Process for preparing potash magnesium sulphate fertilizer with kalium containing sulfate

A technology of potassium and magnesium sulfate fertilizer and sulfate ore, applied in the direction of magnesium fertilizer, potash fertilizer, application, etc., can solve the problem of no major breakthrough in the separation and extraction of potassium and magnesium sulfate fertilizer, achieve wide application range, increase potassium yield, reduce The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

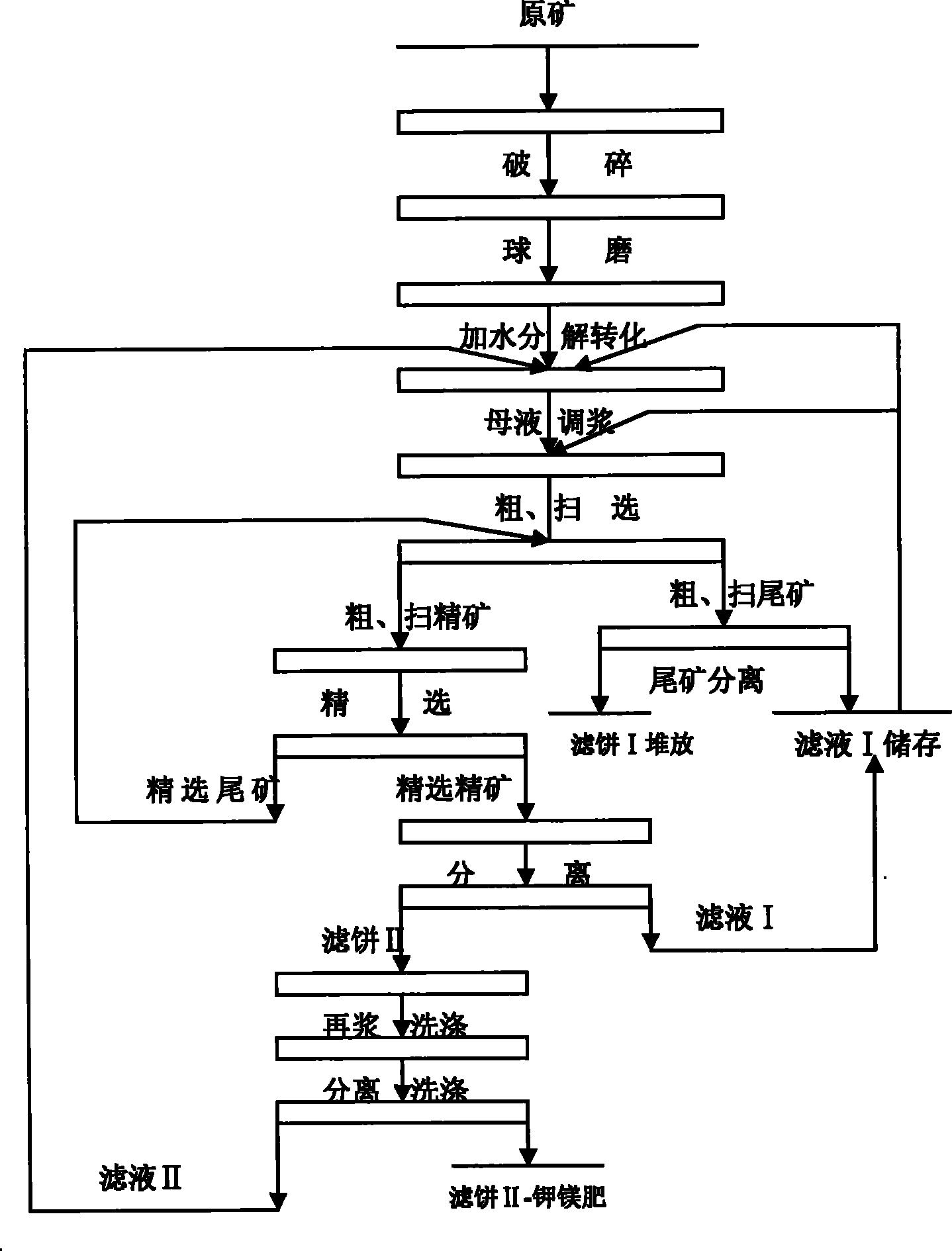

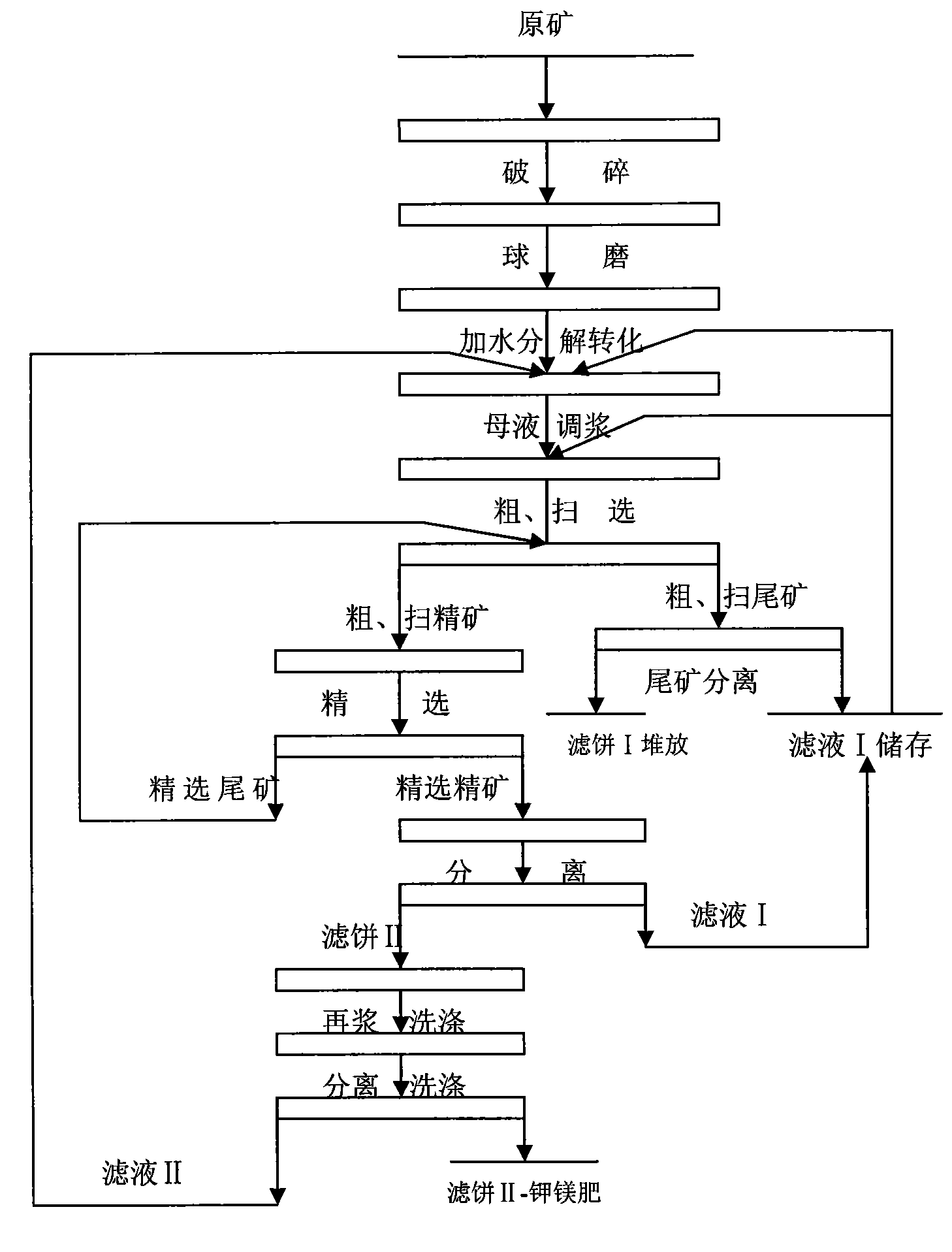

Image

Examples

Embodiment Construction

[0042] Below, the brine system points fall into Jinzuomei K, Mg, Na, Cl, SO 4 2- h 2 O five-element metastable system normal temperature phase diagram soft potassium magnesium vanadium phase zone sulfate-type salt lake potassium-containing brine salt field solar evaporation obtained potassium-containing sulfate ore as raw material, illustrating the process of the present invention to produce potassium magnesium sulfate fertilizer.

[0043] ①Preparation of potassium sulfate ore

[0044] Sulfate-type salt lakes, potassium-containing brines, and salt fields are evaporated in the sun to obtain a mixed ore containing soft potassium magnesium vanadium, potassium salt magnesium vanadium, potassium rock salt, and magnesium sulfate—potassium-containing sulfate ore (called sulfur mixed salt mine): the potassium-containing The sulfate-type salt lake brine is evaporated in the sun, and after sodium chloride is precipitated, the potassium-saturated brine is poured into the potassium-cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com