 parts by weight

[0080] Silica powder 35.43 parts by weight

[0081] 9.10 parts by weight of melamine cyanuric acid (MCA)

[0082] Phthalocyanine blue 0.24 parts by weight

[0083] The above-mentioned substances are accurately weighed and added to a small high-speed mixing equipment. After being fully mixed, they are melted and extruded using a twin-screw extruder. The extruded melt is cooled and pressed into tablets, crushed, passed through a 100-mesh screen, and the upper layer of coarse material is discarded to obtain a flame-retardant phosphorus-containing epoxy powder composition. Then, the obtained epoxy powder can be tested for performance. The sample bar of a certain size...

Embodiment 2

[0085] Embodiment 2: prepare epoxy powder composition according to following material and ratio thereof:

[0086] Phosphorus-containing epoxy resin A 47.73 parts by weight

[0087] 6.25 parts by weight of phthalic anhydride

[0088] Imidazole 0.15 parts by weight

[0089] Silica powder 45.68 parts by weight

[0090] Phthalocyanine blue 0.19 parts by weight

[0091] The above materials were mixed and processed according to the operation mode of Example 1 to obtain a flame-retardant phosphorus-containing epoxy powder composition.

[0092] The measured horizontal flow rate of the flame-retardant phosphorus-containing epoxy powder composition is 28%, the gelation time is 53s, and the flame-retardant grade evaluated by the UL94 flame-retardant test is V0 grade.

Embodiment 3、4

[0093] Embodiment 3,4: prepare epoxy powder composition according to following material and ratio thereof:

[0094] Table 1

[0095] Example 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com