Method for treating a gas containing nitrogen oxides (NOx), using as nox trap a composition based on zirconium oxide and praseodymium oxide

A technology of nitrogen oxides and zirconium oxides, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

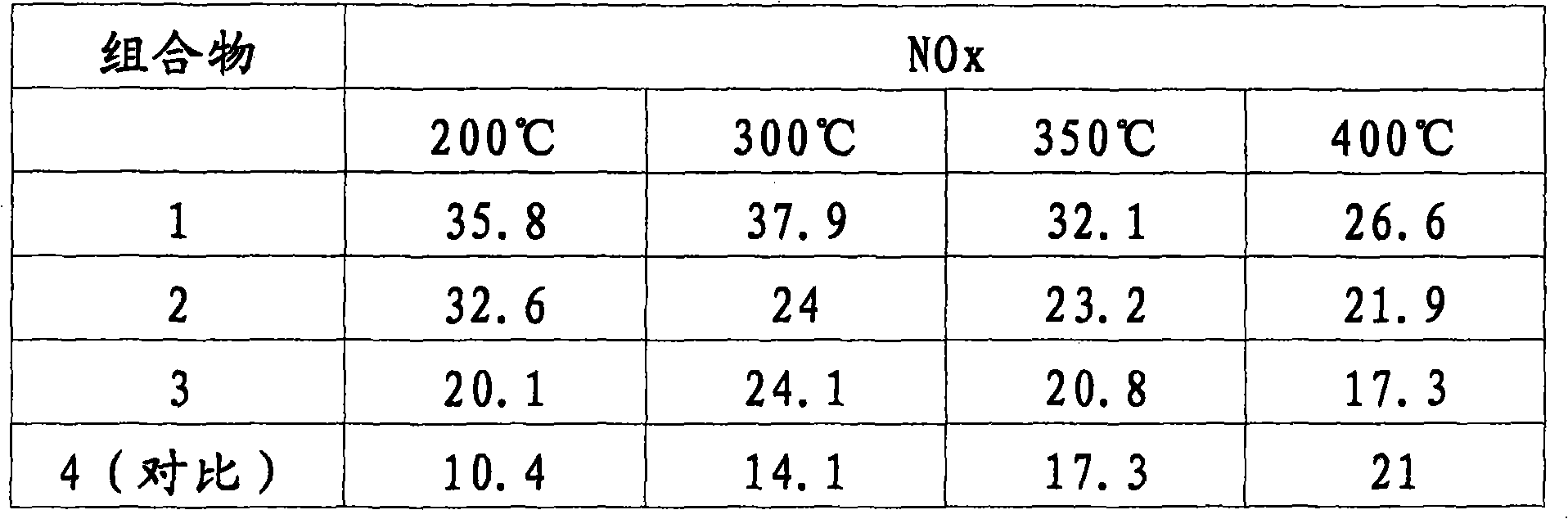

Examples

Embodiment 1

[0067] This example concerns the preparation of a first compound that can be incorporated into a composition that can be used in the methods of the invention. This compound is based on oxides of cerium, zirconium and praseodymium, expressed in proportions by mass of oxides of 55%, 15% and 30% respectively.

[0068] The ceric nitrate solution, the praseodymium nitrate solution and the zirconium nitrate solution are mixed in the stoichiometric ratios required to obtain the above mixed oxides. This zirconium solution is obtained by etching zirconium carbonate with concentrated nitric acid. Such a solution is such that the amount of base required to reach the equivalence point during an acid / base titration of this solution obeys the condition OH - / Zr molar ratio = 1.14.

[0069] Acid / base titrations are performed in a known manner. To make it work under optimal conditions, the concentration expressed in elemental zirconium can be titrated to approximately 3x10 -2 mol / liter so...

Embodiment 2

[0073] This example concerns the preparation of a second compound that can be incorporated into a composition that can be used in the method of the invention. This compound is based on 60% zirconium and 40% praseodymium, these proportions are based on the oxide ZrO 2 and Pr 6 o 11 expressed as a mass percentage.

[0074] 500 ml of zirconium nitrate (120 g / l) and 80 ml of praseodymium nitrate (500 g / l) were introduced into the stirring beaker. It was subsequently replenished with distilled water to obtain 1 liter of nitrate solution.

[0075]224 ml of an aqueous ammonia solution (12 mol / l) were introduced into the stirred reactor and subsequently replenished with distilled water to obtain a total volume of 1 liter.

[0076] The nitrate solution was introduced into the continuously stirred reactor over 1 hour.

[0077] The obtained solution was placed in a stainless steel autoclave equipped with a stirrer. The temperature of the medium is brought to 150° C. under stirring ...

Embodiment 3

[0084] This example concerns the preparation of a third compound that can be incorporated into compositions that can be used in the methods of the invention. This compound is based on 90% zirconium and 10% praseodymium, these proportions are based on the oxide ZrO 2 and Pr 6 o 11 expressed as a mass percentage.

[0085] The operating steps were carried out in the same manner as in Example 2, and the nitrate solution was mixed to obtain the stoichiometric ratio required for the above-mentioned mixed oxide. The specific surface area after calcination is 70m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com