Preparation of light hydrogen occluding alloy

A hydrogen storage alloy, light-weight technology, applied in the field of hydrogen storage materials, can solve the problem of less hydrogen storage materials, and achieve the effects of low cost, low equipment investment, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

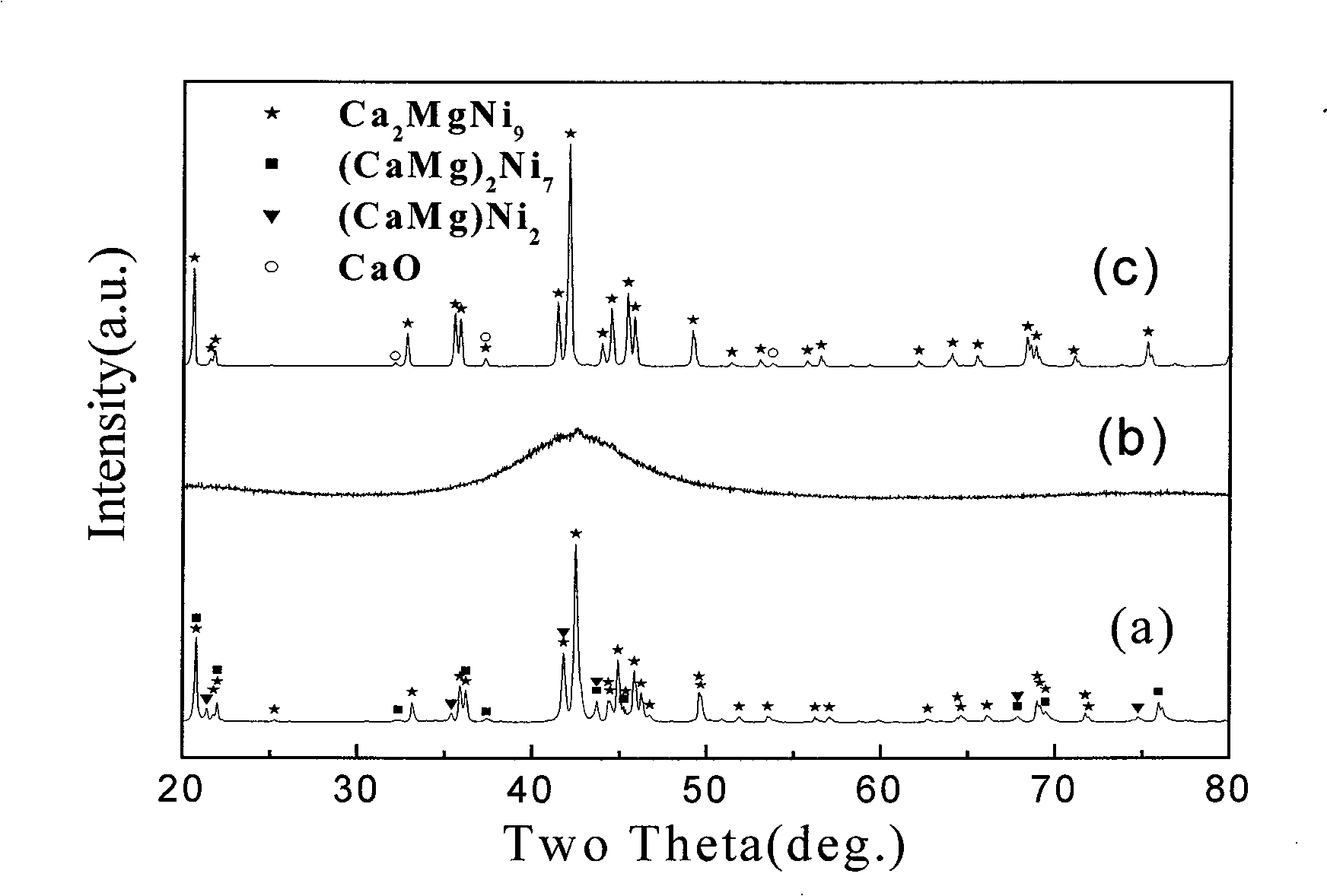

[0026] The metal Ca particles have a purity of 99.0%; the metal Mg powder has a purity of 99.7% and a particle size of 200 mesh; and the metal Ni flakes have a purity of 99.9%. Press Ca 2 MgNi 9 Alloy Molecular Formula Weigh a certain amount of raw metal (add appropriate burning loss to Ca and Mg), and smelt it twice under 18KW power to obtain a multi-phase alloy. The alloy phase is (CaMg)Ni 3 、(CaMg)Ni 2 and (CaMg) 2 Ni 7 ( figure 2 (a)Ca 2 MgNi 9 (AB 3 type) alloy magnetic levitation melting sample X-ray diffraction pattern). Grind the smelted alloy into a 100 mesh in a mortar and put it into a stainless steel tank, put the stainless steel tank in a planetary ball mill and mill it under argon protection for 48 hours (the ratio of ball to material is 10:1) to obtain an amorphous alloy ( figure 2 (b) Ca 2 MgNi 9 (AB 3 type) X-ray diffraction pattern of the alloy amorphous sample). The amorphous alloy powder is pressed into a φ13×3mm green body in a stainless ste...

