Optimization design method of micro-electron packaging device based on artificial neural network

A technology of artificial neural network and microelectronic packaging, applied in biological neural network models, instruments, calculations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

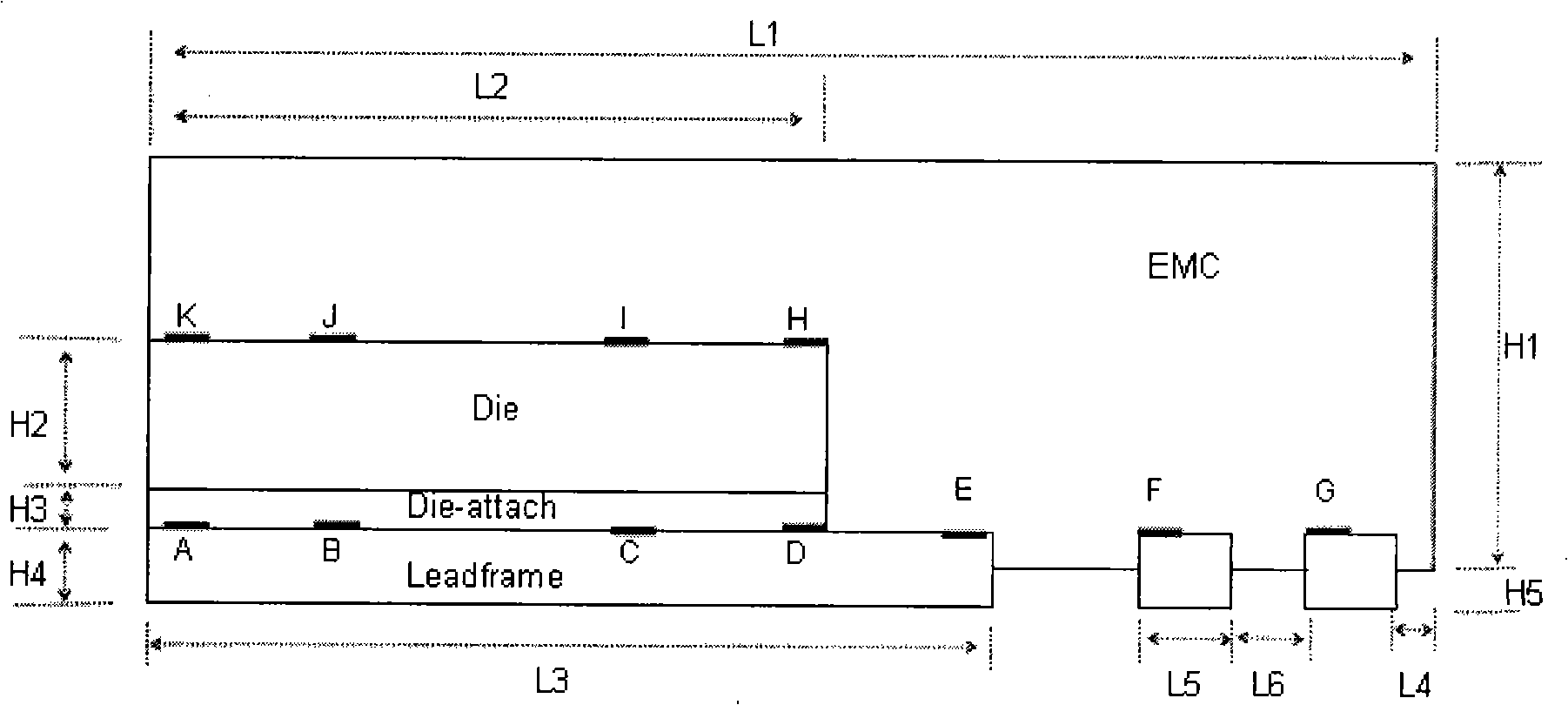

[0090] The user hopes to optimize the design of the QFN device according to the interface lamination failure between the silicon wafer adhesive DA and the lead-frame (lead-frame) under the comprehensive influence of humidity, heat and steam pressure as the design criterion. Such as image 3 shown. The loading process is: from the end of the package mold filling, after 186hr85℃HR85% pretreatment, then lead-free reflow soldering and cooling to -65℃.

