Multi-layer printed circuit board, design method thereof, and final product of mainboard

A technology of multi-layer printing and design method, which is applied in the direction of multi-layer circuit manufacturing, printed circuit components, printed circuits connected with non-printed electrical components, etc. and other problems, to achieve the effect of improving interconnection density and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiment of the present invention aims to provide a design method for a multilayer printed circuit board, a main board of an end product, and a multilayer printed circuit board that can save the space occupied by via holes and increase the interconnection density. Detailed description.

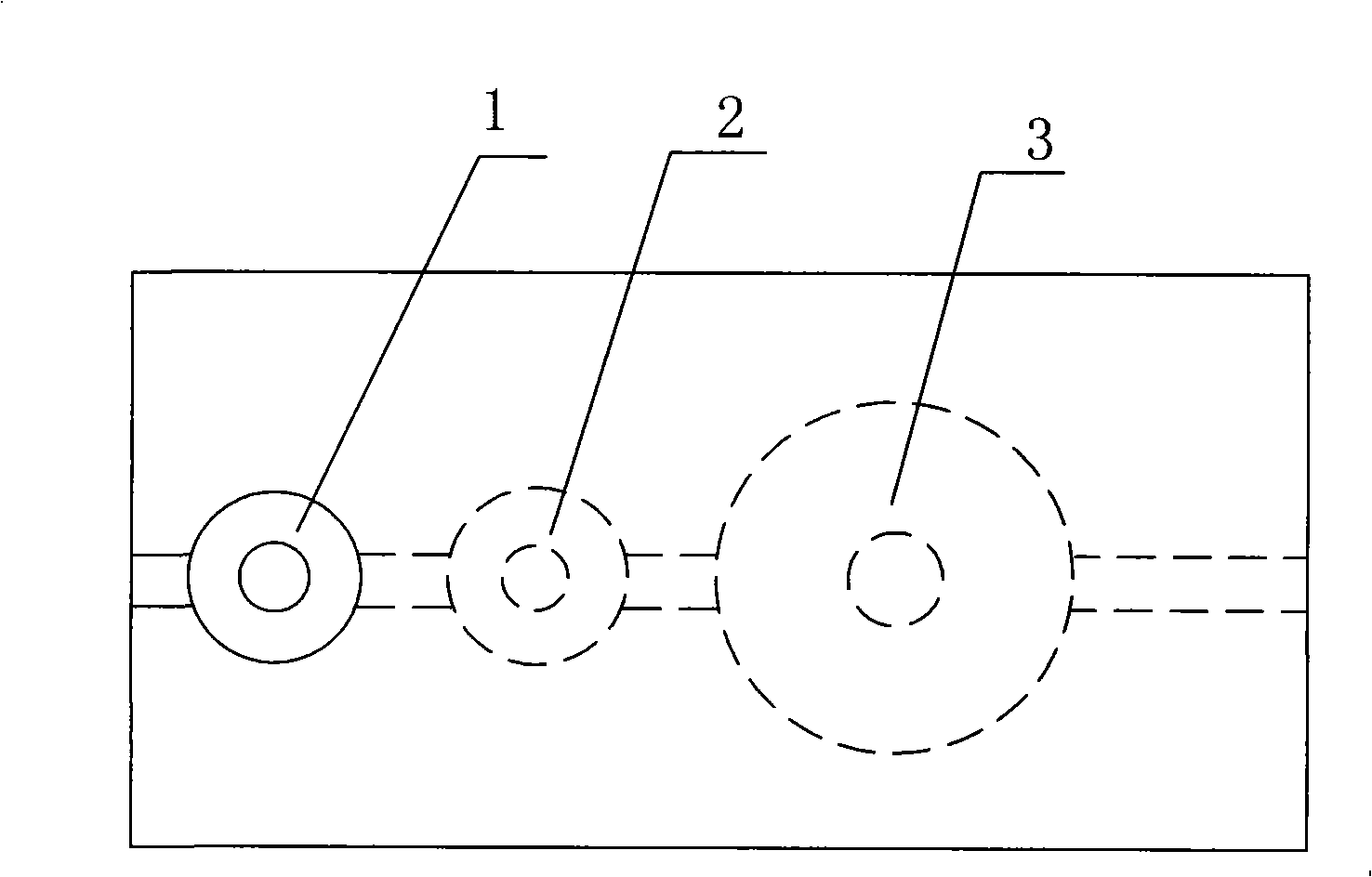

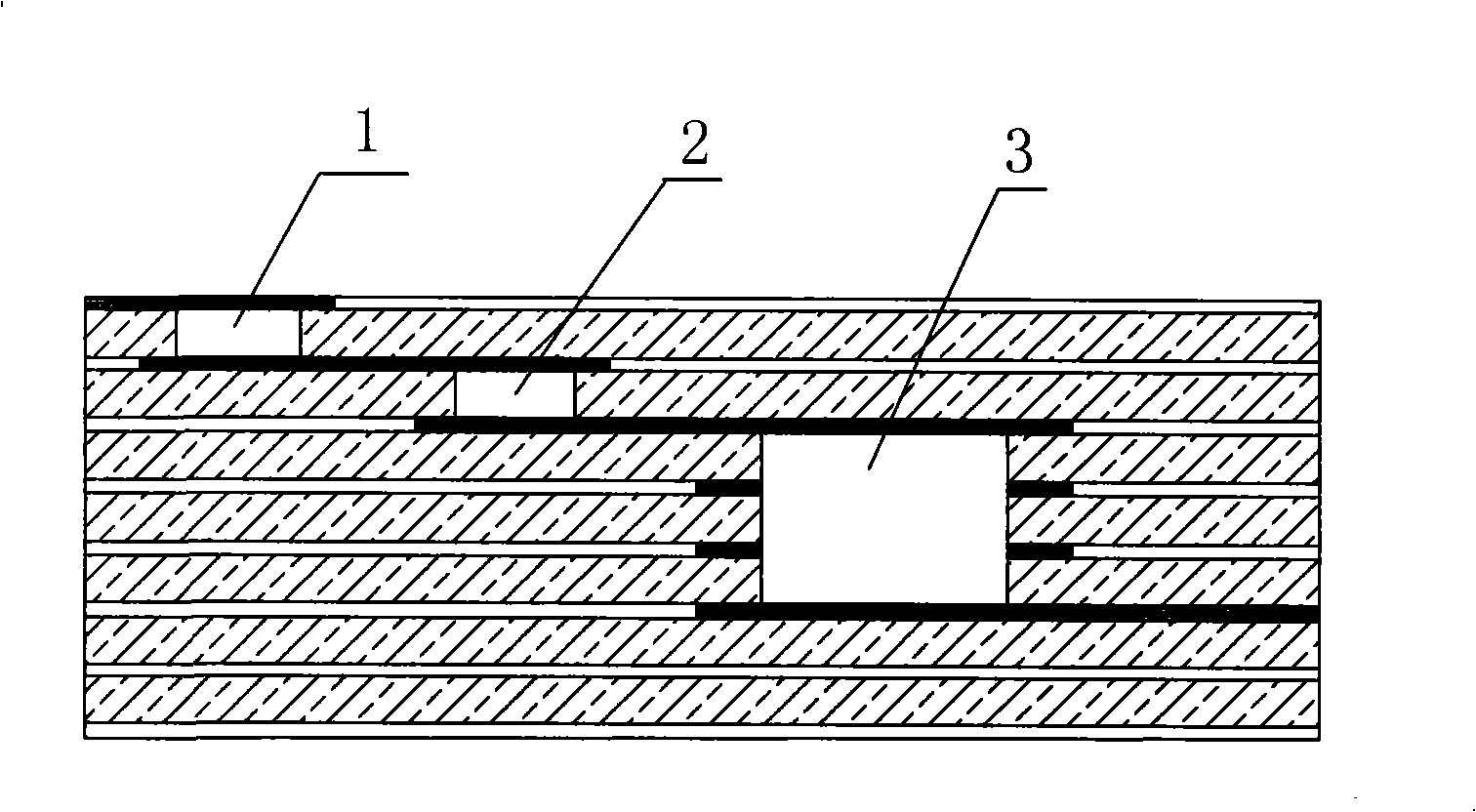

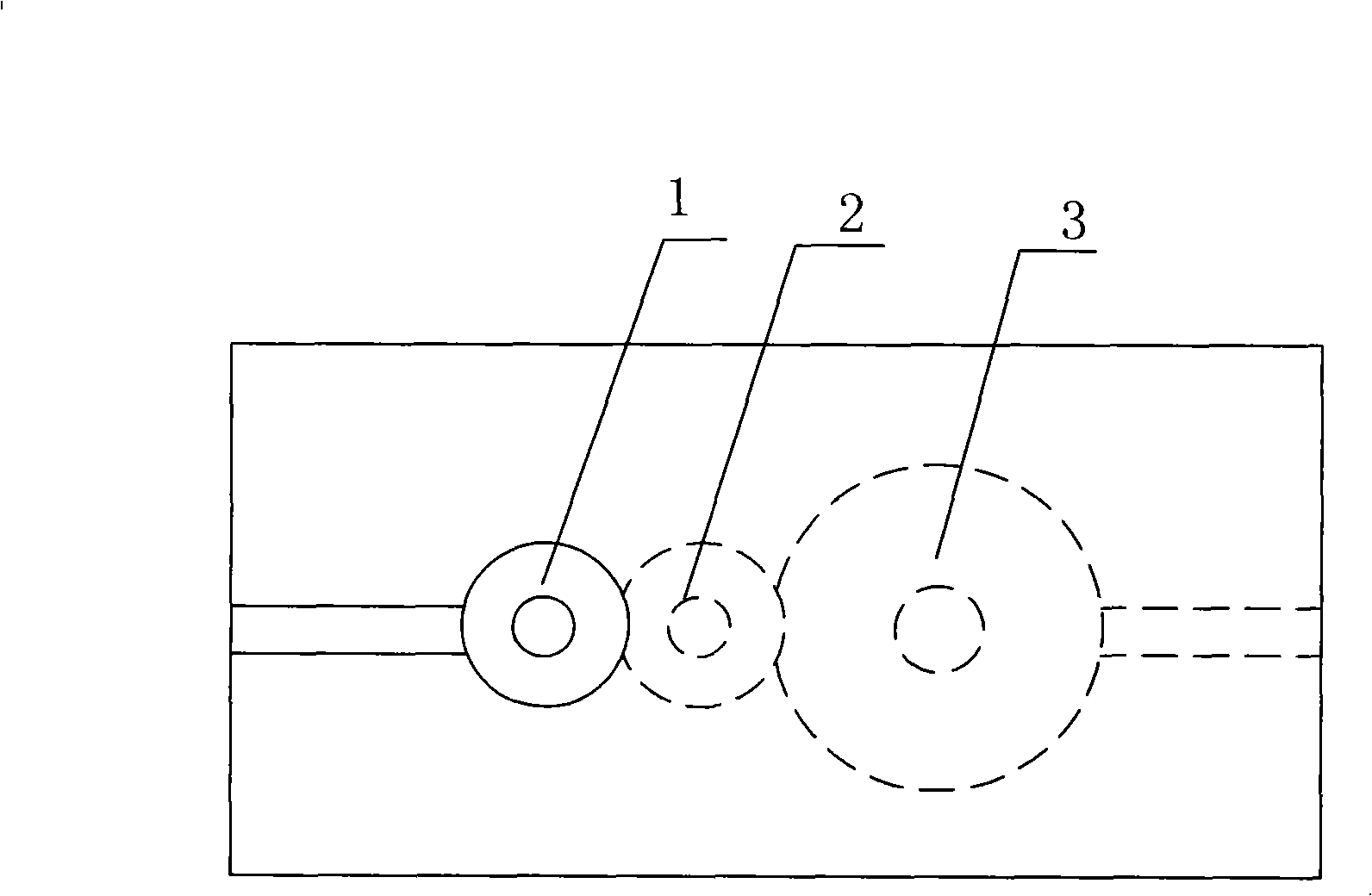

[0039] refer to image 3 , Figure 4 As shown, the multilayer printed circuit board of the embodiment of the present invention includes a substrate 100, on which a conductor circuit layer 101 and an interlayer insulating layer 102 are repeatedly formed in an alternating manner on the substrate 100; the conductor in this embodiment The circuit layer 101 has eight layers, and the interlayer insulating layer 102 has seven layers. In the interlayer insulating layer 102, a signal connection via hole is provided. The signal connection via hole in this embodiment includes a microhole 1 from the first layer to the second layer, and a microhole from the second layer to the third layer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com