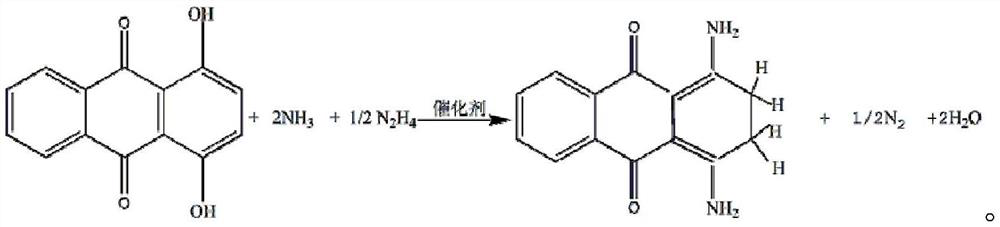

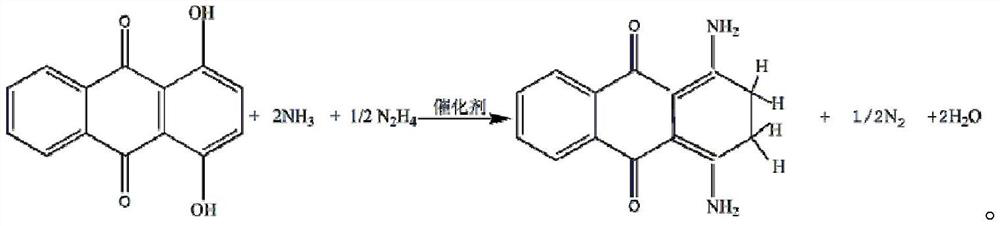

Clean process for synthesizing 1, 4-diamino-anthraquinone leuco body

A technology of diaminoanthraquinone and dihydroxyanthraquinone, which is applied in the clean process field of synthesizing 1,4-diaminoanthraquinone leuco, which can solve the problems of loss and high production cost, achieve process safety and reduce reaction temperature And pressure, shorten the effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1000ml stainless steel autoclave, drop into 1,4-dihydroxyanthraquinone 50.00 grams (0.208mol), industrial ammonia 600 grams (ammonia content 25%), hydrazine hydrate 10.00 grams (0.200mol), catalyst (TBAB) 0.50g, test After pressing, slowly raise the temperature for about 30 minutes at 60-65°C, with a positive pressure of 0.15-0.20Mpa, keep warm for 1 hour, and release the pressure to remove ammonia (ammonia enters the recycling and recovery system) at the end of the heat preservation. The material is filtered and washed until neutral, and dried to 1 , 49.84 grams of 4-diaminoanthraquinone leuco, the content detected by HPLC was 95.43%, and the reaction yield was 95.12%.

Embodiment 2

[0028] 1000ml stainless steel autoclave, put 50.00g of 1,4-dihydroxyanthraquinone, 500g of industrial ammonia water (25% ammonia content), 7.3g of hydrazine hydrate (0.146mol), 1.0g of catalyst (TBAB), and slowly heat up after pressure test About 60min at 65-70°C, positive pressure 0.15-0.20Mpa, heat preservation for 1h, pressure release and deamination at the end of heat preservation (ammonia enters the recycling system), the material is filtered and washed until neutral, and dried to obtain 1,4-di Aminoanthraquinone leuco is 49.69 g, the content detected by HPLC is 95.12%, and the reaction yield is 94.53%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com