Respiration type construction energy-saving structure

A technology of building energy saving and air exhaust, which is applied to building components, building structures, buildings, etc., can solve the problems of increasing the heat transfer of outdoor cold air, poor effect, and high heat transfer coefficient of thin walls, so as to achieve strength assurance, The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

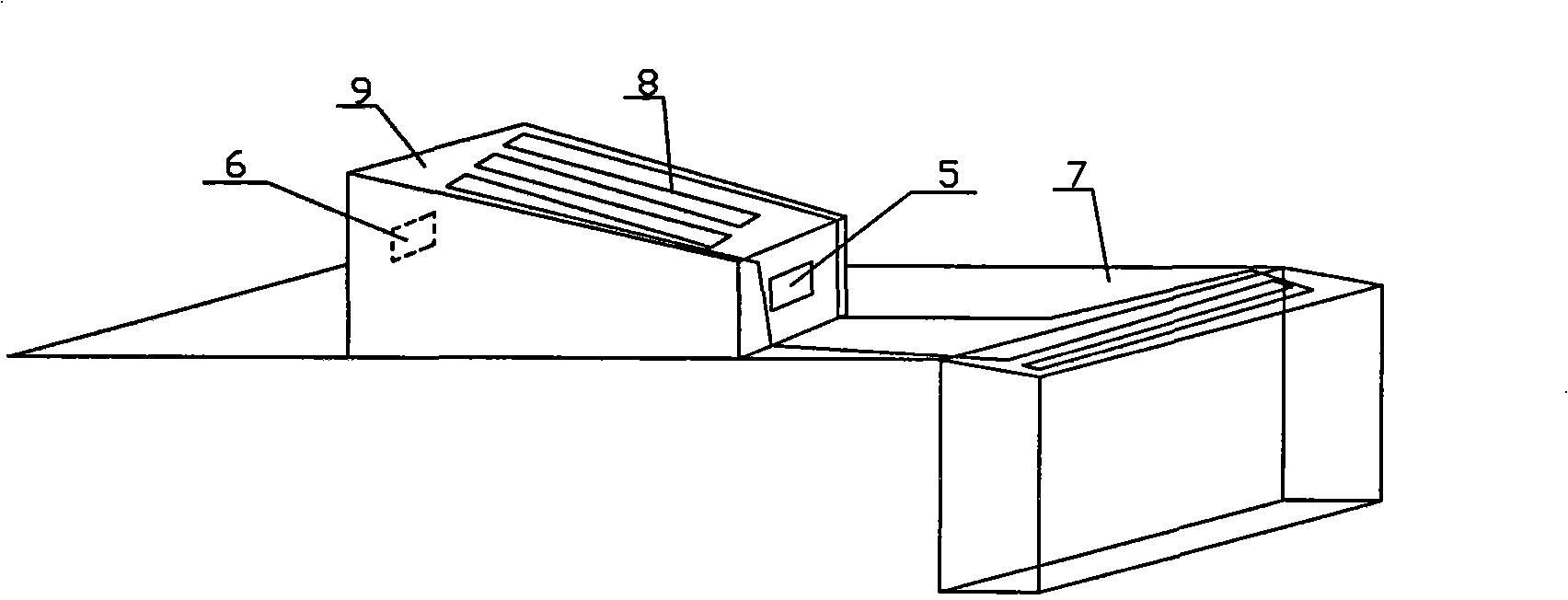

[0014] The breathable building energy-saving structure of the present invention includes two schemes, one is a sandwich wall, and the other is a stuffy roof.

