Milk powder preparation with maintenance overhaul of nutrition

A production method and complete nutrition technology, applied in the preservation of milk, milk preparations, other dairy products, etc., can solve the problems of destroying the nutritional components of milk powder, poor appearance, etc., achieving economical processing costs, easy and simple sterilization, Processing simplification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

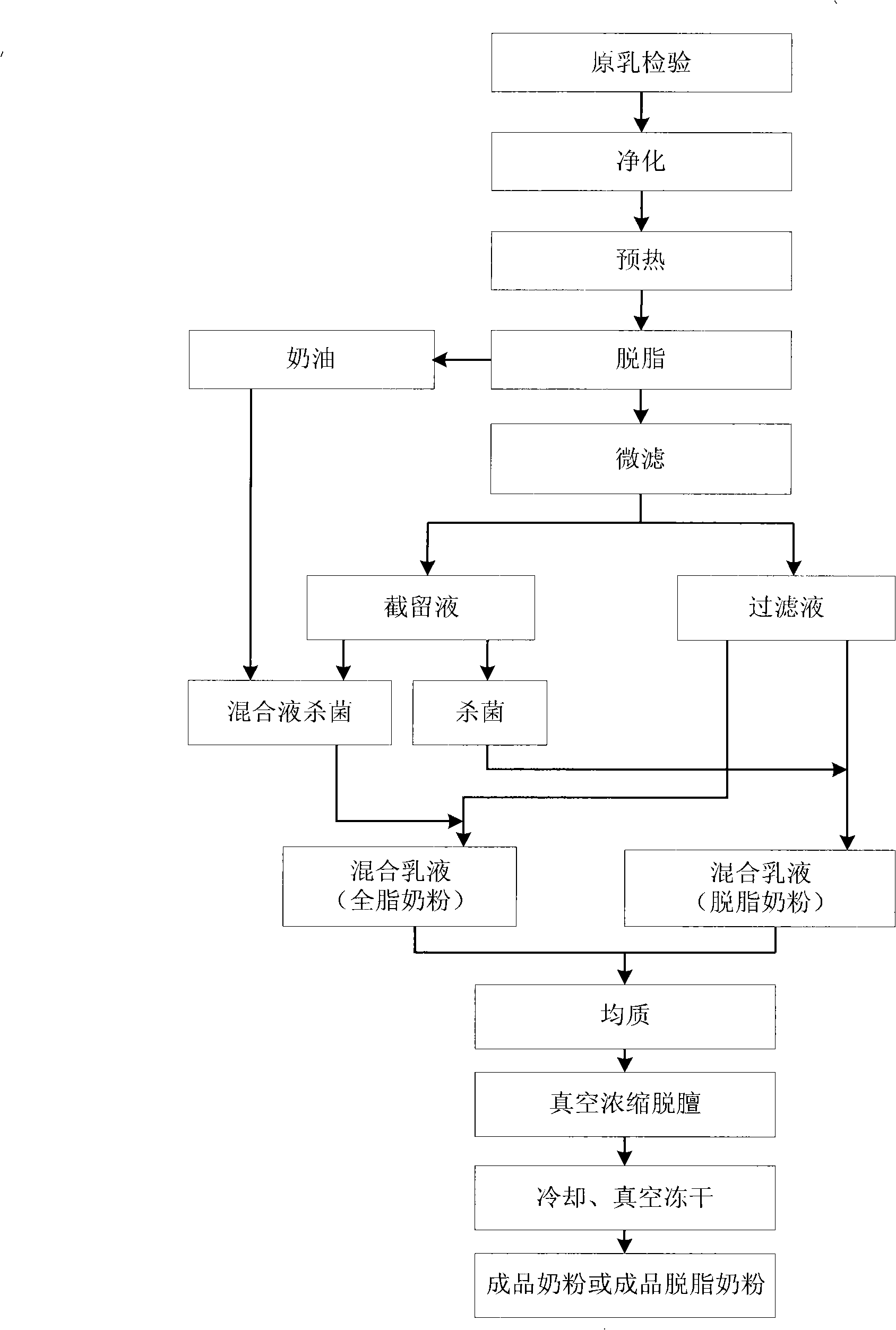

[0033] like figure 1 As shown, this implementation provides a production method of milk powder that preserves nutrition. After skimming the raw milk, the skim milk is sterilized by low-temperature microfiltration to ensure the nutrition in the skim milk to the greatest extent. This method can produce whole milk Whole-nutrition milk powder and skimmed whole-nutrition milk powder, the production method uses ceramic membrane microfiltration sterilization equipment to filter skimmed cow, goat milk or their colostrum to filter out miscellaneous bacteria, and the retention rate of miscellaneous bacteria is 99.94% %, the spore retention rate is 99.86%; the diameter of fat globules in cow and goat milk is between 0.1 and 22 microns, and the fat content of fat with small diameter in goat milk is relatively higher, because this size basically covers all the bacteria in the milk Therefore, before sterilization and filtration, the fat is separated; specifically, cow, goat milk or their co...

