Electrolyte material of low temperature oxide fuel battery and preparation method thereof

A technology of electrolyte materials and low temperature oxides, which is applied in the parts of fuel cells, fuel cells, solid electrolyte fuel cells, etc., can solve the problem of poor stability of materials and fuel cells, can not guarantee complete uniformity of two phases, and fast power decay and other problems, to achieve the effect of solving corrosion and long-term stability, excellent fuel cell performance, and reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

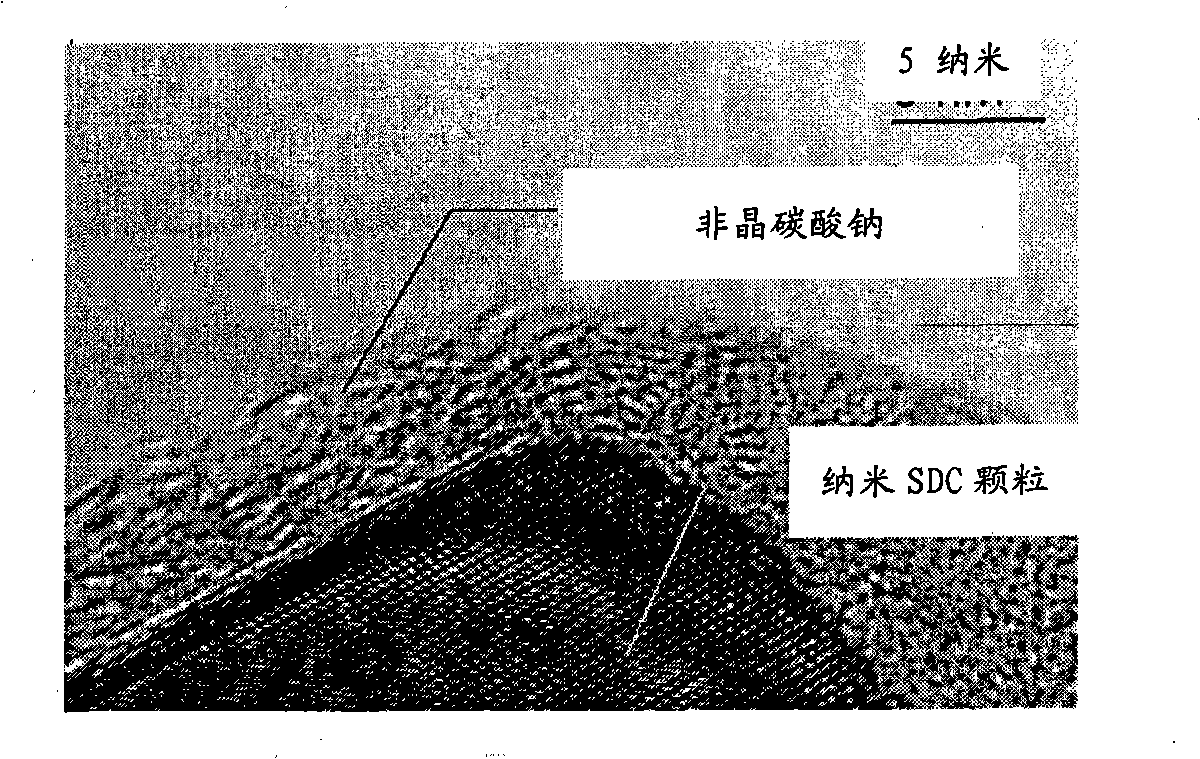

[0028] Prepare 0.1 mole of cerium nitrate with 500 ml of deionized water or distilled water to prepare cerium nitrate solution, and repeat the preparation of 4 parts of the same cerium nitrate solution; dissolve 0.15, 0.2, 0.3, 0.4 moles of sodium carbonate in 500 ml of deionized water or distilled water to prepare into sodium carbonate solution; under heating at 80-150°C or without heating and stirring, add the four kinds of sodium carbonate solutions to the above 4 parts of the same cerium nitrate solution respectively to obtain 4 kinds of Ce / CO 3 = White precipitates of cerium oxide-sodium carbonate in molar ratios of 1:1.5, 1:2, 1:3 and 1:4, respectively. For each type, the resulting precipitate and water are divided into two parts that are equal (or not equal); one part is directly stirred, heated, and boiled until it is almost dry, and then placed in an oven at 120 ° C for 12-24 hours to obtain cerium oxide- Dry precursor of sodium carbonate; add 500 ml of deionized wat...

Embodiment 9-16

[0030] 0.1 mole of cerium nitrate is prepared into a cerium nitrate solution with 500 milliliters of deionized water or distilled water, and 4 parts of the same cerium nitrate solution are prepared repeatedly; 0.15, 0.2, 0.3, 0.4 moles of potassium carbonate are respectively dissolved with 500 milliliters of deionized water or distilled water, Prepare potassium carbonate solutions with different concentrations; add the above four potassium carbonate solutions to cerium nitrate solutions respectively under heating at 80-150°C or without heating and stirring to obtain four different Ce / CO 3 = The molar ratios are 1:1.5, 1:2, 1:3 and 1:4 white precipitates; for each of them, the resulting precipitates and water are divided into two equal parts: one part is directly stirred, heated, boiled until When it is almost dry, put it in an oven at 80-200°C for 12-24 hours until it is dry; add 500 ml of deionized water or distilled water to the other part, stir well, and filter it until it ...

Embodiment 17-24

[0032] Mix 0.1 mole of cerium nitrate with 500 milliliters of deionized water or distilled water to prepare cerium nitrate solution, and repeat the preparation of 4 parts of the same cerium nitrate solution; dissolve 0.15, 0.2, 0.3, 0.4 moles of Na in 500 milliliters of deionized water or distilled water: K The mixture of sodium carbonate and potassium carbonate in a molar ratio of 1:1 is prepared into mixed solutions of sodium carbonate and potassium carbonate with different concentrations. Add the four kinds of carbonate mixed solutions to each cerium nitrate solution under heating or without heating and stirring at 80-150°C to obtain four kinds of Ce / CO 3 = White precipitates with molar ratios of 1:1.5, 1:2, 1:3 and 1:4 respectively; divide the obtained precipitates together with water into two equal parts: one part is directly stirred, heated, boiled until almost dry, put into Keep in the oven at 80-200°C for 12-24 hours until dry; add 500 ml of deionized water or distill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com