Method for preparing chlorinated polypropylene by heterogeneous mixed solvent method

A technology of chlorinated polypropylene and mixed solvents, which is applied in the field of industrialized production of chlorinated polypropylene, can solve the problems of reducing the reaction temperature and pressure of the solvent method, and achieve the effects of cost-environmental friendliness, low cost, and reduction of reaction temperature and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

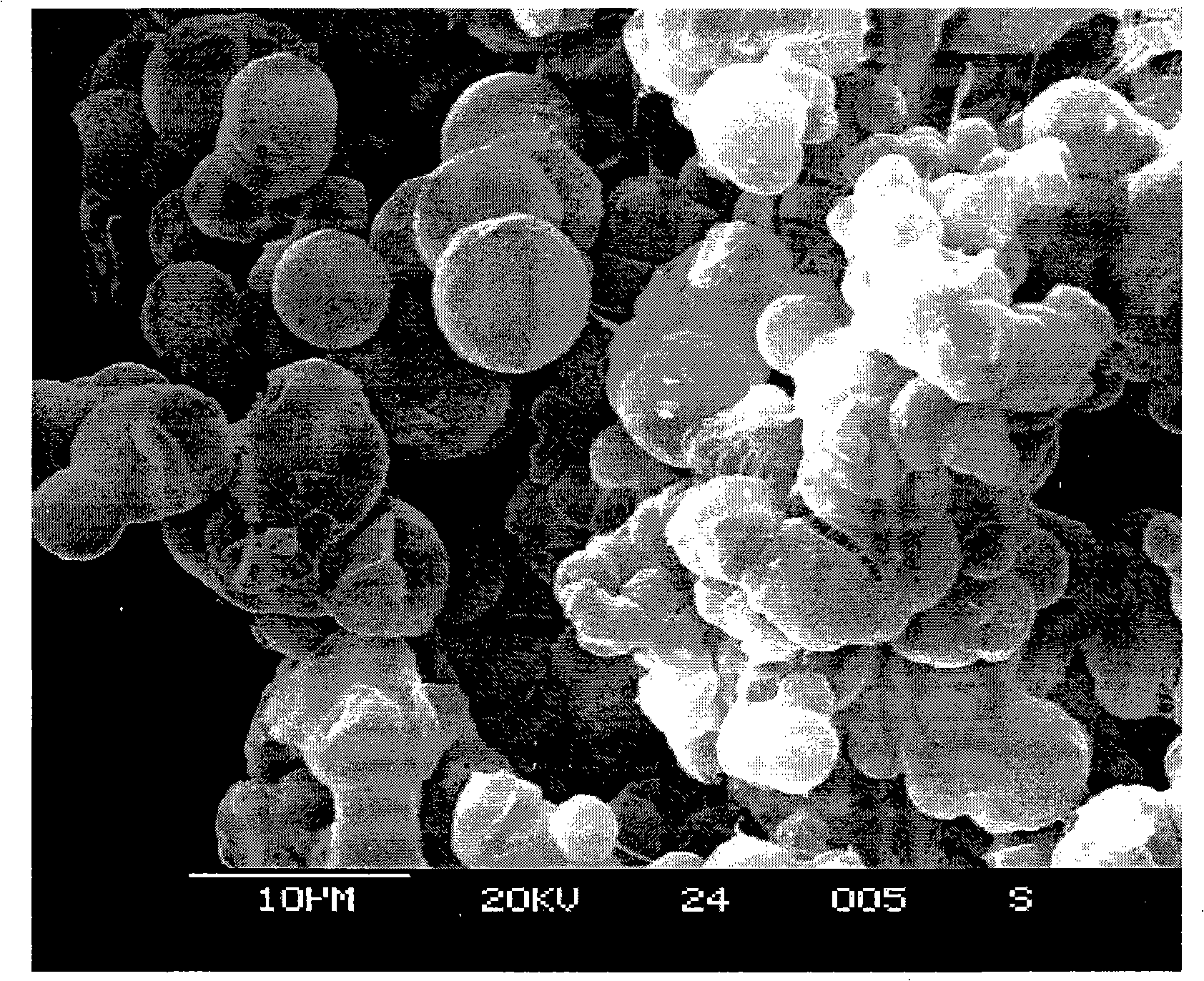

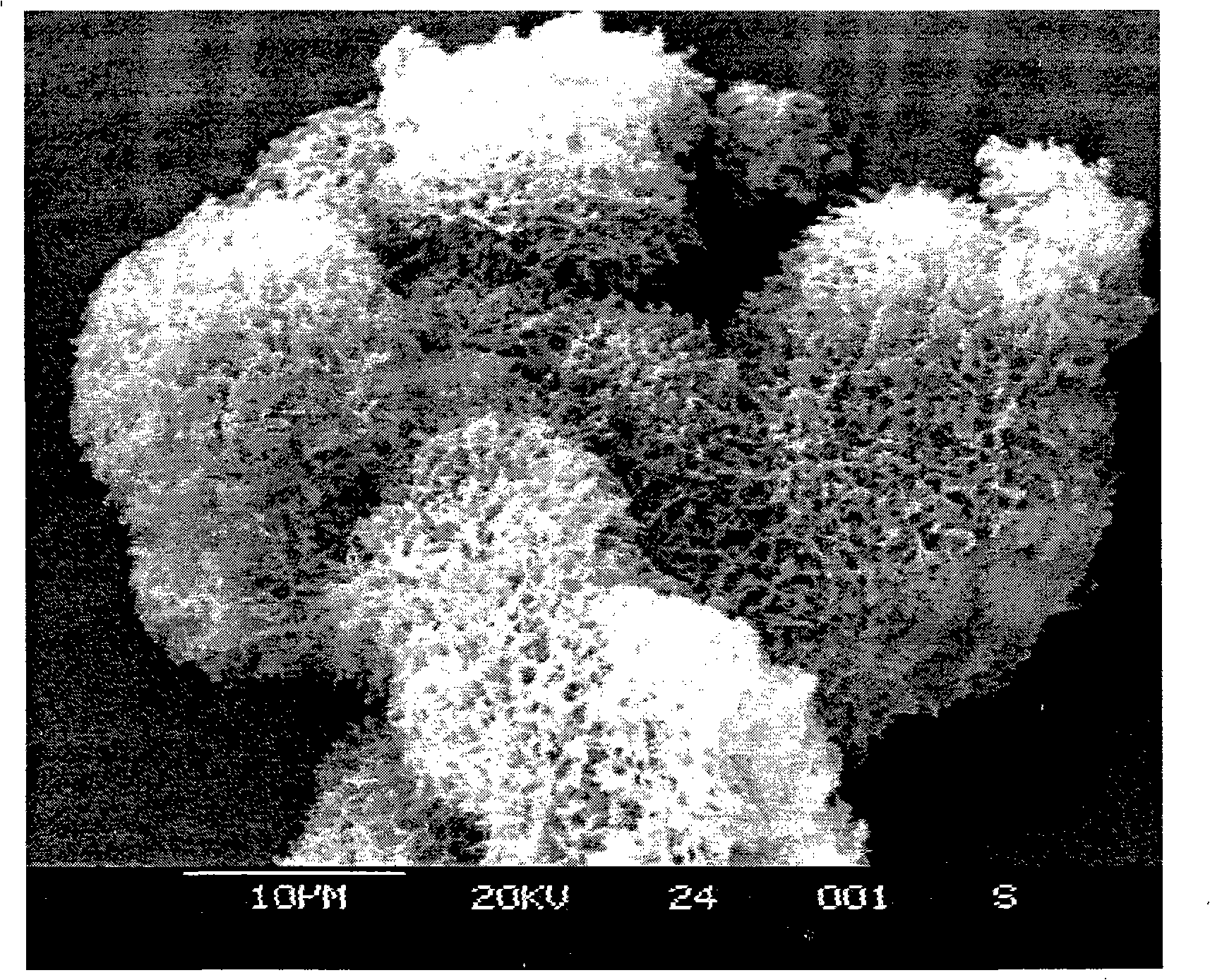

Image

Examples

Embodiment 1

[0023]Put 1200kg (800L) of chloroform, 24kg of isotactic polypropylene and 0.6kg of Span80 into the 2000L enamel reaction kettle A, then, in the stirring state, raise the temperature of the material in the kettle to 100°C, and keep it warm at this temperature for 1 hours to completely dissolve the polypropylene in chloroform. While reactor A was warming up and kept warm, 1200kg (800L) of chloroform and 0.6kg of Span80 were dropped into reactor B, and the room temperature was kept for use. After the material in the reactor A is kept warm, press the chloroform in the reactor B into the reactor A with compressed air. At this time, the temperature of the material in the reactor A will drop to between 50°C and 55°C. The form precipitated from chloroform. Maintain the temperature at 50° C., then put 0.12 kg of azobisisobutyronitrile and 5% 60 kg (60 L) of dilute hydrochloric acid into the reactor and stir for 15 minutes, then feed 16 kg of chlorine into the reactor. After the reac...

Embodiment 2

