Optical thin film with non-spherical particle

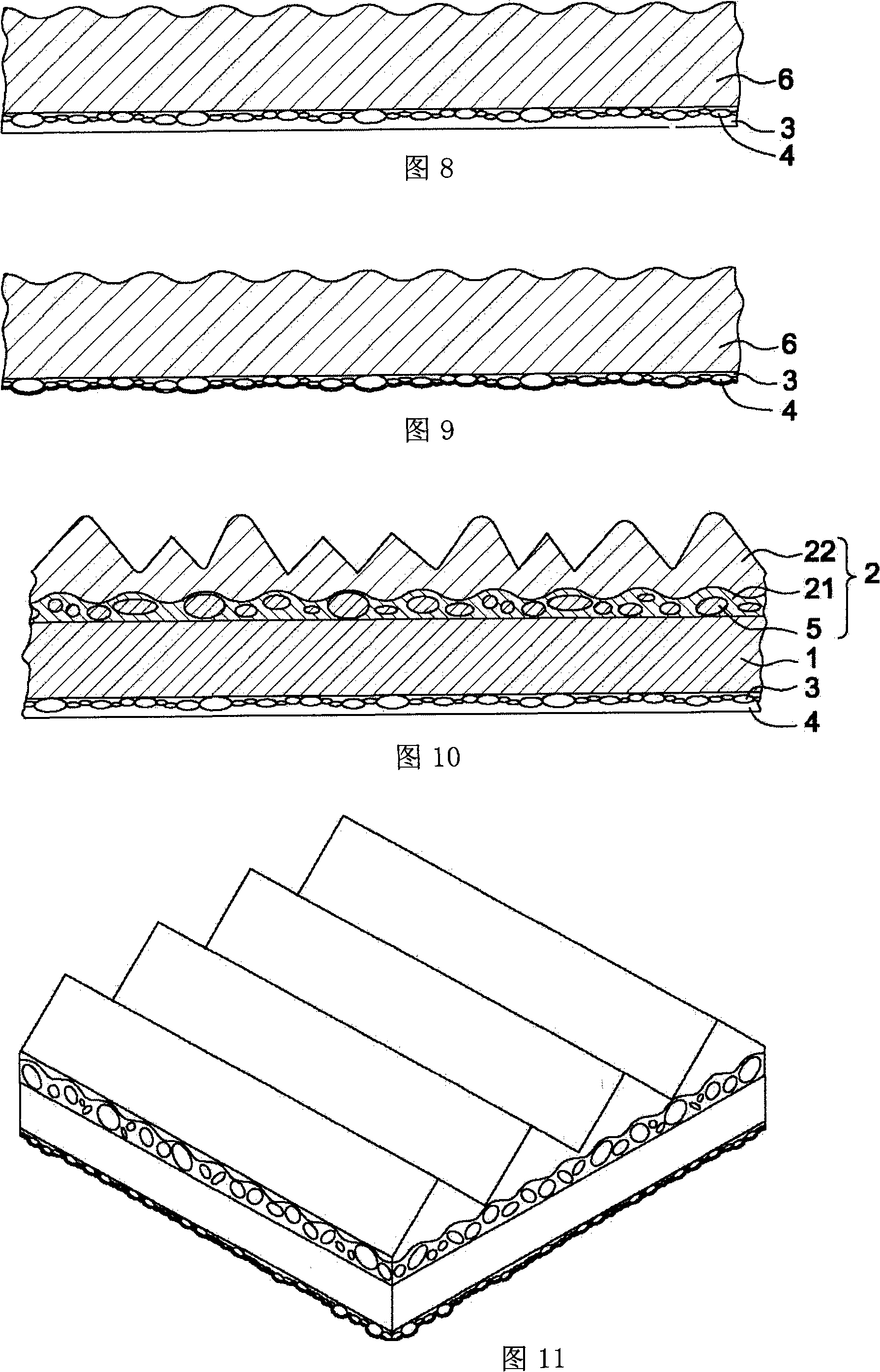

An optical film, aspherical technology, applied in the parts of lighting devices, lighting devices, refractors, etc., can solve the problems of easy aggregation or adhesion of spherical particles, reduced light penetration, decreased brightness, etc. The chemical effect will not be reduced, the light penetration will be improved, and the brightness will be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