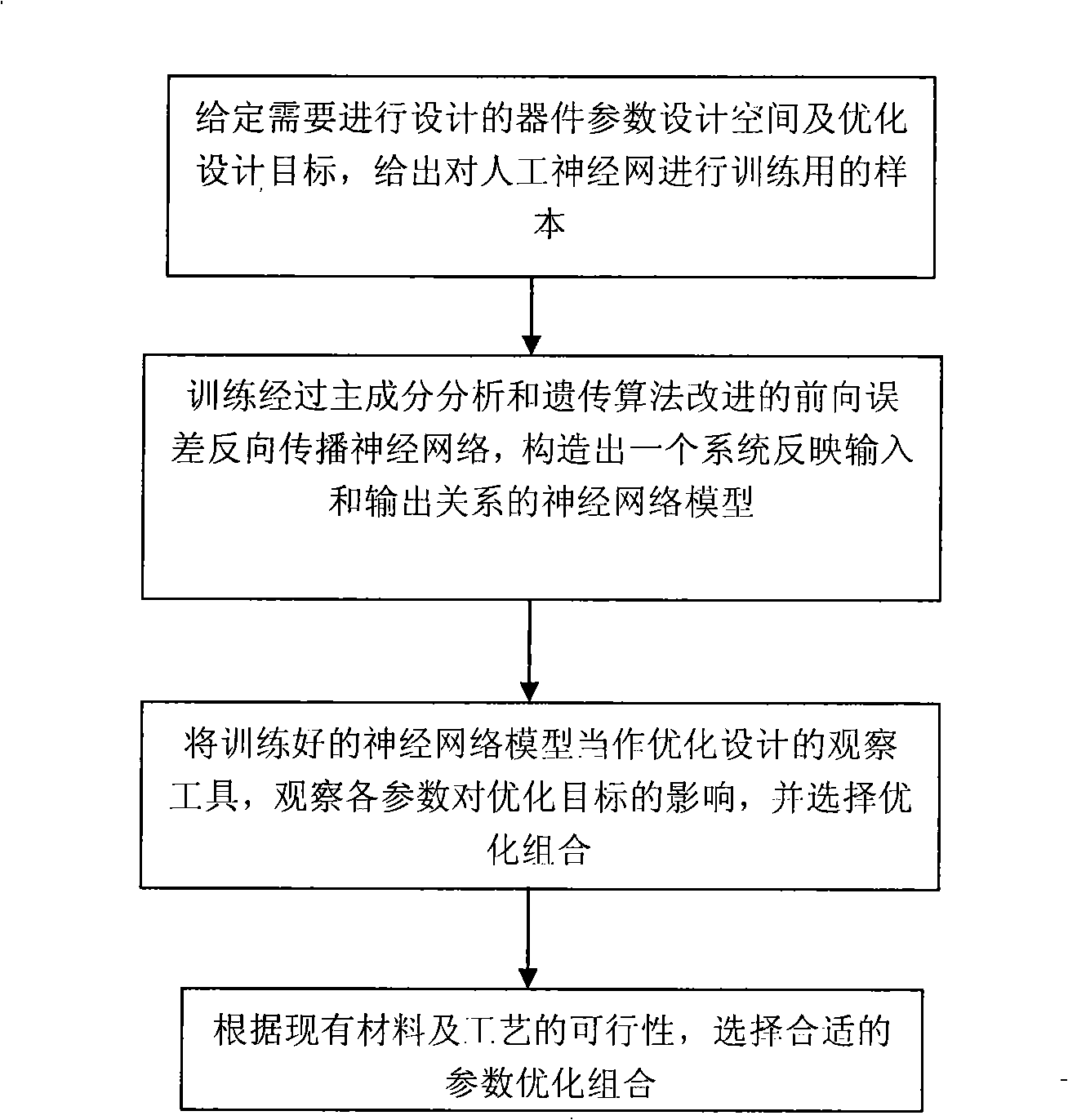

[0091] (1) The user specifies the device parameter design space to be designed and the optimization design goal, performs finite element analysis and analysis according to the uniform experiment method, and provides samples for training the artificial neural network.

