External pressure type temperature compensation high-temperature high-pressure optical fiber grating sensor

A temperature compensation, high temperature and high pressure technology, used in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of small detection range, large detection error, low sensitivity, etc., to overcome the elastic hysteresis effect and improve linearity. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

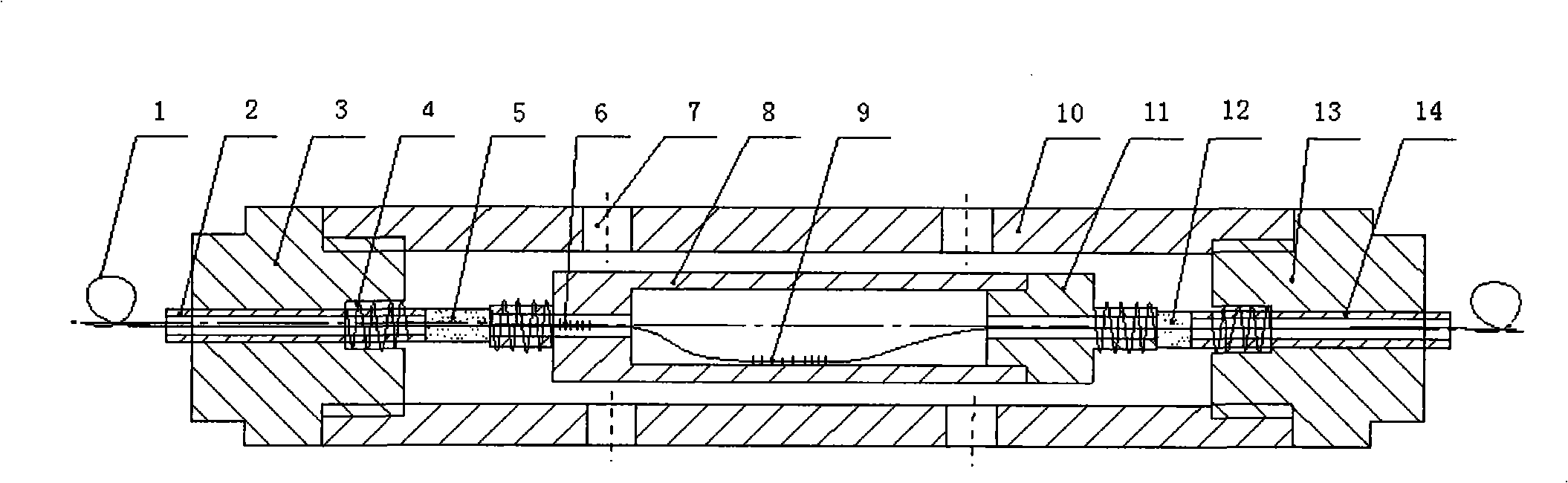

[0018] exist figure 1 Among them, the external pressure temperature compensation high temperature and high pressure fiber grating sensor of this embodiment consists of an optical fiber 1, a left capillary metal tube 2, a left outer protection tube joint 3, a spring 4, a left heat shrinkable tube 5, a temperature sensing fiber grating 6, Oil inlet hole 7, quartz tube 8, pressure sensing fiber grating 9, outer protection tube 10, quartz plug 11, right heat-shrinkable tube 12, right outer protection tube joint 13, and right capillary metal tube 14 are connected.

[0019] This embodiment adopts an optical fiber 1, and the optical fiber 1 is a quartz single-mode optical fiber. On the left side of the optical fiber 1, a temperature sensing fiber grating 6 is written. The manufacturing wavelength of the temperature sensing fiber grating 6 is 1549nm. Sensing fiber grating 6 is only used to feel the temperature of downhole oil and natural gas. On the right side of optical fiber 1, pres...

Embodiment 2

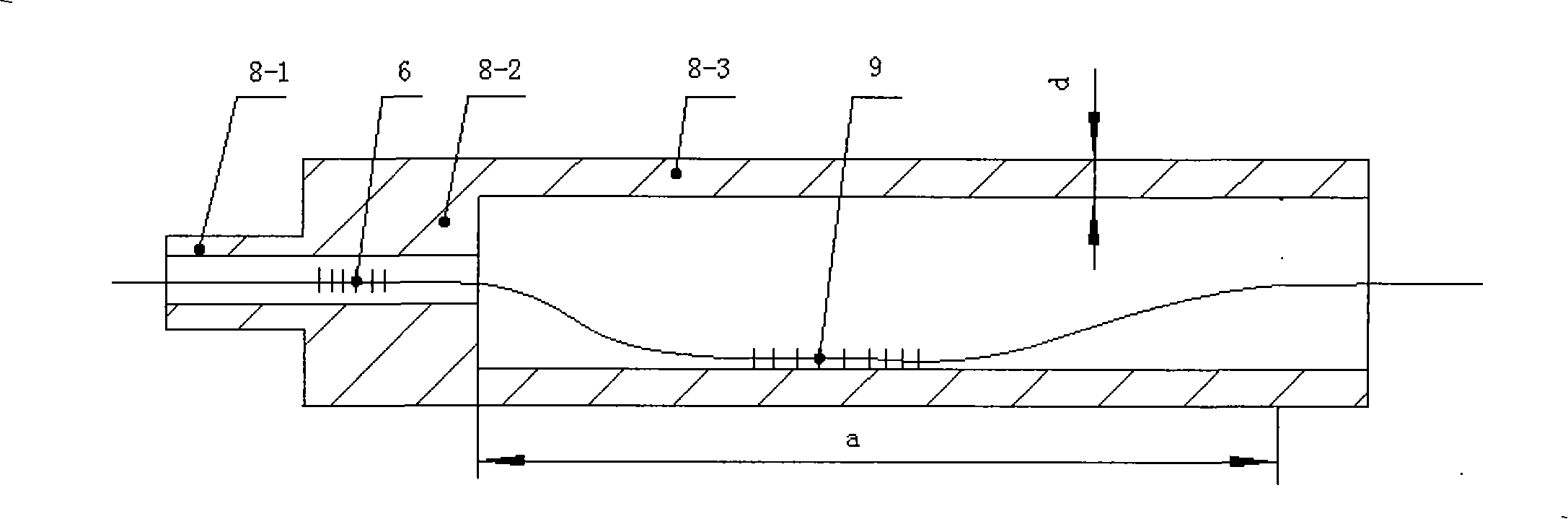

[0022] In the present embodiment, the wall thickness d of the pressure tube 8-3 is 1.0mm, and the effective length a of the pressure tube 8-3 (the length of the pressure tube 8-3 minus the length of the inserting part of the quartz plug 11) is 50mm. The fabrication wavelength of the temperature sensing fiber Bragg grating 6 is 1532nm, and the fabrication wavelength of the pressure sensing fiber Bragg grating 9 is 1530nm. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0024] In the present embodiment, the wall thickness d of the pressure tube 8-3 is 1.5mm, and the effective length a of the pressure tube 8-3 (the length of the pressure tube 8-3 minus the length of the inserting part of the quartz plug 11) is 70mm. The fabrication wavelength of the temperature sensing fiber Bragg grating 6 is 1552nm, and the fabrication wavelength of the pressure sensing fiber Bragg grating 9 is 1550nm. Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com