Array type single-air chamber solid oxide fuel battery pack module

A solid oxide, fuel cell stack technology, used in solid electrolyte fuel cells, fuel cell grouping, fuel cells, etc., can solve the problem of low space utilization, inability to obtain output voltage and output power, and inability of battery packs to effectively amplify, etc. problem, to achieve the effect of simple and compact structure and flexible assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

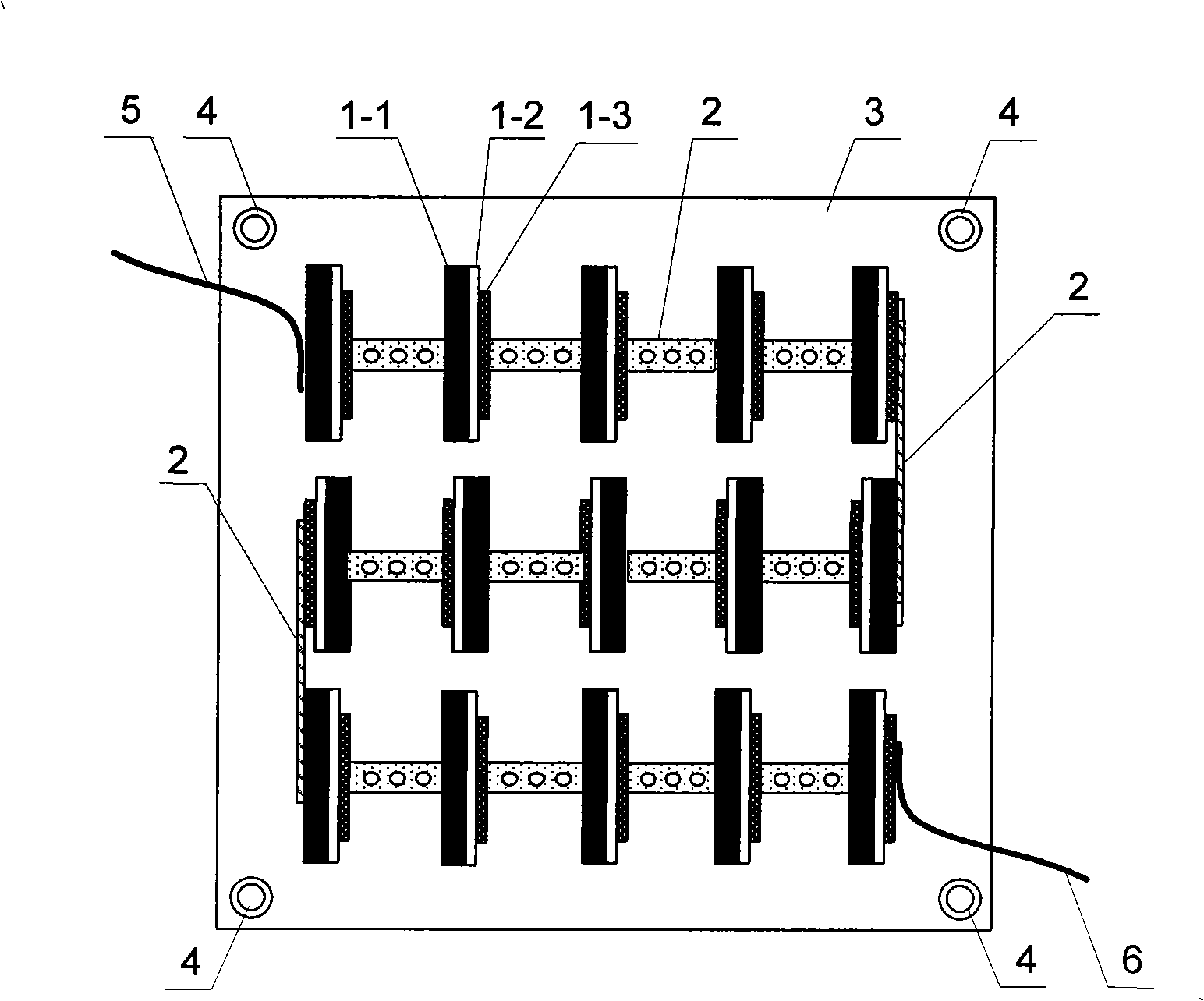

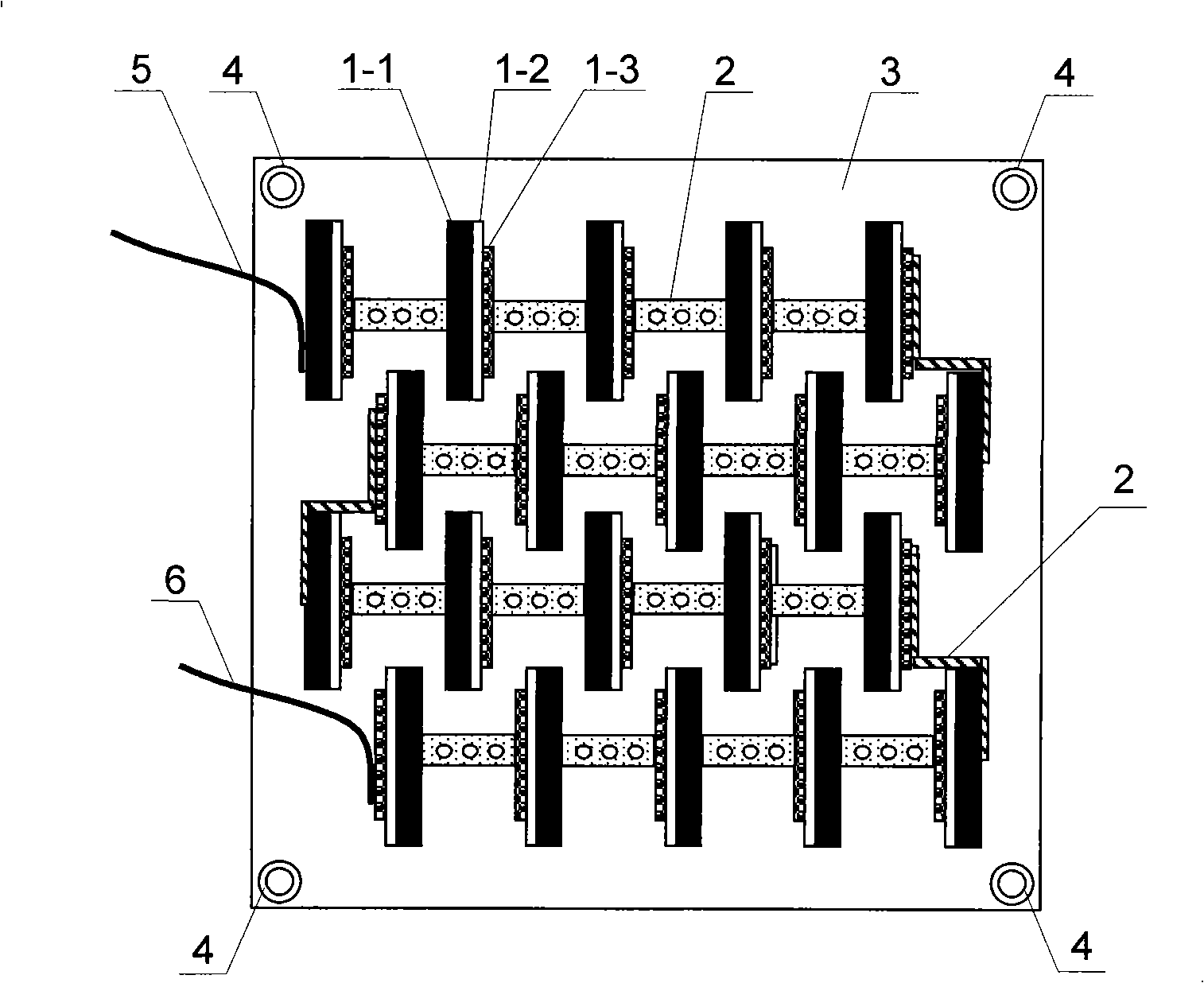

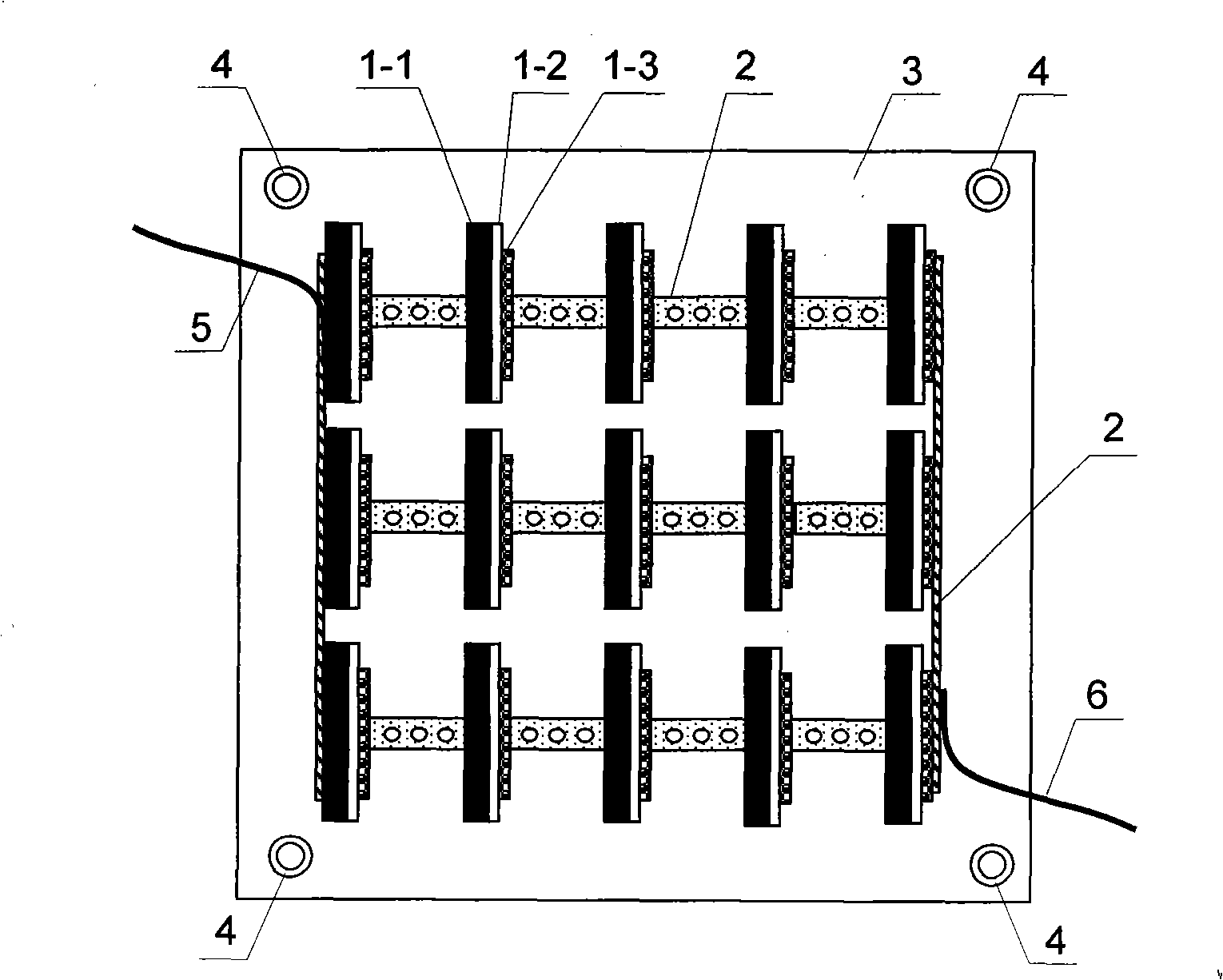

[0009] Specific implementation mode one: the following combination Figure 1 to Figure 11 Describe this embodiment, this embodiment is made up