Modified chitosan metal composite wood preservative and method for producing the same

A technology of wood preservatives and metal composites, applied in the direction of wood impregnation, impregnated wood, manufacturing tools, etc., can solve the problem of broad-spectrum antibacterial, bactericidal, insecticidal, reduce the permeability of preservatives to bamboo wood, and metal ions Low binding rate and other problems, to achieve the effect of improving anti-corrosion effect, wide application range, and improving anti-loss performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

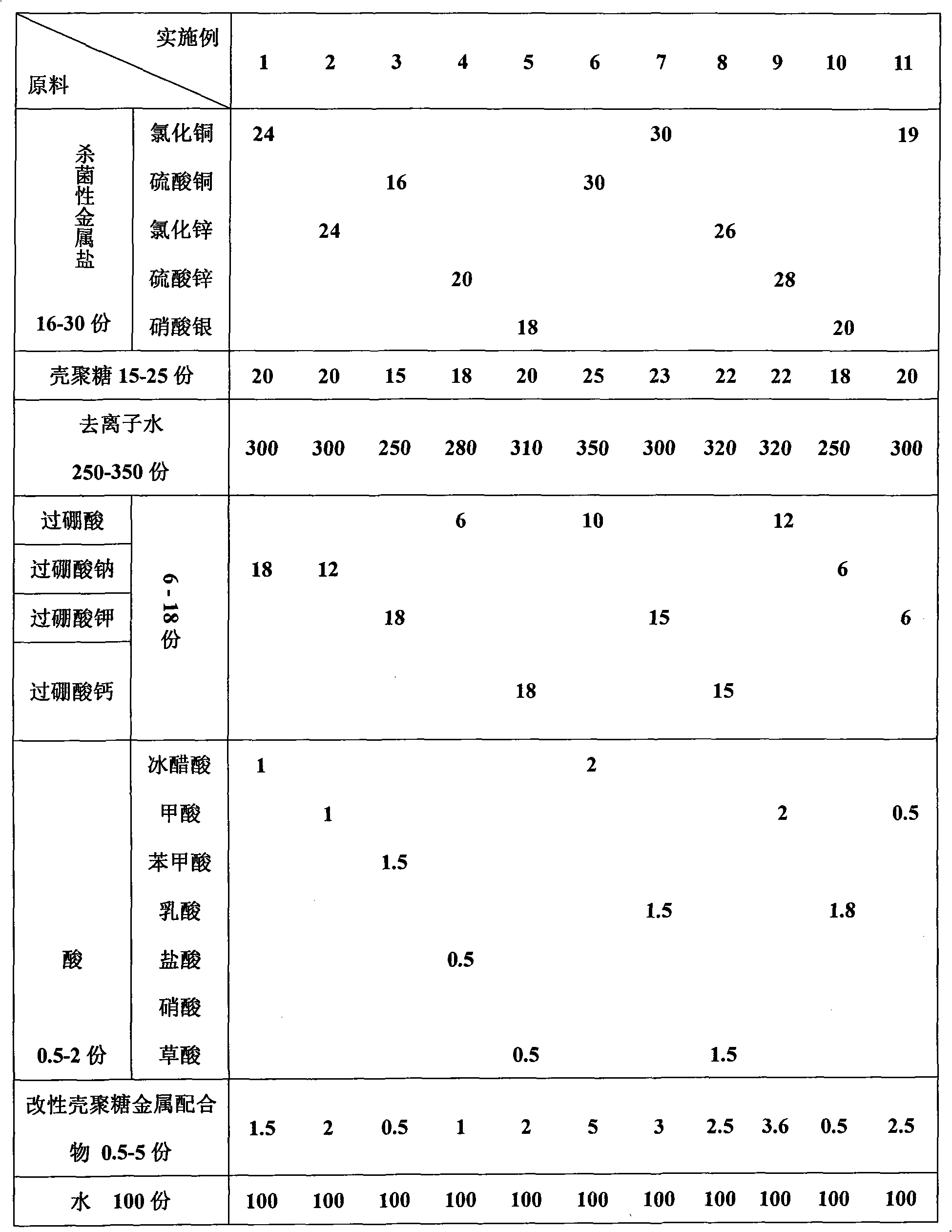

[0020] Embodiment 1 (contrast the raw material and proportioning weight part of embodiment 1 column in table 1):

[0021] First prepare the modified chitosan metal complex: dissolve 18 parts of sodium perborate in 300 parts of deionized water, then add 24 parts of copper chloride, and slowly add 20 parts of chitosan with a molecular weight of 40 mesh and a molecular weight of 360,000 while stirring. powder (the weight ratio of metal salt to chitosan is 1.2:1), adjust the pH value of the solution to 4.5, and stir at 55° C. for 3 h. After the reaction, centrifuge and wash the insoluble part with water 2-3 times until the insoluble part does not contain free copper ions, then dry the insoluble part at 60±2°C to obtain the modified chitosan copper complex product. The content of copper ions in the modified chitosan copper complex is 16.2% as detected by atomic absorption spectrophotometer, and the content of boron element as tested by plasma emission spectrometry is 1.3%.