[0025] Put 960kg (640L) of chloroform and 140kg of isotactic polypropylene into a 2000L enamel reaction kettle A, then, in a stirring state, raise the temperature of the material in the kettle to 115°C, and keep it warm at this temperature for 3 hours to make the poly Propylene was completely dissolved in chloroform. While reactor A was warming up and kept warm, 960 g (640 L) of chloroform was dropped into reactor B, and the room temperature was kept for use. After the material in the reactor A is kept warm, press the chloroform in the reactor B into the reactor A with compressed air. At this time, the temperature of the material in the reactor A will drop to between 55°C and 60°C. The form precipitated from chloroform. Maintain the temperature at 55°C. Then put 0.7kg of azobisisobutyronitrile and 320kg (320L) of water into the reactor and stir for 15 minutes, then feed 156kg of chlorine gas into the reactor for reaction. After the reaction was finished, the unreacted chlori...

Embodiment 3

[0027] Put 1050kg (700L) of chloroform, 210kg of syndiotactic polypropylene and 10.5kg of Span80 into the 2000L enamel reaction kettle A, then, in the stirring state, raise the temperature of the material in the kettle to 130°C, and keep it warm at this temperature for 6 hours to completely dissolve the polypropylene in chloroform. While reactor A was warming up and kept warm, 840kg (560L) of chloroform and 8.4kg of Span80 were dropped into reactor B, and the room temperature was kept for use. After the material in the reactor A is kept warm, use compressed air to quickly press the chloroform in the reactor B into the reactor A. At this time, the temperature of the material in the reactor A will drop to between 65°C and 70°C. The form is precipitated from chloroform. Continue to reduce the temperature to 61.5°C, then add 0.63kg of benzoyl peroxide and 630kg (630L) of water into the reactor and stir for 25 minutes, then feed 420kg of chlorine into the reactor to react. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com