Ferrocene extinguishment experiment system

An experimental system and ferrocene technology are applied in the field of experimental systems for fire extinguishing performance of fire extinguishing agents, which can solve problems such as expanding the application range of ferrocene and achieve good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

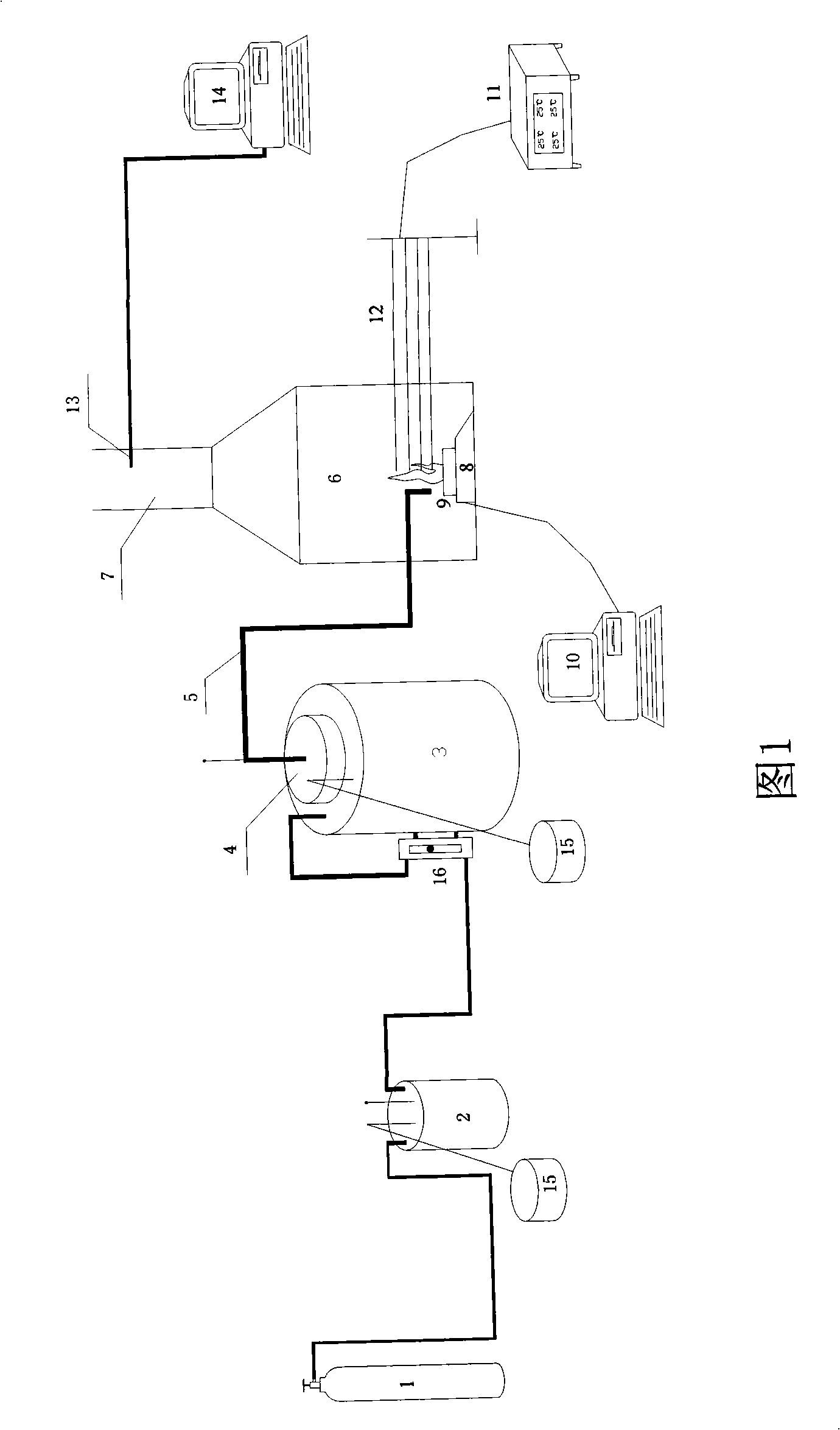

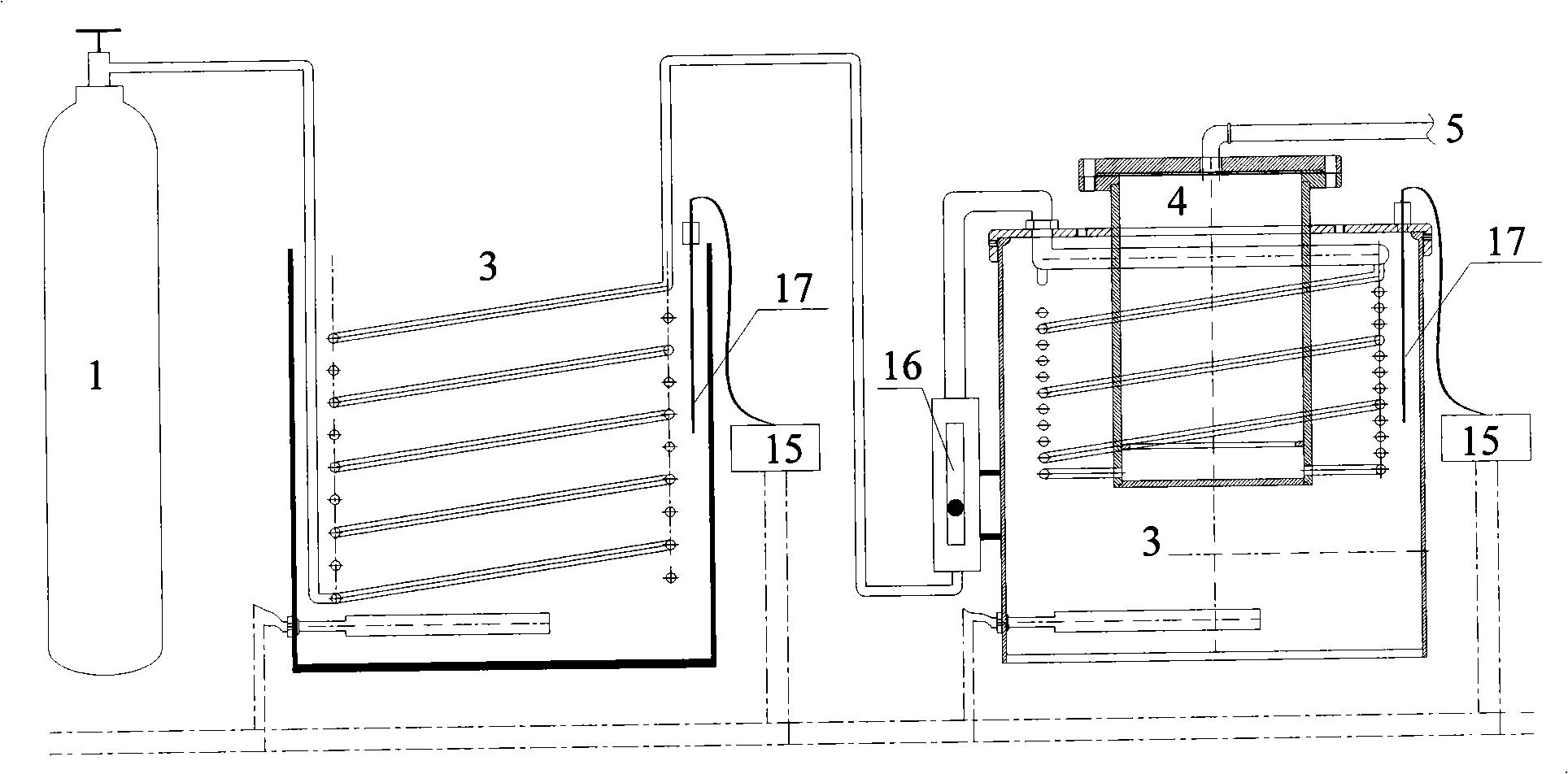

[0022] The ferrocene fire extinguishing experimental system of the present invention comprises a ferrocene evaporation device and a fire extinguishing platform, wherein the ferrocene evaporation device includes a carrier gas source 1, a constant temperature water bath 2, a constant temperature oil bath 3 and a ferrocene evaporation chamber 4, The carrier gas source 1 is connected to the constant temperature water bath 2 to preheat the carrier gas, the constant temperature water bath 2 is connected to the constant temperature oil bath 3, the ferrocene evaporation chamber 4 is placed in the constant temperature oil bath 3, and the constant temperature oil bath 3 heats the carrier gas; The constant temperature water bath 2 and the constant temperature oil bath 3 are respectively connected to the digital display temperature controller 15. A rotameter 16 is installed between the constant temperature water bath 2 and the constant temperature oil bath 3 to control the flow of the carr...

Embodiment 2

[0033] The experimental system is the same as in Example 1.

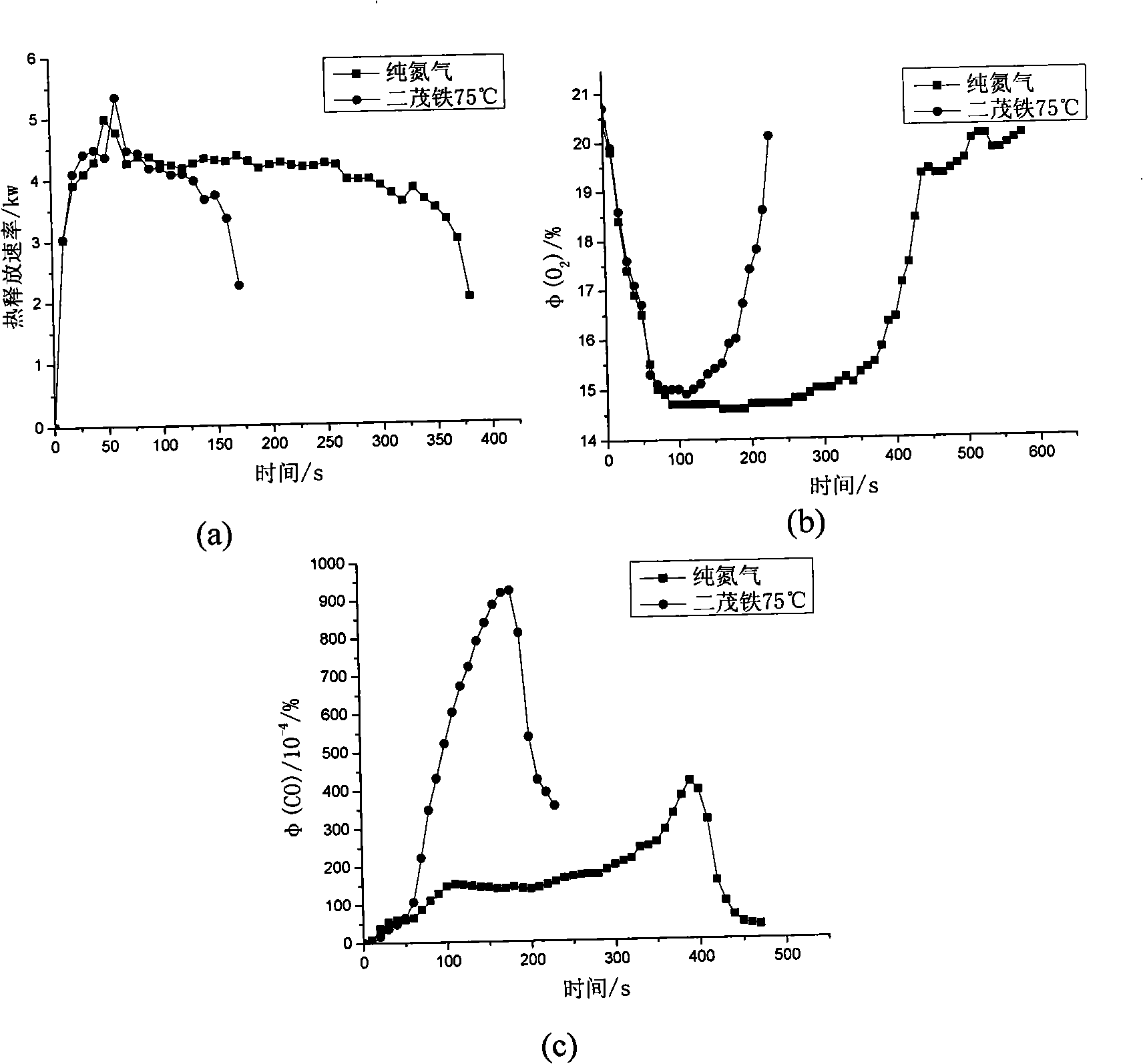

[0034] Pre-pass the carrier gas before the experiment and use the rotameter to fix the flow rate of the carrier gas at 1.0m 3 / h, heat the water bath to 70°C, since the boiling point of glycerol is 290°C, the temperature of the oil bath can be changed to obtain different concentrations of ferrocene.

[0035] From the experiment, the concentration changes of oxygen, carbon dioxide and carbon monoxide in the flue gas under the action of different concentrations of ferrocene, the mass change and combustion efficiency of the fuel during the combustion process, and the heat release of the fuel can be calculated according to the mass change and combustion efficiency of the fuel rate.

Embodiment 3

[0037] The experimental system is the same as in Example 1.

[0038] Pre-pass the carrier gas before the experiment and use the rotameter to fix the flow of the carrier gas. Since the range of the rotameter is 0-2.5m3 / h, the flow of the carrier gas can be changed to obtain the oxygen and carbon dioxide in the flue gas at different flow rates of the carrier gas. and the concentration change of carbon monoxide, the mass change and combustion efficiency of the fuel during the combustion process, and the heat release rate of the fuel can be calculated according to the mass change and combustion efficiency of the fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com