A kind of method for producing potassium sulfate and aluminum chloride by metathesis of potassium alum mixed solvent

A mixed solvent and potassium sulfate technology, which is applied in the preparation of aluminum chloride, aluminum halide, sulfate/bisulfate, etc., to achieve the effects of easy evaporation recovery, high raw material utilization rate, and high potassium yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

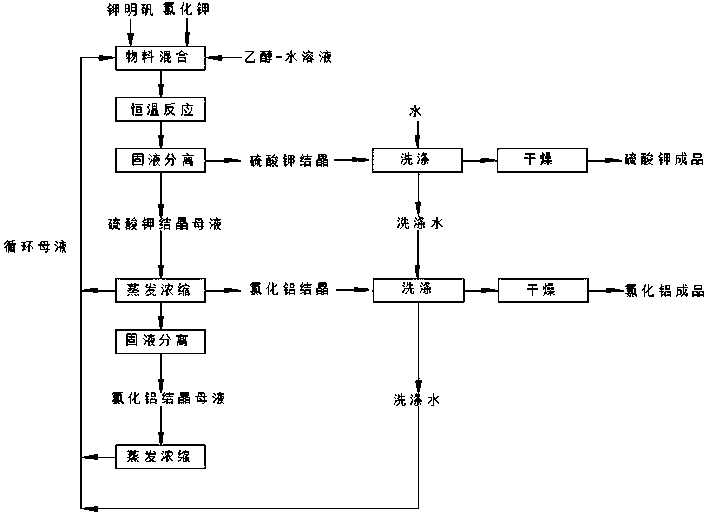

Image

Examples

Embodiment 1

[0026] Add 25g of potassium alum, 15g of potassium chloride and 100g of mixed solvent (90wt% ethanol content) into a sealed reactor, slowly heat to 50°C, and stir at a speed of 200r / min to make the mixture uniform, and at this temperature React for 60min, then separate the solid and liquid to obtain 115g of potassium sulfate crystal mother liquor and solid 1, solid 1 is washed and dried to obtain 20g of potassium sulfate crystal; after the potassium sulfate crystal mother liquor is evaporated and concentrated in a flash evaporator, adjust the temperature to 40°C, After crystallization 40min under the state of stirring speed of 200r / min, solid-liquid separation, obtain 100g aluminum chloride crystallization mother liquor and solid 2, solid 2 obtains 14g aluminum chloride crystallization after washing, drying; Potassium sulfate crystallization mother liquor evaporates concentration The condensate, the washing water after washing the crystals and the aluminum chloride crystallizat...

Embodiment 2

[0029] Add 35g of potassium alum, 20g of potassium chloride and 100g of mixed solvent (80wt% ethanol content) into the sealed reactor, slowly heat to 60°C, and stir at a speed of 200r / min to make the mixture uniform, and at this temperature React for 90min, then separate the solid and liquid to obtain 125g of potassium sulfate crystallization mother liquor and solid 1, solid 1 is washed and dried to obtain 25g of potassium sulfate crystal; After crystallization 40min under the state of stirring speed of 200r / min, solid-liquid separation, obtain 110g aluminum chloride crystallization mother liquor and solid 2, solid 2 obtains 18g aluminum chloride crystallization after washing, drying; Potassium sulfate crystallization mother liquor evaporates concentration The condensate, the washing water after washing the crystals and the aluminum chloride crystallization mother liquor are returned to be used for the dissolving of the salt after being evaporated to 100g.

[0030] The obtaine...

Embodiment 3

[0032] Add 40g potassium alum, 20g potassium chloride and 100g mixed solvent (70wt% ethanol content) into the sealed reactor, slowly heat to 70°C, and stir at 200r / min to make the mixture uniform, and at this temperature React for 60 minutes, then separate the solid and liquid to obtain 123g potassium sulfate crystalline mother liquor and solid 1, solid 1 is washed and dried to obtain 22g potassium sulfate crystals; after the potassium sulfate crystalline mother liquor is evaporated and concentrated in a flash evaporator, adjust the temperature to 55°C, After crystallization 40min under the state of stirring speed of 200r / min, solid-liquid separation, obtain 102g aluminum chloride crystallization mother liquor and solid 2, solid 2 obtains 23g aluminum chloride crystallization after washing, drying; Potassium sulfate crystallization mother liquor evaporates concentration The condensate, the washing water after washing the crystals and the aluminum chloride crystallization mother...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com