Embodiment 2

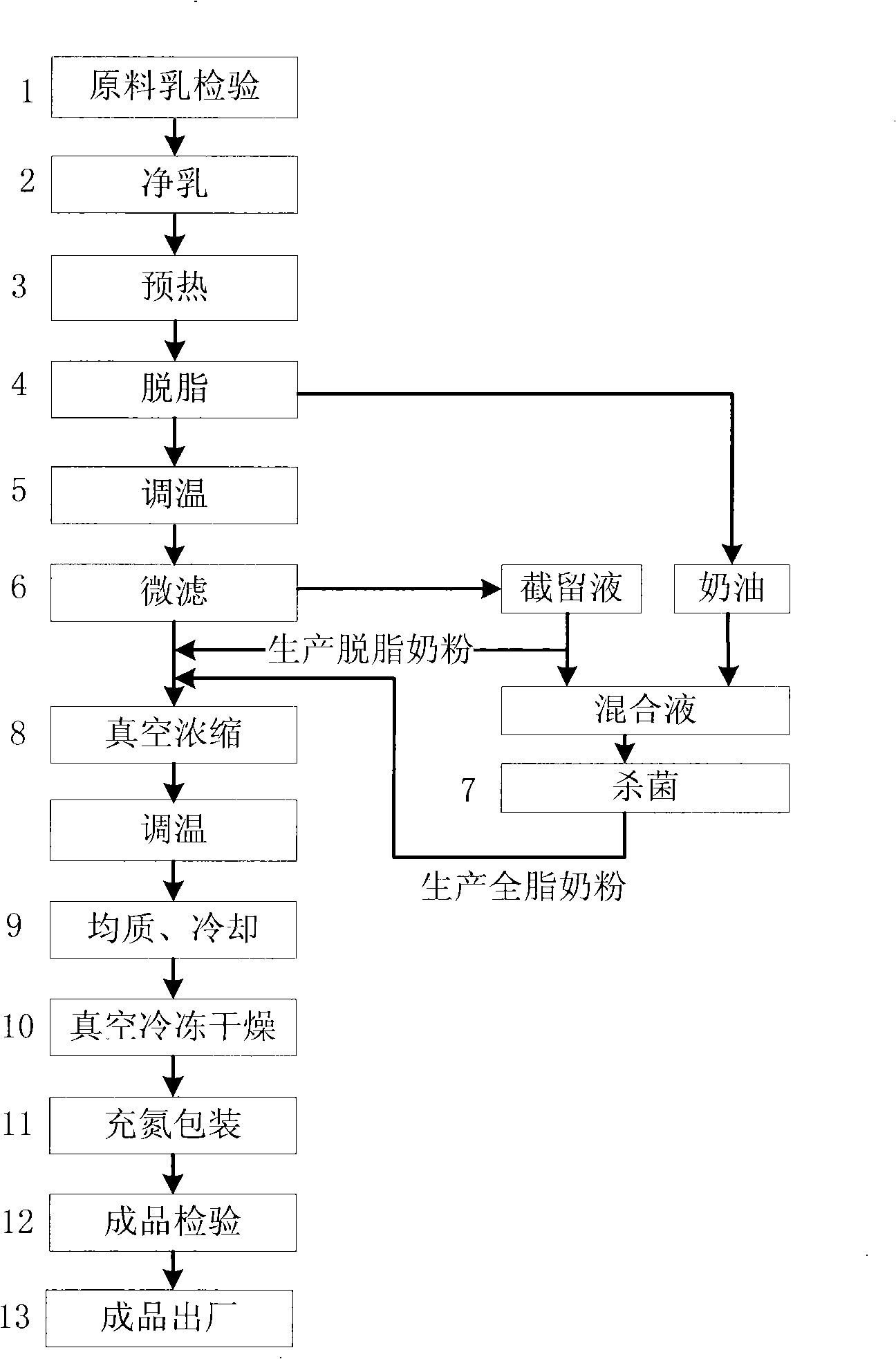

[0058] In this embodiment, fresh bovine raw milk is used as raw material to produce freeze-dried milk powder, and the production method of freeze-dried milk powder is described, specifically as follows:

[0059] Step 11. Raw milk inspection: inspect the fresh milk according to the quality inspection standard;

[0060] Step 12. Milk cleaning: Use a centrifuge at 45°C to perform high-speed separation to remove impurities, dust and various non-milk cells in the raw milk;

[0061] Step 13. Preheating: heat the purified purified milk to 38°C;

[0062] Step 14, degreasing: the degreasing machine separates the cream;

[0063] Step 15, temperature adjustment: the skim milk is adjusted to 50°C;

[0064] Step 16, Microfiltration: Put the skim milk into the microfiltration system, first pump it into the microfiltration tank, and then put it into the circulating microfiltration system by the feeding pump, adjust the microwave speed to 10m / s, and the reverse pulse frequency is 35 times / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com