[0092] (1.1) Designation of design parameters

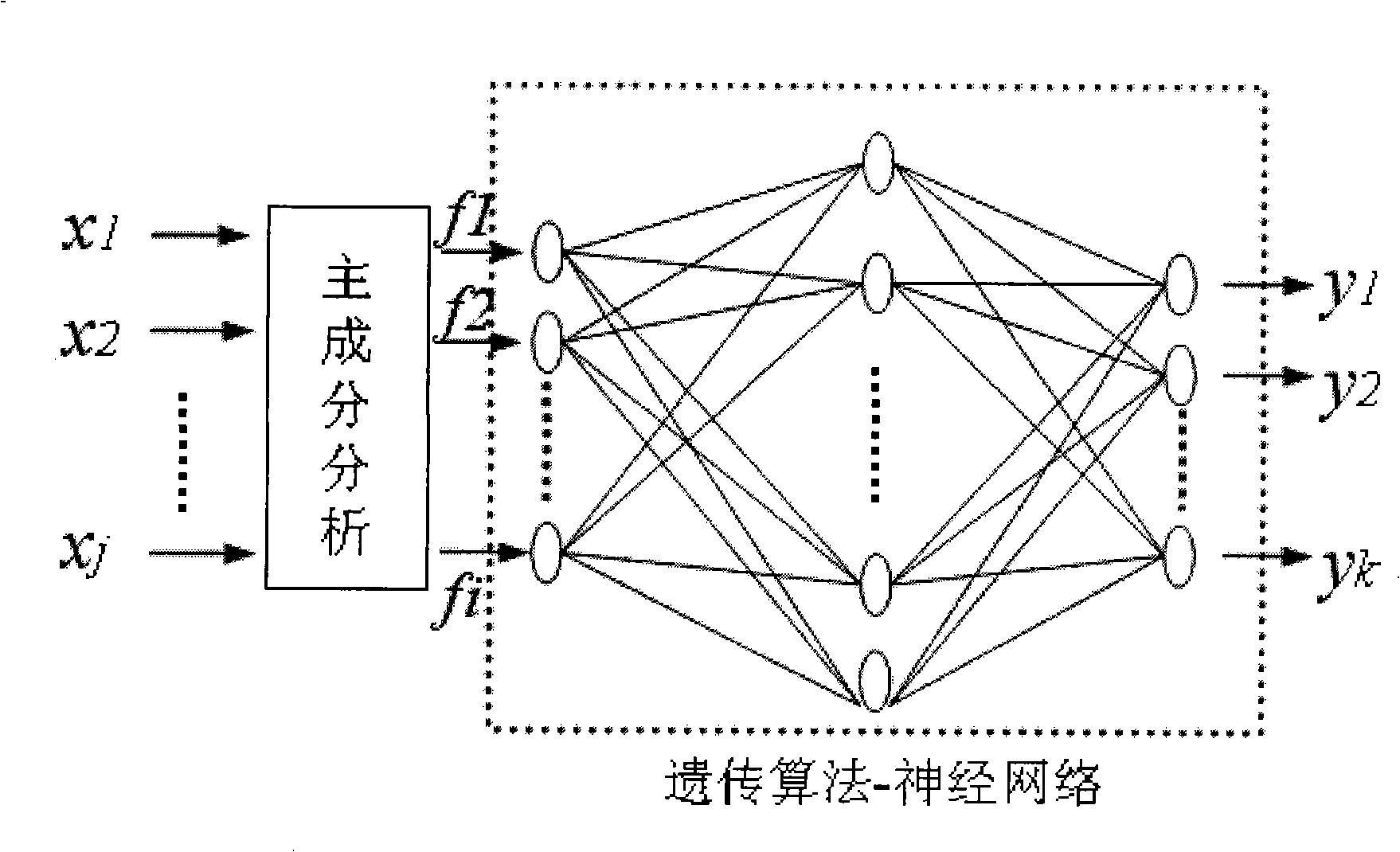

[0093] The user specifies to optimize and select 6 material parameters of Young's modulus E (MPa) and thermal expansion coefficient α (ppm / ℃) of EMC, DA and lead-frame materials, and 6 structural parameters: the width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com