Process for producing gardening base material by mixing fermentation of corn stalk powder and peanut shell powder

A technology of peanut shell powder and corn stalk powder, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of long fermentation time, uneven fermentation temperature, time-consuming and labor-intensive, etc., to reduce EC value, The effect of shortening the fermentation time and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Mixture

[0019] The raw material of corn stalk powder is corn stalks above the ground after harvesting, crushed and sieved, with a particle size of 15 mm. After testing, this corn stalk powder contains 47.8% carbon, 0.5% nitrogen, and 13.2% water. Peanut shell powder is crushed and sieved peanut shells, with a particle size of 15mm. After testing, the peanut shell powder contains 50.2% carbon, 0.6% nitrogen and 10.0% water. Fermented nitrogen source urea contains 46.2% nitrogen, 20% carbon, and 0.5% water; fermented nitrogen source, dried chicken manure contains 2.4% nitrogen, 32.6% carbon, and 8.5% water.

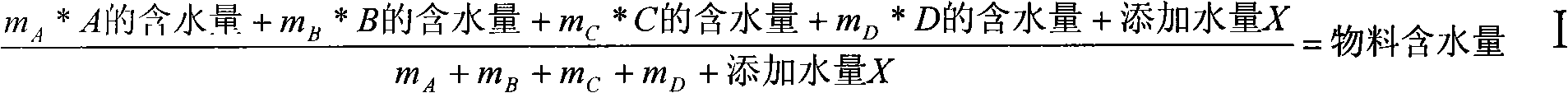

[0020] Each material is prepared according to the ratio of 80 parts by weight of corn stalk powder; 20 parts by weight of peanut shell powder; urea; and 0.36 parts by weight of dried chicken manure. , calculate and need to add 120 parts by weight of water by calculation formula following I.

[0021]

[0022] In the formula, use A to represent corn straw pow...

Embodiment 2

[0033] 1. Mixture

[0034] The raw material of corn stalk powder is corn stalks above the ground after harvesting, crushed and sieved, with a particle size of 15 mm. After testing, this corn stalk powder contains 46.2% carbon, 0.52% nitrogen, and 14.2% water. Peanut shell powder is crushed and sieved peanut shells, with a particle size of 15 mm. After testing, the peanut shell powder contains 51.2% carbon, 0.62% nitrogen, and 11.0% water. Fermented nitrogen source urea contains 46.2% nitrogen, 20% carbon, and 0.5% water; fermented nitrogen source, dried chicken manure contains 2.4% nitrogen, 32.6% carbon, and 8.7% water.

[0035] Each material is prepared according to the ratio of 50 parts by weight of corn stalk powder; 45 parts by weight of peanut shells; 1.14 parts by weight of urea; and 0.45 parts by weight of dried chicken manure. This feedstock has a carbon to nitrogen ratio of 45:1. According to the water content of the initial fermented material being 62%, it is calc...

Embodiment 3

[0047] 1. Mixture

[0048]The raw material of corn stalk powder is corn stalks above the ground after harvesting, crushed and sieved, with a particle size of 2 mm. After testing, this corn stalk powder contains 46.8% carbon, 0.56% nitrogen, and 14.9% water. Peanut shell powder is crushed and sieved peanut shells, with a particle size of 10mm. After testing, the peanut shell powder contains 51.6% carbon, 0.66% nitrogen and 11.2% water. Fermented nitrogen source urea contains 46.2% nitrogen, 20% carbon, and 0.51% water; fermented nitrogen source, dried chicken manure contains 2.4% nitrogen, 32.66% carbon, and 9.7% water.

[0049] Each material is prepared according to the ratio of 65 parts by weight of corn stalk powder; 35 parts by weight of peanut shell; 1.0 part by weight of urea; and 0.56 part by weight of dried chicken manure. The carbon-to-nitrogen ratio of this material is 46: 1, according to the water content of the initial fermentation material 64%, calculated by the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com