Embodiment 2

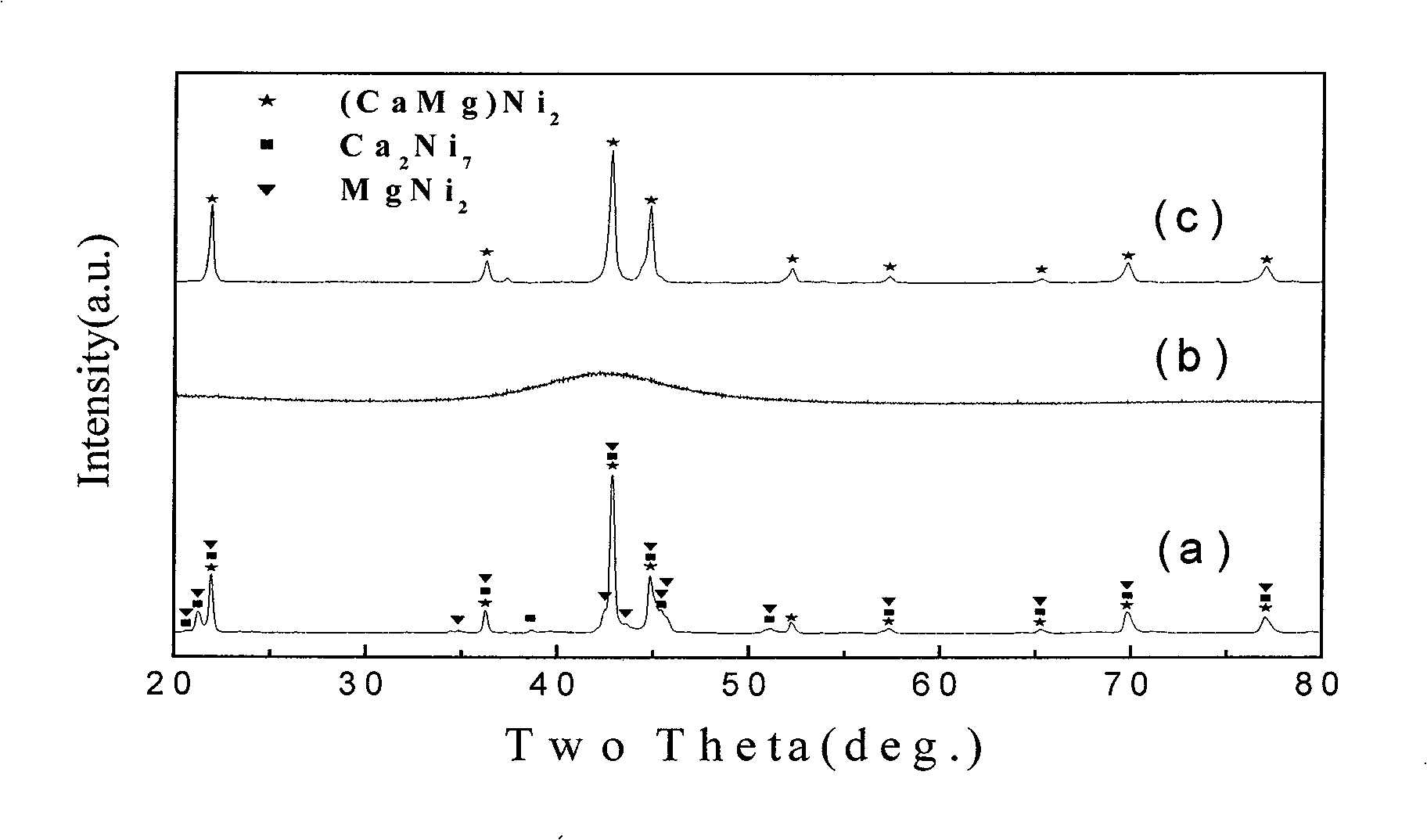

[0028] The metal Ca particles have a purity of 99.0%; the metal Mg powder has a purity of 99.7% and a particle size of 200 mesh; and the metal Ni flakes have a purity of 99.9%. By (CaMg)Ni 2 Alloy Molecular Formula Weigh a certain amount of raw metal (add appropriate burning loss to Ca and Mg), and smelt it twice under 18KW power to obtain a multi-phase alloy. The alloy phase is (CaMg)Ni 2 , Ca 2 Ni 7 and MgNi 2 ( image 3 (a)(CaMg)Ni 2 (AB 2 type) alloy magnetic levitation melting sample X-ray diffraction pattern). Grind the smelted alloy into a 100 mesh in a mortar and put it into a stainless steel tank, put the stainless steel tank in a planetary ball mill and mill it under argon protection for 48 hours (the ratio of ball to material is 10:1) to obtain an amorphous alloy ( image 3 (b)(CaMg)Ni 2 (AB 2type) X-ray diffraction pattern of the alloy amorphous sample). Amorphous alloy powder is pressed into a φ13×3mm green body in a stainless steel abrasive tool at 30 M...