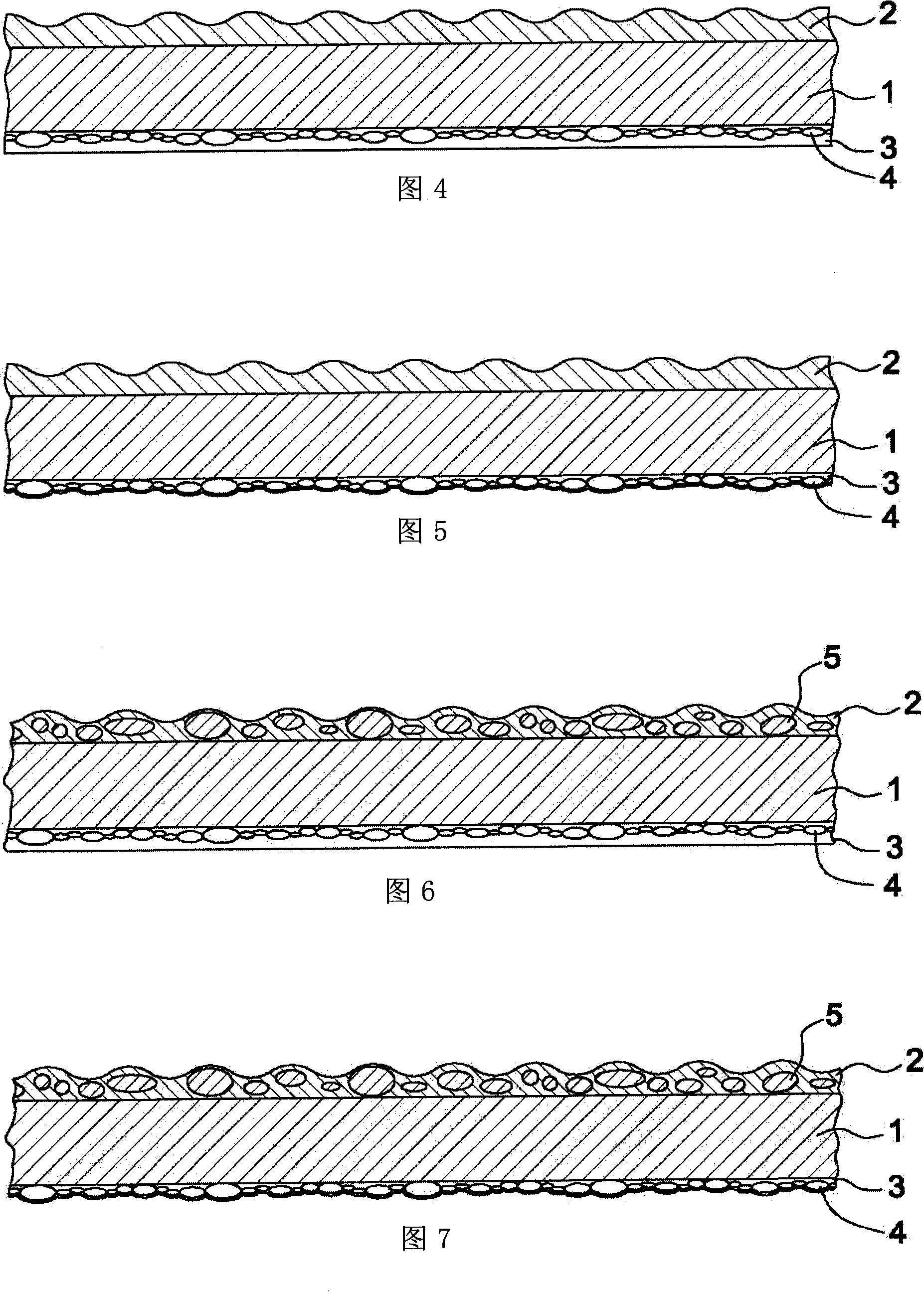

Embodiment 1

[0085] Use RDS applicator stick #5 to coat paint A on the surface of a transparent PET film [U34, Toray Company] with a thickness of 188μm. After drying at 80℃ for 1 minute, use a UV exposure machine [Fusion UV, F600V, 600W / inch, H-type light source], power is set to 100%, speed is 15m / min, energy beam is 200mJ / cm 2 , After drying to form a resin coating. The film thickness test was performed, and the total thickness obtained was about 190.2 μm.

Embodiment 2

[0087] Coating B was coated on the surface of a transparent PET film [U34, Toray Company] with a thickness of 188μm with RDS smear stick #5, and then dried and cured under the conditions of Example 1 to form a resin coating on the substrate. The film thickness test was performed, and the total thickness obtained was about 190.2 μm.

Embodiment 5

[0093] Use RDS applicator rod #5 to apply paint A on the diffuser with a thickness of 213μm [ DI-780A, Eternal Corporation], dried and cured under the conditions of Example 1 to form a resin coating on the substrate. The film thickness test was performed, and the total thickness obtained was about 215.2 μm.

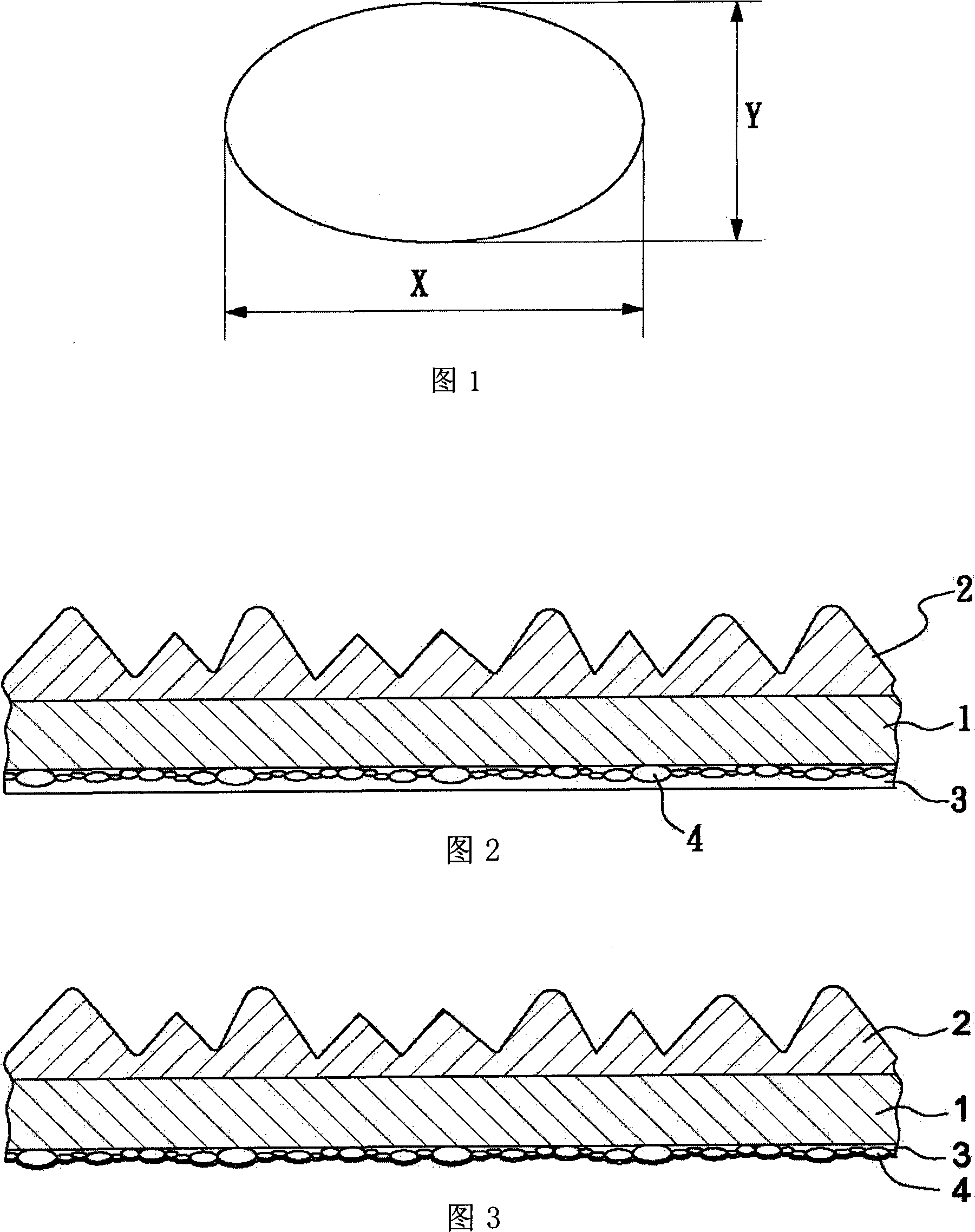

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com