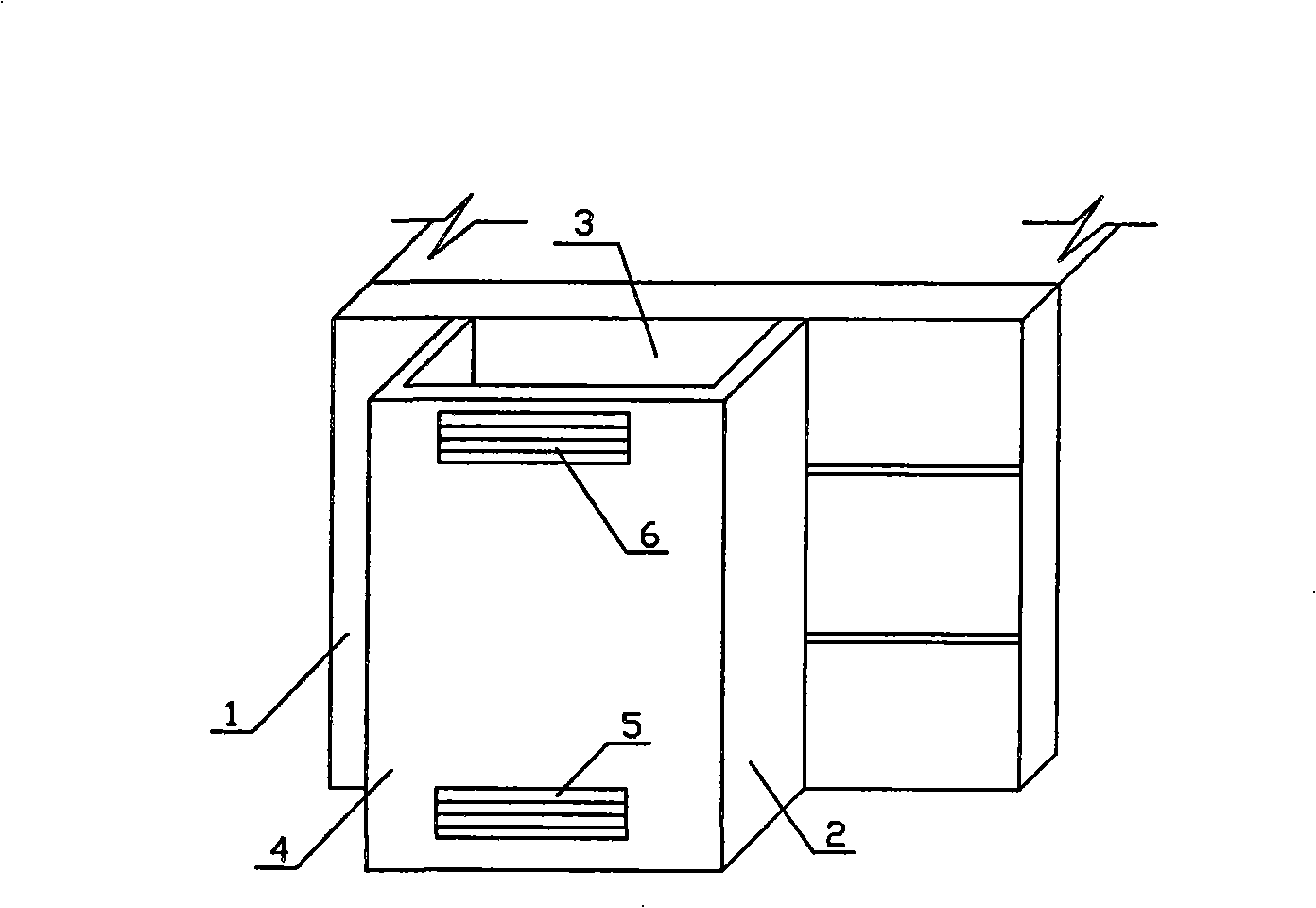

[0015] figure 1 It is a schematic diagram of the sandwich wall structure of the present invention. It can be seen from the figure that this breathable building energy-saving structure includes an outer wall 1, and at least part of the outer wall 1 is a sandwich wall 2. Generally speaking, the outer wall of the sandwich wall is set The body is the side that receives more sunlight. The interlayer part of the interlayer wall is the airflow channel 3, and the width of the channel is 300-500mm. The lower part of the outer wall 4 of the interlayer wall is provided with an air inlet 5, and the upper part of the outer wall of the interlayer wall is provided with an air outlet 6. All the air ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com