Embodiment 3

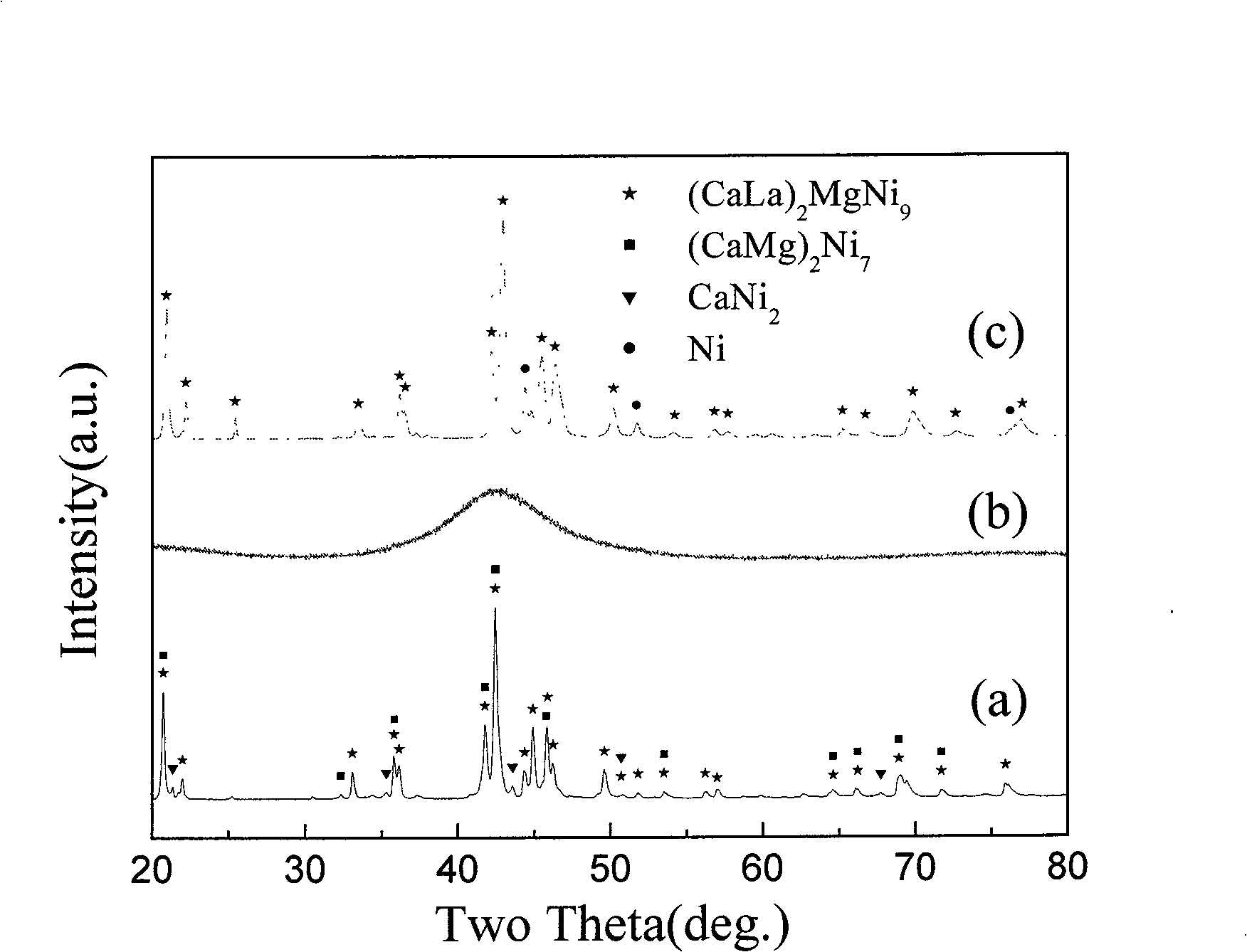

[0030] The metal Ca particles have a purity of 99.0%; the metal La blocks have a purity of 99.5%; the metal Mg powder has a purity of 99.7% and a particle size of 200 mesh; and the metal Ni flakes have a purity of 99.9%. Press (CaLa) 2 MgNi 9 Alloy Molecular Formula Weigh a certain amount of raw material metal (add appropriate burning loss to Ca, La and Mg), and smelt twice under 18KW magnetic levitation to obtain a multi-phase alloy. The alloy phase is (CaLa) 2 MgNi 9 , (CaMg) 2 Ni 7 and CaNi 2 ( image 3 (a)(CaLa) 2 MgNi 9 (AB 3 type) alloy magnetic levitation melting sample X-ray diffraction pattern). Grind the smelted alloy into a 100 mesh in a mortar and put it into a stainless steel tank, put the stainless steel tank in a planetary ball mill and mill it under argon protection for 48 hours (the ratio of ball to material is 10:1) to obtain an amorphous alloy ( image 3 (b)(CaLa) 2 MgNi 9 (AB 3 type) X-ray diffraction pattern of the alloy amorphous sample). Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com