Swinging type wave energy fluid metal magnetohydrodynamic electricity generation float tube

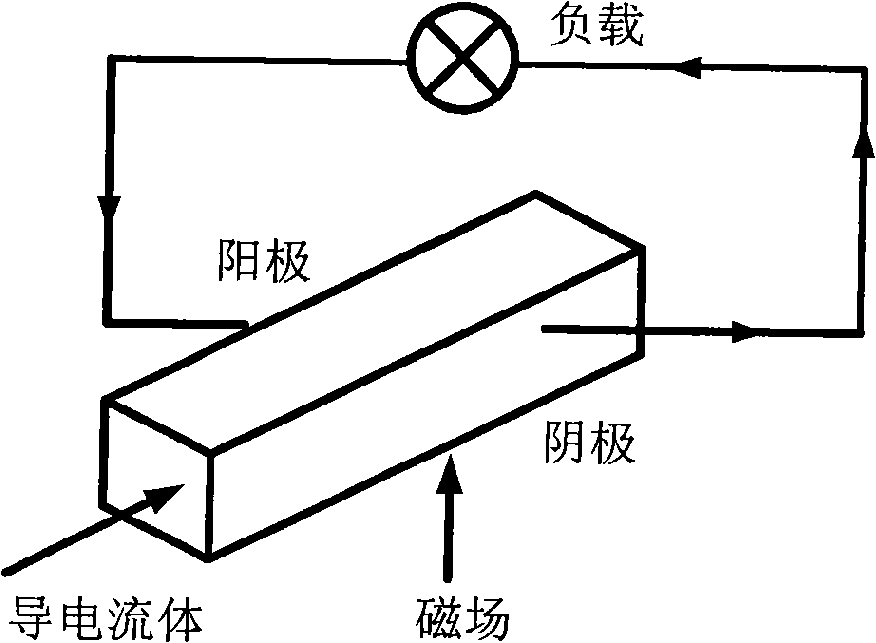

A magnetic fluid power generation and liquid metal technology, applied in electrical components, electromechanical devices, etc., can solve the problems of poor wind and wave shock resistance, generator loss, large generator and other problems, and achieve reduced mechanical loss, high power density, and high conversion. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