[0022...

experiment example

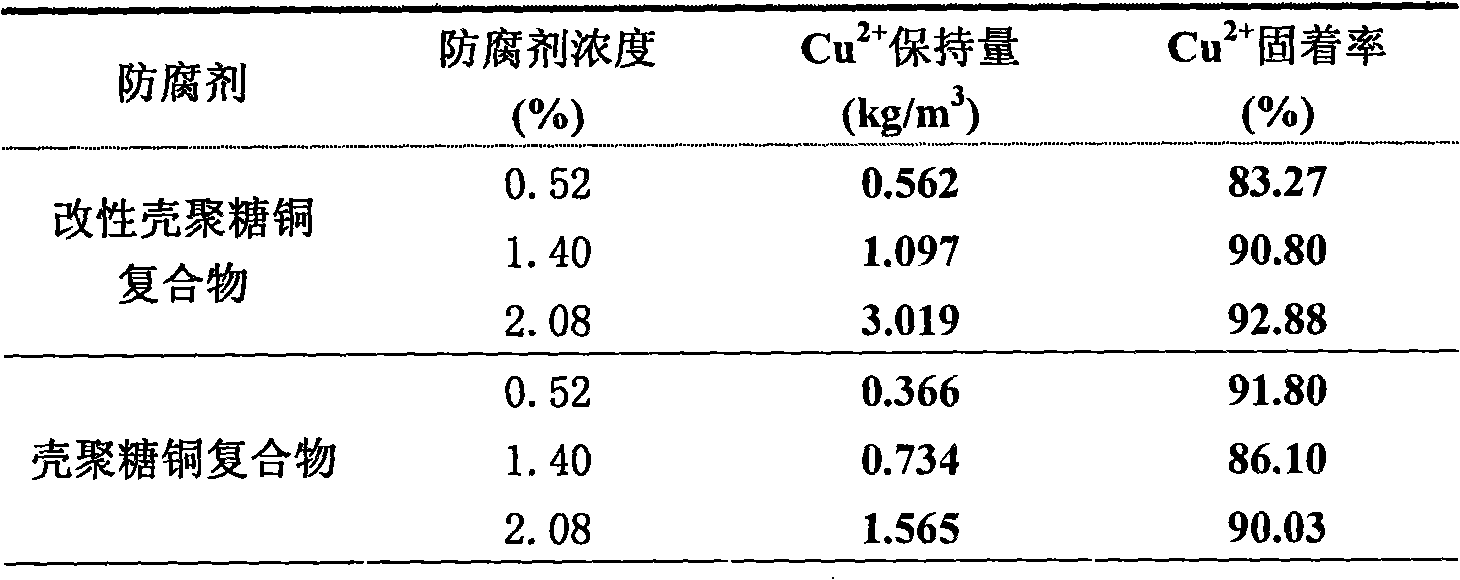

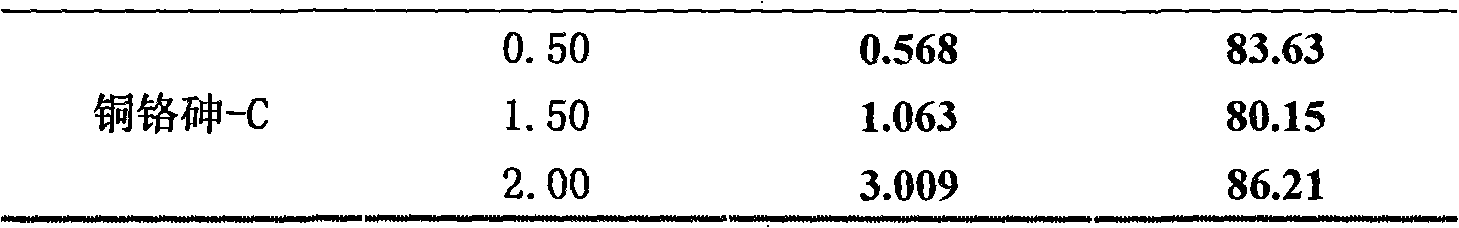

[0024] According to "Laboratory Test Method of Toxicity of Wood Preservatives to Decay Fungi" LY / T1283-1998, the anti-loss performance of the above-mentioned concentration of wood protective agents was compared with the other two protective agents. The results are shown in Table 2:

[0025] Table 2 Modified chitosan copper complex, chitosan copper complex, copper chromium arsenic preservative

[0026] Anti-loss test results in Poplar tomentosa wood

[0027]

[0028]

[0029] Note: The injection of preservatives adopts the vacuum method, the vacuum degree is 0.9MPa, and the vacuum time is 30min.

[0030] The data in table 2 shows that the modified chitosan copper complex preservative has more drug absorption than the chitosan copper complex preservative under the same treatment concentration, indicating that the modified chitosan copper complex preservative is to the penetration of wood sex increased. The fixation rates of modified chitosan copper complex preservative a...

Embodiment 2

[0041] Embodiment 2 (contrast the corresponding raw material and the proportioning value in parts by weight of embodiment 2 column in table 1):

[0042]First prepare the modified chitosan metal complex: 12 parts of sodium perborate are dissolved in 300 parts of distilled water, then add 24 parts of zinc chloride, slowly add 20g 40 mesh molecular weight while stirring and be 360,000 chitosan powder ( The weight ratio of metal salt to chitosan is 1.2:1), the pH value of the solution is adjusted to 5.5, and stirred at 50° C. for 3 hours. After the reaction, centrifuge and wash the insoluble part with water 2-3 times until the insoluble part does not contain free zinc ions, then dry the insoluble part at 60±2°C to obtain the modified chitosan zinc complex product. The content of zinc ions in the modified chitosan zinc complex is 15.4% as detected by atomic absorption spectrophotometer, and the content of boron element as tested by plasma emission spectrometry is 1.6%.

[0043] Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com