Semiconductor lighting fixture having high-efficiency heat radiation structure and manufacture method thereof

A technology of heat dissipation structure and lighting lamps, which is applied in semiconductor devices of light-emitting elements, lighting and heating equipment, lighting devices, etc., which can solve the problems of poor heat dissipation performance and high manufacturing cost, and achieve simple and reliable structure, high heat dissipation efficiency, and uniform illumination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

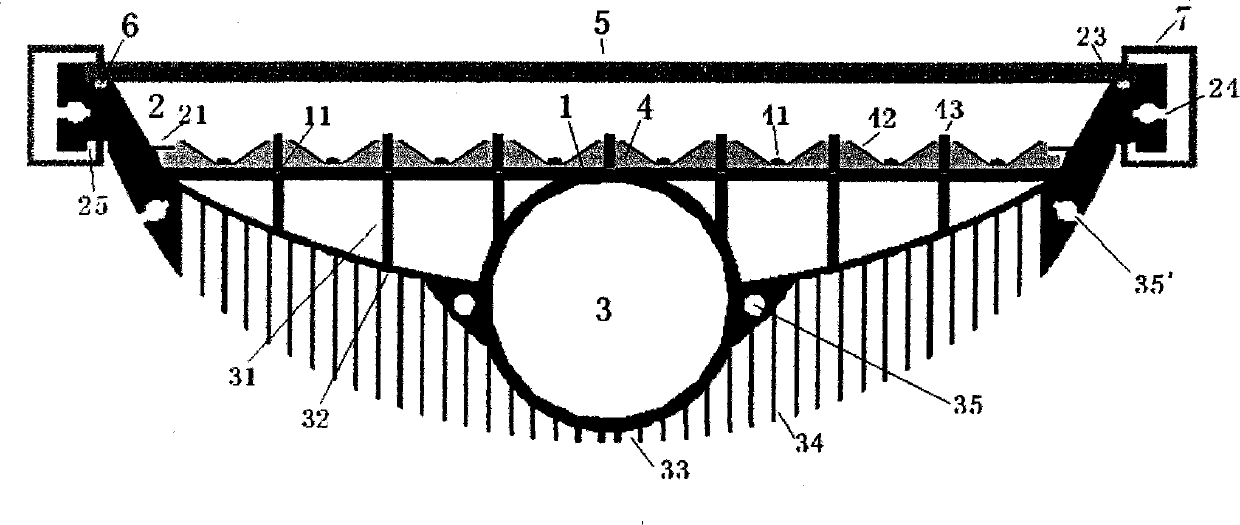

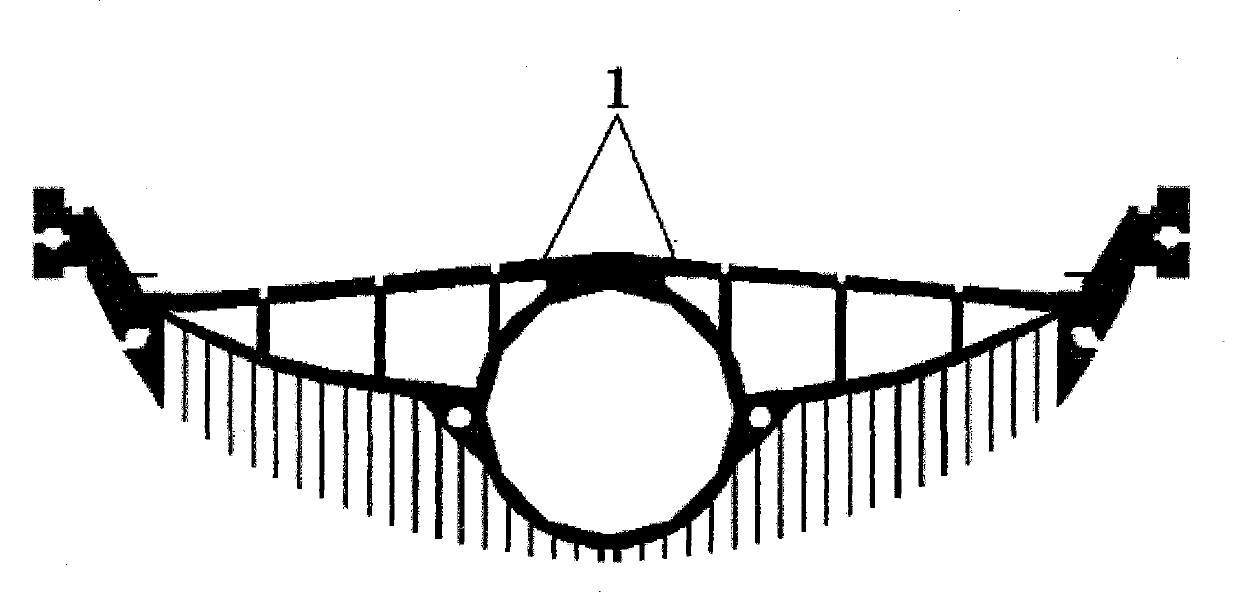

[0018] Taking a street lamp as an example to describe the lamp structure of the present invention in detail, the lamp profile cross-sectional structure shown in Fig. 500mm, the length can be cut arbitrarily according to the needs; there is a screw installation groove 11 for installing the light source module on the surface, which is used for the installation and fixing of the light source module and the substrate; the light source substrate 1 is connected with the reflective support side plate 2, and the angle between them is 90-160 degrees; the thickness of the reflective support side plate 2 is 2-20mm, and the height is 10-50mm; the bottom of the reflective support side plate 2 has an installation edge 21 to facilitate the installation of the light source module 4; the surface of the reflective support side plate 2 is smooth A good reflective surface is used to reflect the light emitted by the light source module 4 and improve the luminous efficiency of the lamp;

[0019] Th...

Embodiment 2

[0023] According to different application requirements, the light source substrate 1 can be flat, as shown in Figure 1(a), or it can be a light source substrate with a certain angle, as shown in Figure 2(c), the light source substrate consists of two flat plates, Or as shown in Figure 2(d), the light source substrate is composed of three flat panels, or a curved panel with a certain radian to form the light source substrate, and the light distribution of the lamp can be flexibly performed through the included angle or radian to obtain uniform illuminance.

Embodiment 3

[0025] The light source module 4 in the power semiconductor lighting module shown in FIG. 3( e ) can be mounted on the bottom light source substrate 1 and the reflective support side plate 2 . The reflective support side plate 2 is connected to the bottom light source substrate 1, and the angle between them is 90-160 degrees. The number of light source modules 4 installed on the reflective support side plate 2 and the angle between the reflective support side plate 2 and the bottom light source substrate 1 can all affect the light output effect of the entire lamp, thereby achieving the purpose of dimming. If no light source module is installed on the side light source substrate of the power semiconductor lighting module shown in Figure 3(e), its structure is similar to that of the lighting module shown in Figure 1(a), at this time, the reflective support side plate 2 can be It is regarded as a side light source substrate.

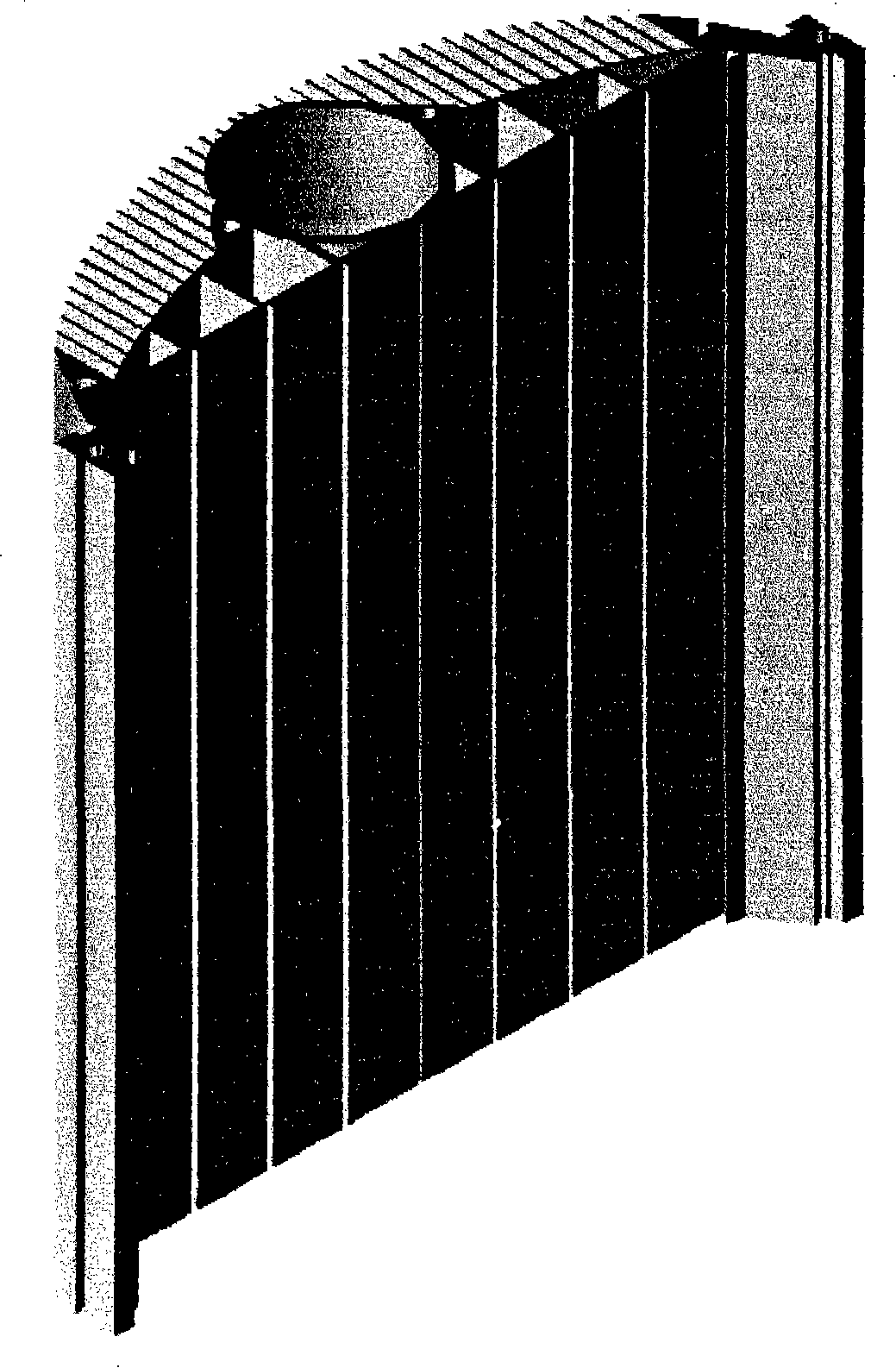

[0026] The heat dissipation structure of the power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com