Rice direct seeding fields herbicidal compositions

A technology of herbicides and compositions, applied in the direction of herbicides, algicides, biocides, biocides, etc., which can solve the problem of difficulty in using methods, operations, and dosage, high cost of cyhalofop-ethyl, and inability to control weeds and other problems, to achieve the effect of broad development and application prospects and development space, good weeding effect and outstanding social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

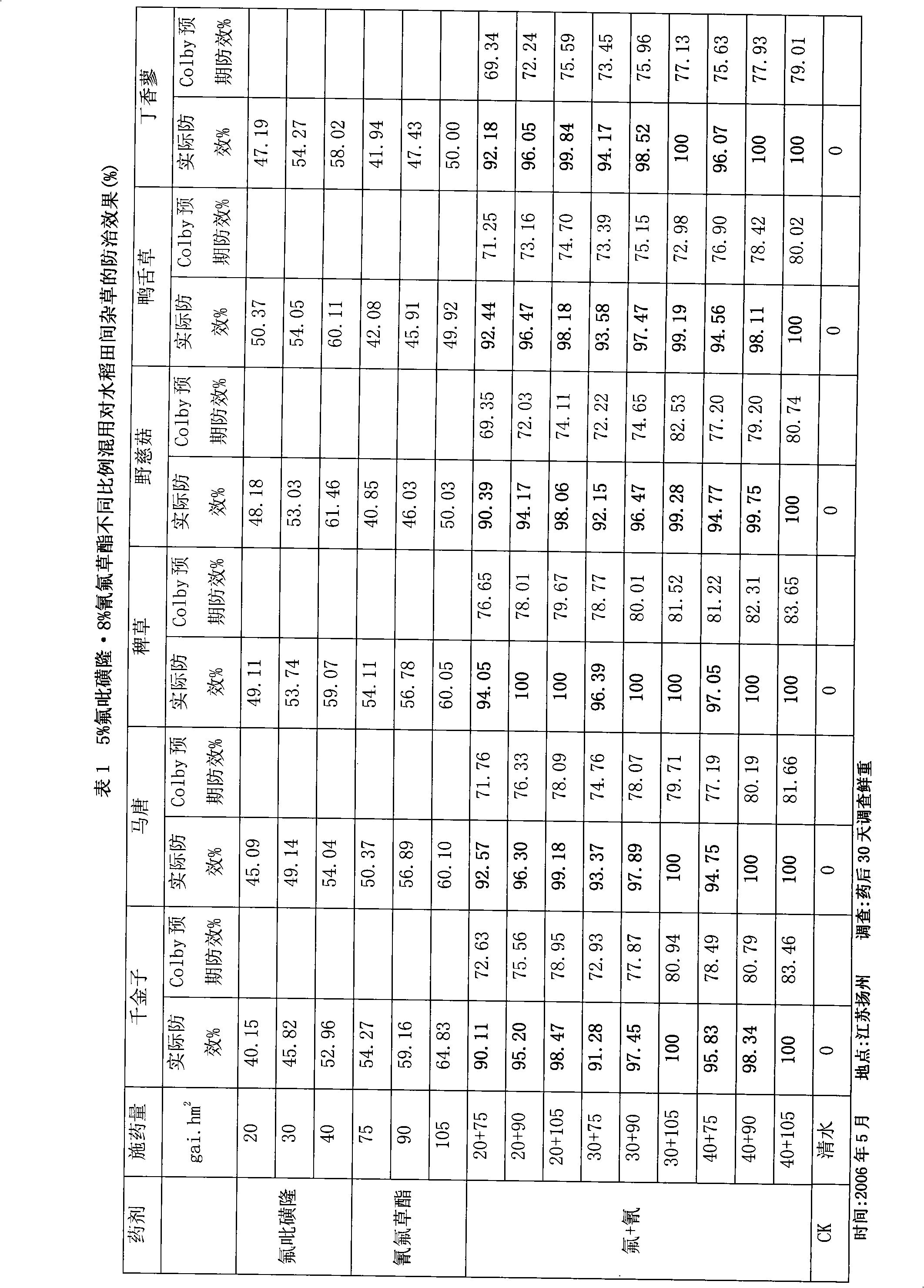

Examples

Embodiment 1

[0028] Put 2kg of flubisulfuron-methyl technical, 2kg of cyhalofop-methyl, 12kg of methanol, 66kg of xylene into the reaction kettle, mix and stir evenly, then add 8kg of phenylethylphenol polyoxyethylene ether, 10kg of dodecyl Calcium benzenesulfonate, mixed and stirred evenly for 2 hours, prepared emulsifiable concentrate preparation.

Embodiment 2

[0030]2kg flubisulfuron-methyl, 5kg cyhalofop-methyl and 6kg sodium dodecylbenzenesulfonate, 10kg sodium lignosulfonate, 2kg polyvinyl alcohol, 2kg lauryl polyoxyethylene ether, 35kg kaolin, 38kg bentonite, Add them together to the cone mixer and mix for more than 2 hours, then put the mixed material into the jet mill for crushing, then add the crushed material into the cone mixer and mix for 2 hours, the fineness of the mixed material reaches 98% passed through a 325-mesh standard sieve to obtain a wettable powder. Then put the wettable powder and 20kg of purified water into the kneader and knead at the same time to make a plastic material, and finally put the material into an extrusion granulator for granulation, and the granulated product is processed in an oven at 54 ° C. Drying, sieving the dried material with standard sieves of 10 mesh and 60 mesh, and taking the material between the two sieves to obtain water-dispersible granules.

Embodiment 3

[0032] 2kg flubisulfuron-methyl, 10kg cyhalofop-methyl and 5kg sodium dodecylbenzenesulfonate, 9kg sodium lignosulfonate, 4kg polyvinyl alcohol, 3kg lauryl polyoxyethylene ether, 35kg kaolin, 32kg bentonite, Add them together to the cone mixer and mix for more than 2 hours, then put the mixed material into the jet mill for crushing, then add the crushed material into the cone mixer and mix for 2 hours, the fineness of the mixed material reaches 98% passed through a 325-mesh standard sieve to obtain a wettable powder. Then put the wettable powder and 20kg of purified water into the kneader and knead at the same time to make a plastic material, and finally put the material into an extrusion granulator for granulation, and the granulated product is processed in an oven at 54 ° C. Drying, sieving the dried material with standard sieves of 10 mesh and 60 mesh, and taking the material between the two sieves to obtain water-dispersible granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com