Stretching type folding probe

A stretching and probe technology, applied in the field of probes, can solve problems such as unsatisfactory, too high needle height, limited performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

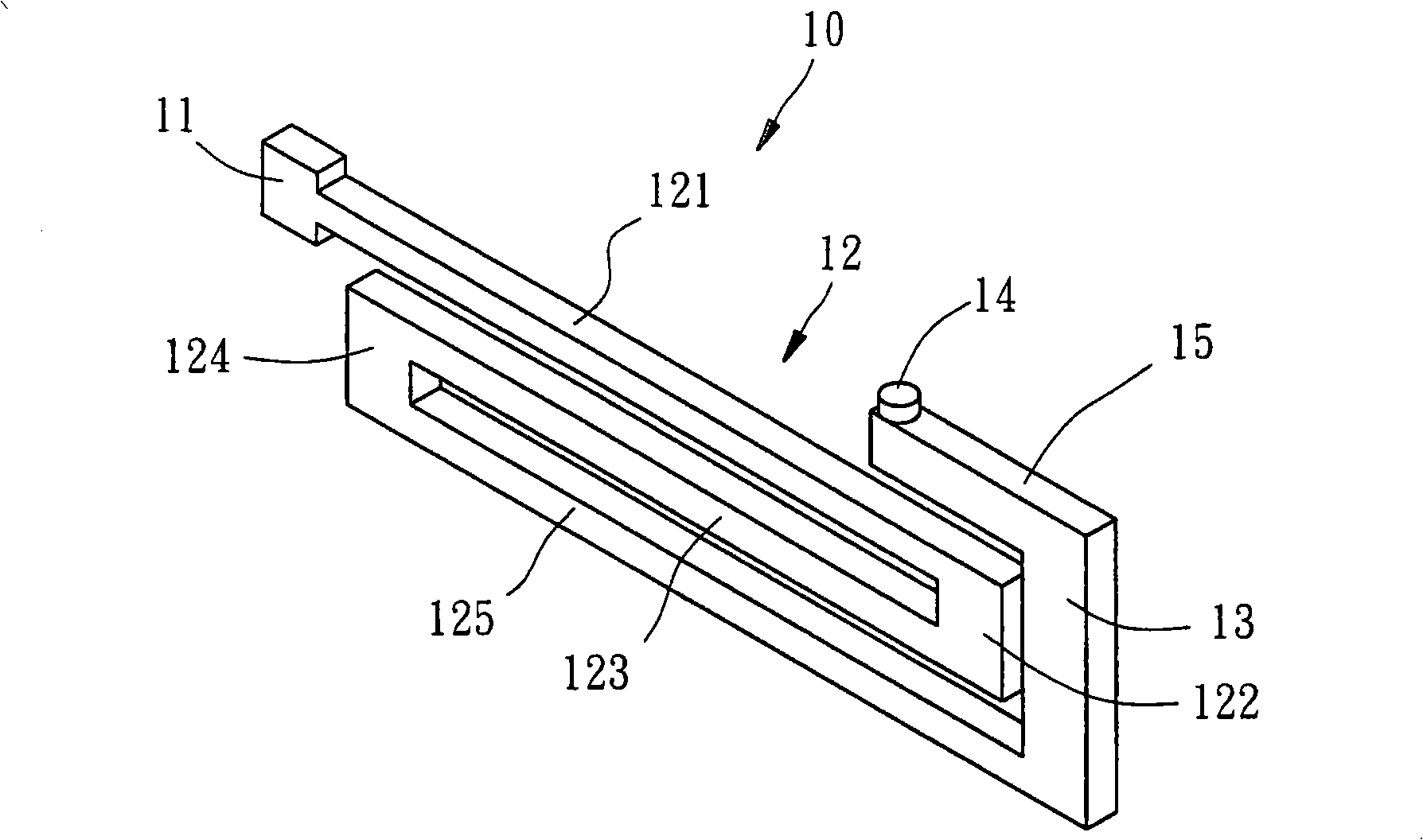

[0042] Please refer to image 3 , is a stretchable folded probe 10 provided by a preferred embodiment of the present invention, which includes a fixed part 11, a folded part 12 and a needle tip part 13 made integrally; the folded part 12 has a A first horizontal section 121 extending a predetermined distance horizontally on one side of the fixing portion 11, a first vertical section 122 extending a predetermined distance from the free end of the first horizontal section to the vertical direction, a free end from the first vertical section 122 A second horizontal segment 123 extending horizontally for a predetermined distance from the end toward the fixed portion 11, a second vertical segment 124 vertically extending a predetermined distance from the free end of the second horizontal segment 123 to the opposite direction of the fixed portion 11, and a The free end of the second vertical section 124 extends horizontally to the opposite side of the fixed part for a predetermined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com