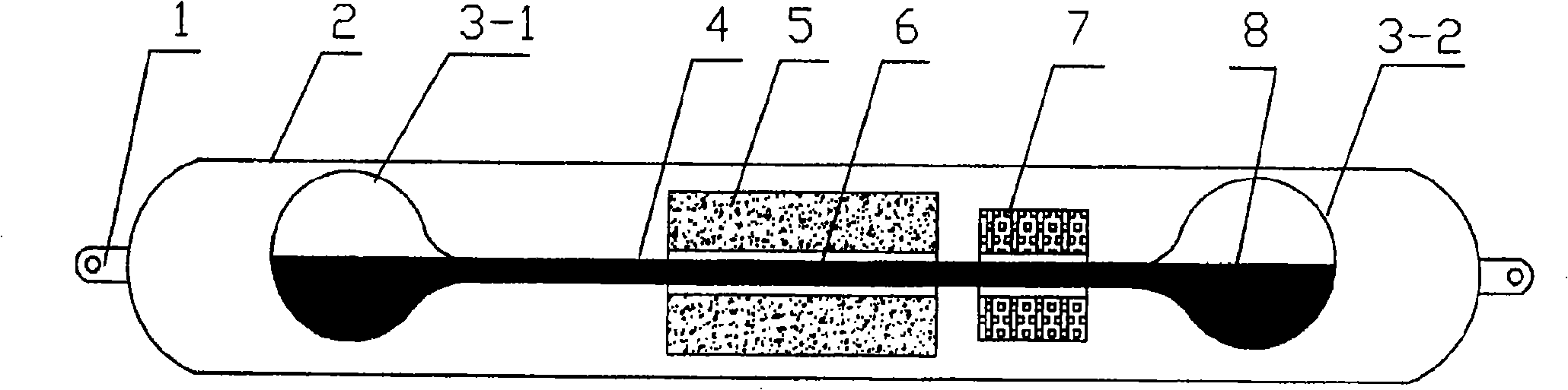

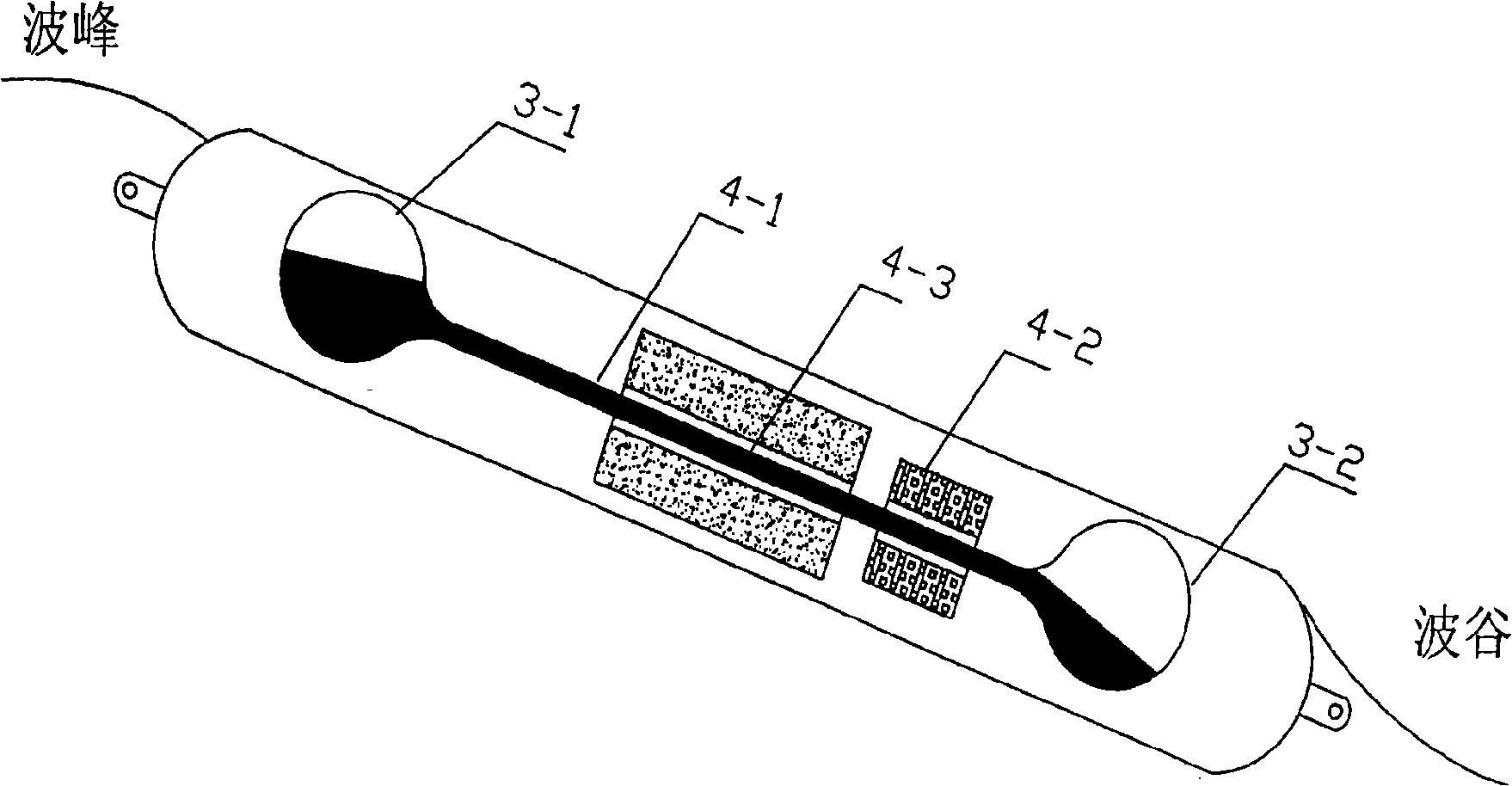

[0020] figure 2 It is a structural schematic diagram of a specific embodiment of the present invention. like figure 2As shown, the specific embodiment of the present invention consists of a shackle 1, a floating tube housing 2, a left storage container 3-1 and a right storage container 3-2, a power generation channel 4, a magnet 5, an electrode 6, a power output system 7, Liquid metal 8 and other components. The floating tube shell 2 is a tube with both ends sealed, and the left storage container 3-1 and the right storage container 3-2, the power generation channel 4, the magnet 5, the electrode 6, and the power output system 7 are arranged in the floating tube shell 2 Inside. The magnet 5 is placed in the middle section of the floating tube shell 2, and is a bipolar magnet, which can be a permanent magnet or an electromagnet, or a superc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com