Special membrane and method for manufacturing radio-frequency label antenna

A technology of radio frequency tags and thin films, applied in chemical/electrolytic methods to remove conductive materials, chemical instruments and methods, structural forms of radiation elements, etc., can solve the problems of adding, increasing operation difficulty, reducing processing speed, etc., to achieve the realization of technology Breakthrough, reduce production cost and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

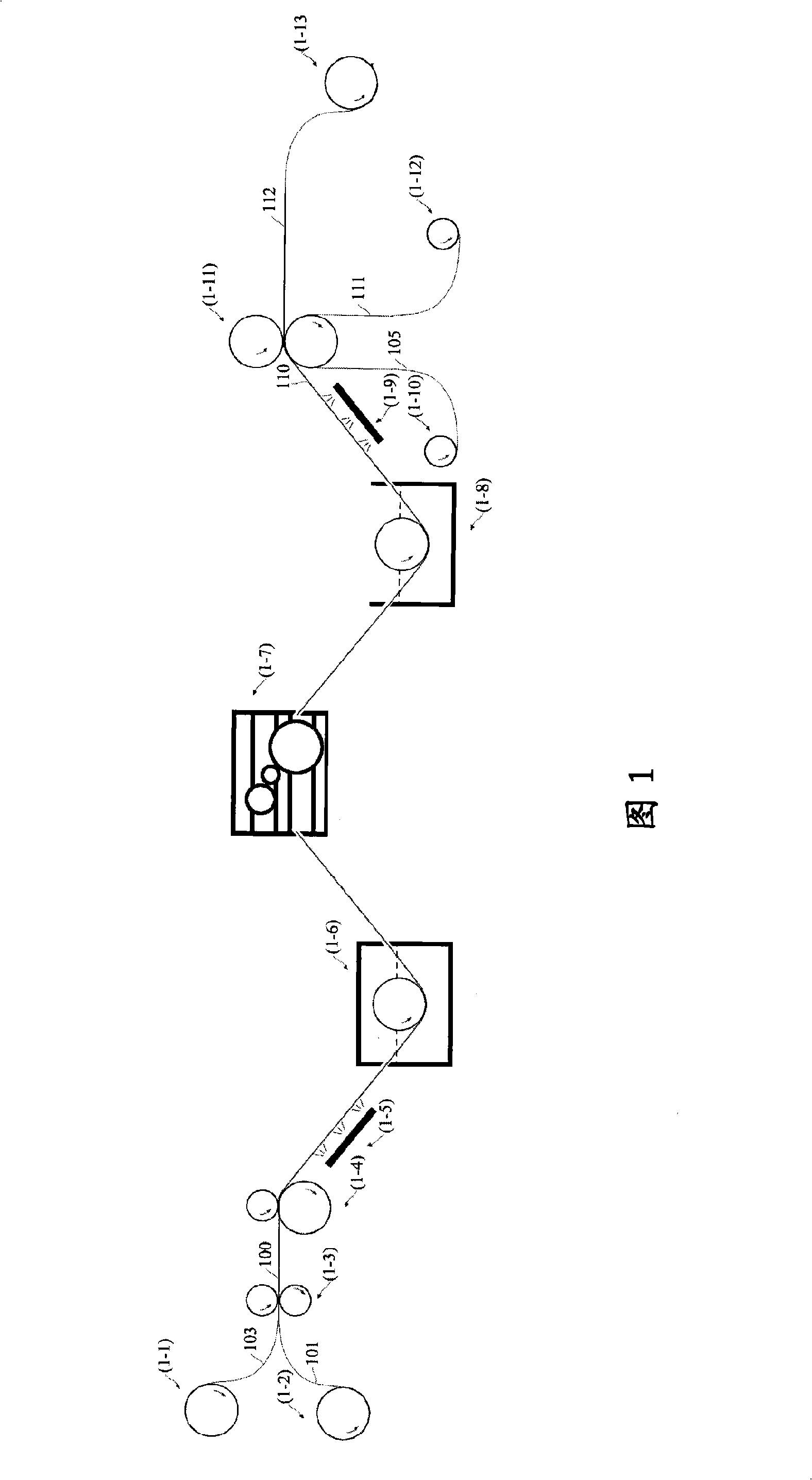

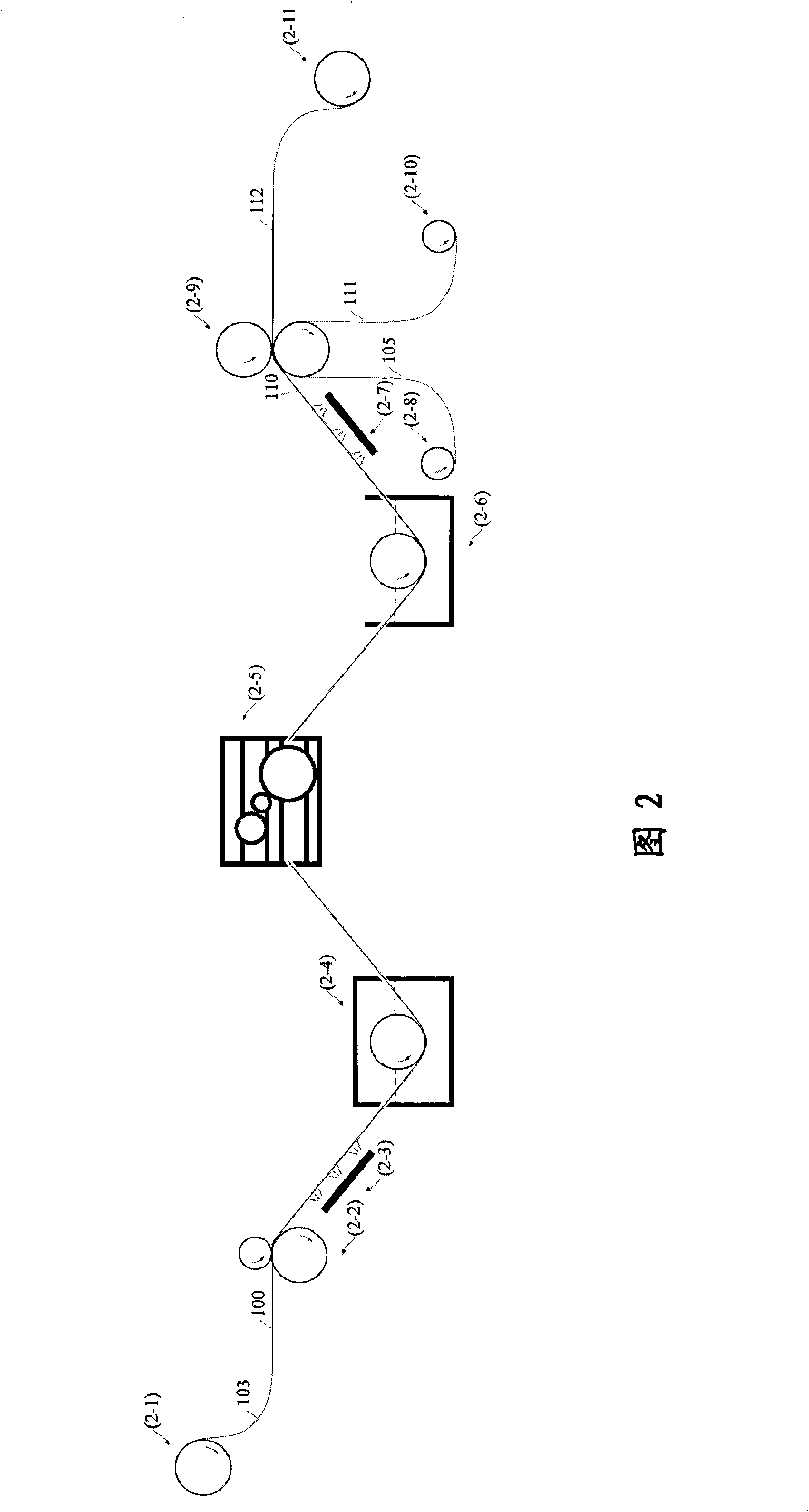

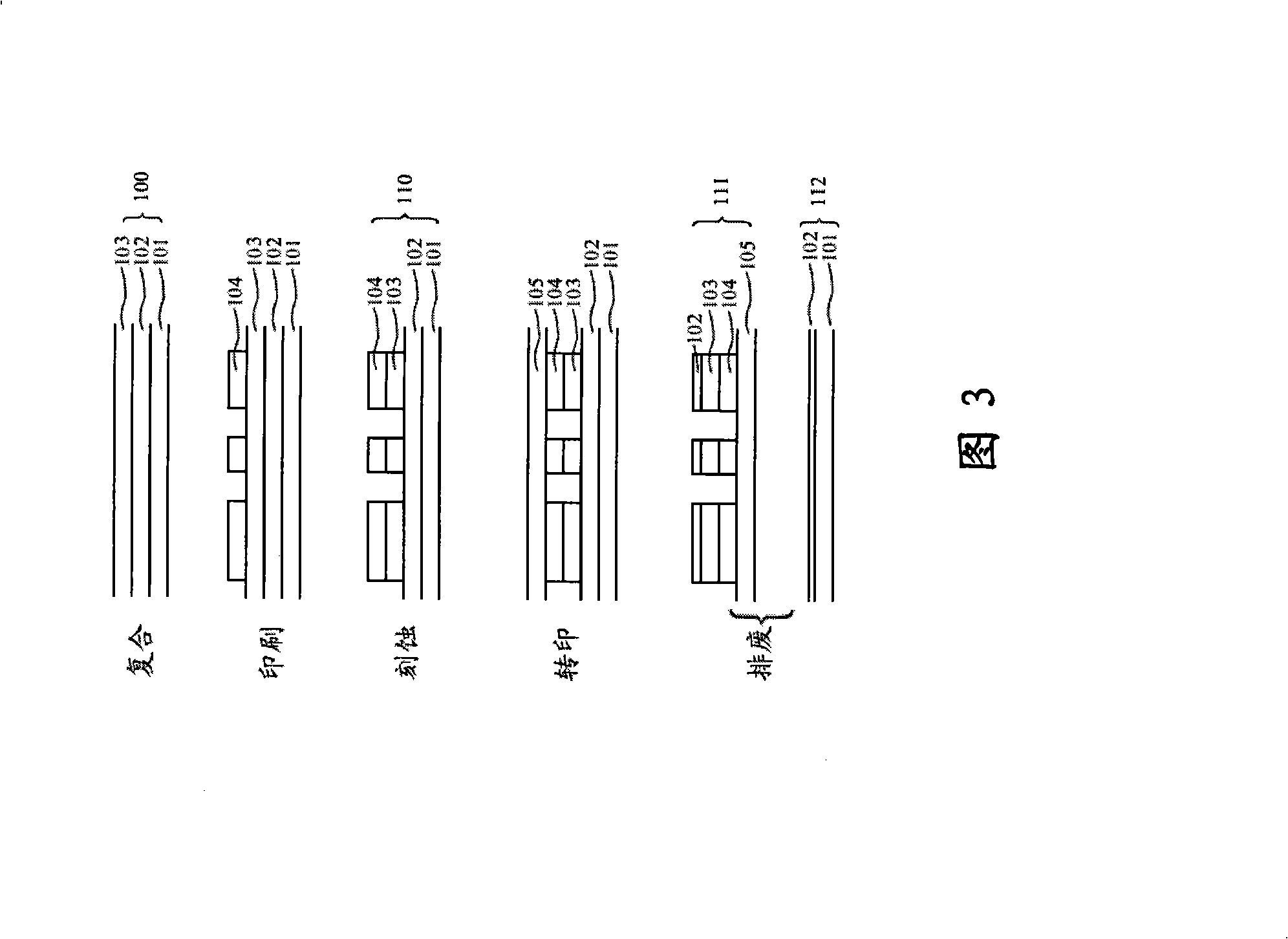

[0055] What the present invention is to solve is how to print high-precision, thick metal film layer, and low-impedance RFID antenna on a special film by using printing, etching and transfer processes, while simplifying the process, increasing the yield, and reducing the cost.

[0056] The invention relates to a special film for making radio frequency tag antenna, the structure includes:

[0057] a basement membrane layer;

[0058] A release material layer formed on the base film layer; and

[0059] A metal layer is formed on the release material layer.

[0060] The production process of the special film adopts vacuum plating or compounding of metal foil and plastic film. When using the vacuum plating process, first coat the release material layer on the base film layer, dry it, and then place it in a vacuum chamber to coat a metal film with a suitable thickness. When the compounding process is adopted, dry compounding can be selected, first coat the release material layer on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com