of a plurality of cells, a plurality of conductors 2, an insulating support plate 3, an anode current lead 5 and a cathode current lead 6, each cell consists of an anode 1-1, an electrolyte layer 1- 2 and a porous cathode 1-3, one side of the anode 1-1 is fixed with an electrolyte layer 1-2, the other side of the electrolyte layer 1-2 is coated with a porous cathode 1-3, and the insulating support plate 3 The upper surface is provided with a plurality of positioning grooves 3-1, and each single battery is placed in a positioning groove 3-1 respectively, and the single batteries are connected in series, parallel or series-parallel by conductors 2, and the battery pack module An anode current lead 5 and a cathode current lead 6 are provided.

[0010] figure 1 , figure 2 , Figure 5 ~ Figure 7 , Figure 9 and Figure 10 The number o...

specific Embodiment approach 2

[0014] Embodiment 2: The single cell is an anode-supported thin-film fuel cell, electrolyte-supported fuel cell or cathode-supported thin-film fuel cell, and the cross-sectional shape of the single cell is circular, trapezoidal or rectangular. Others are the same as Embodiment 1.

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the material of the conductor 2 is a high-temperature redox-resistant metal material, a conductive alloy or an oxide ceramic material; The spaced metal strips of rectangular or circular air holes, or metal wires, are the same as those of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap