Sheet laser micro-drawing forming method and device with synchro heating

A technology of micro-deep drawing and sheet metal, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of inconvenient blank holder, low work efficiency, and affecting the quality of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

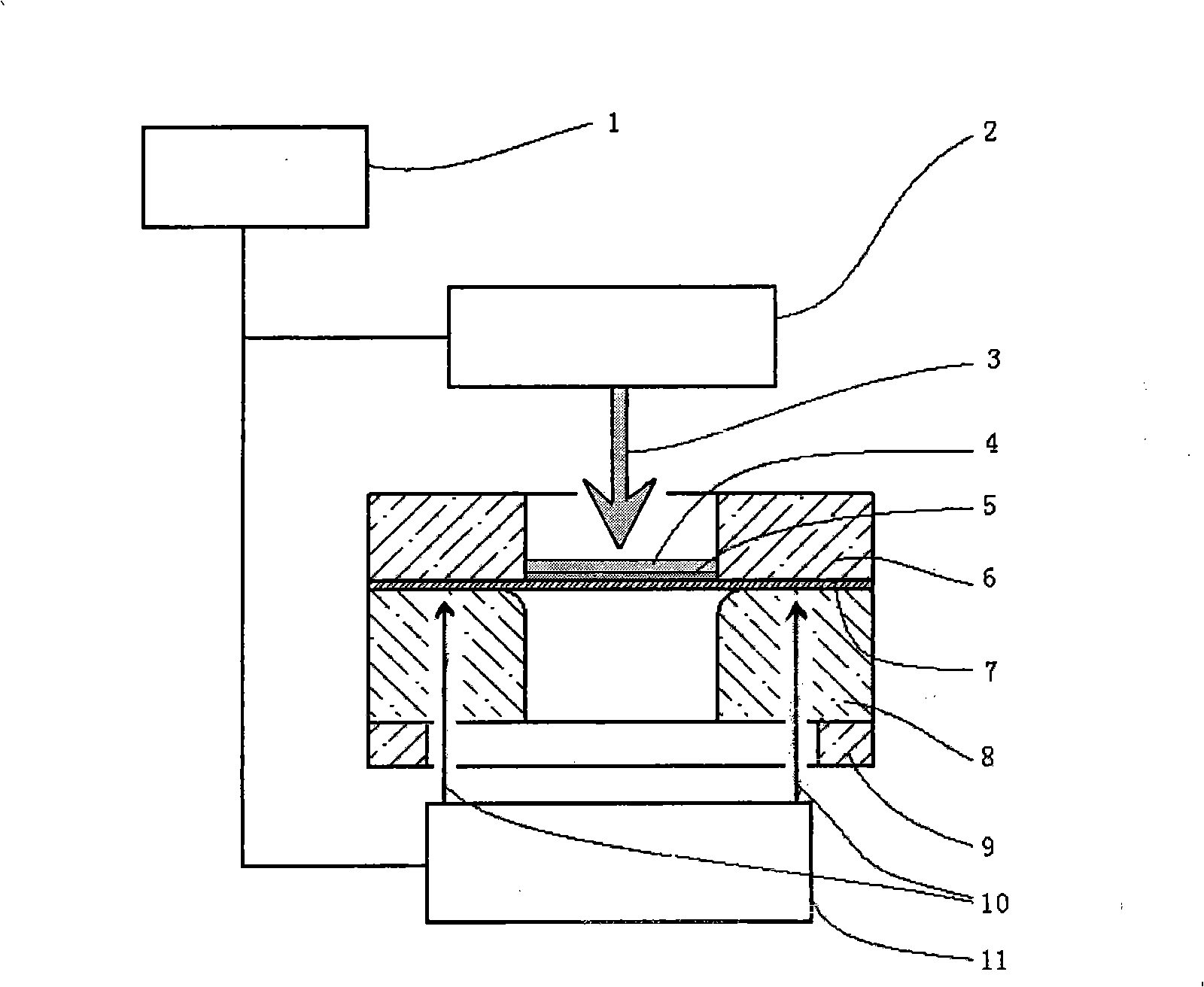

[0008] Technical scheme of the present invention is as follows:

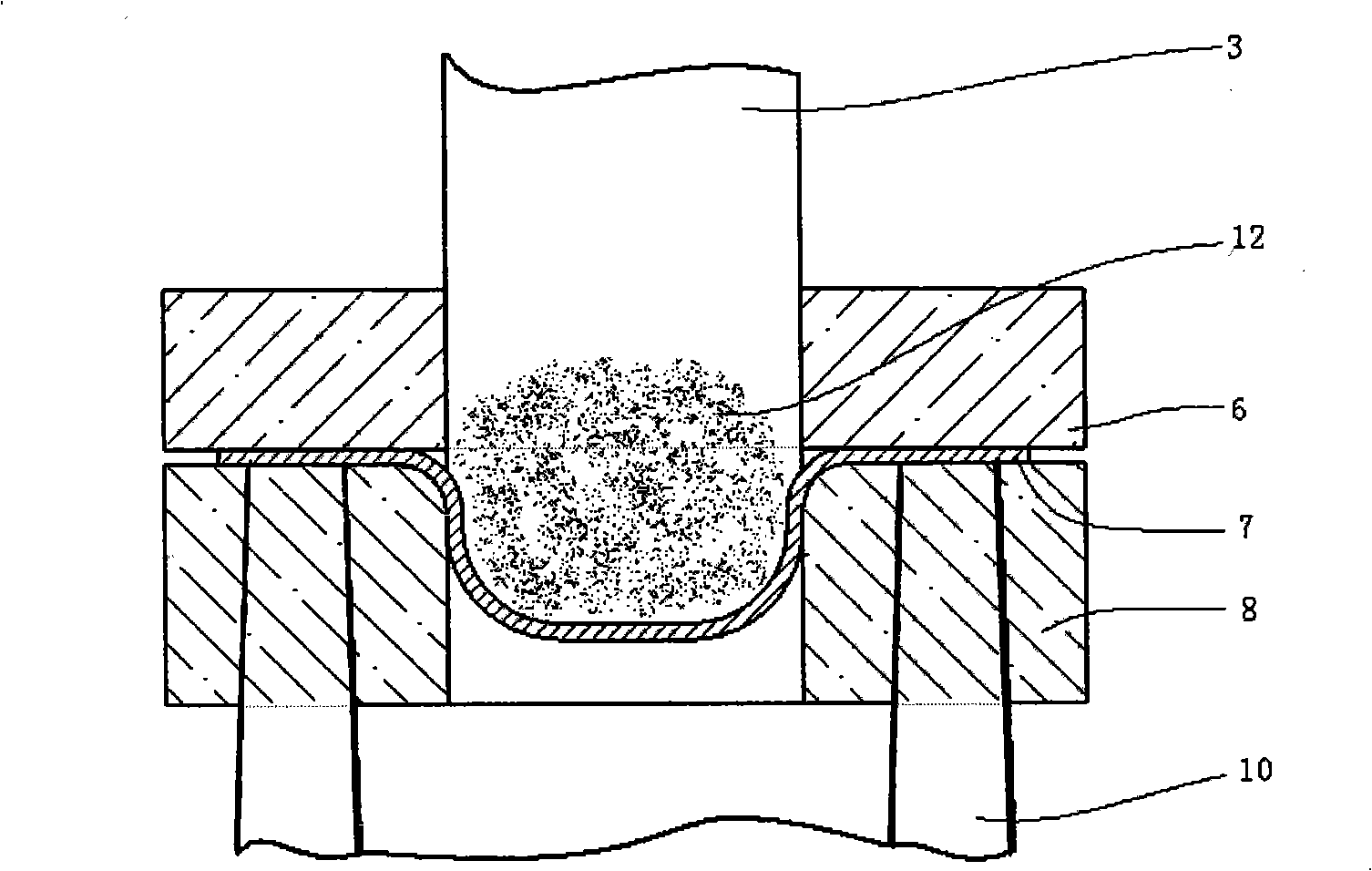

[0009] Pulse laser micro-drawing forming method with synchronous heating, the plate is clamped between the blank holder and the die, and placed on the three-coordinate workbench, the laser beam for heating from the laser generator B and the laser beam from the laser generator The impact laser beam of A irradiates the two surfaces of the plate respectively, so that the heating laser beam and the impact laser beam are coaxial; Center and reach the required spot size; the spot size of the impact laser beam is adjusted by the laser beam spatial modulator of laser generator A;

[0010] The annular laser beam emitted by laser generator B passes through the concave die to heat the edge area of the plate, which increases the plasticity of the material in this area, reduces the yield strength, and makes the material in the edge area prone to plastic flow; the columnar short beam emitted by laser generator A The pulsed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com