Production device and preparation method for synthesizing aminopropyltriethoxysilane by low-temperature low-pressure method

A technology of aminopropyltriethoxysilane and cyanoethyltriethoxysilane, which is applied in the field of production equipment and preparation, can solve the problems of pollutant discharge impact, high reaction temperature and reaction pressure, and reduce equipment investment costs , reduce the reaction temperature and pressure, improve the effect of production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

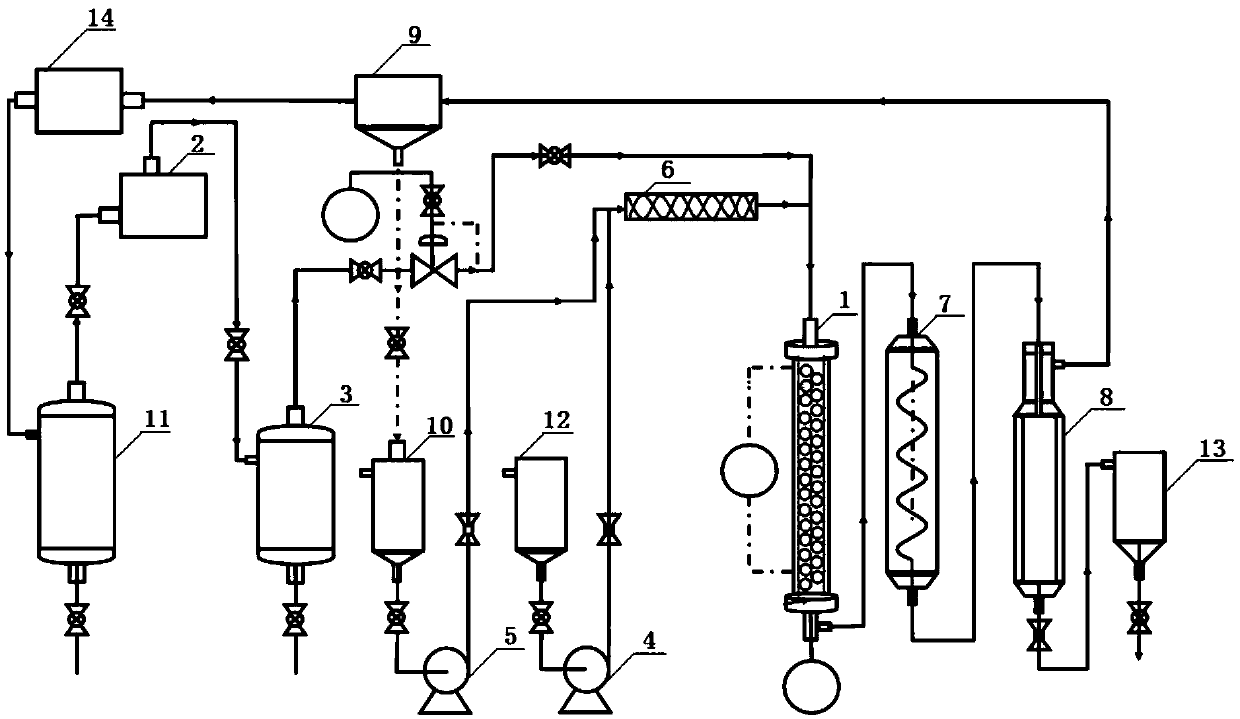

[0031] Specific embodiment 1: This embodiment low-temperature low-pressure synthesis of aminopropyl triethoxysilane production device, the device includes a tubular reactor 1, a first hydrogen circulation compressor 2, a second hydrogen circulation compressor 14, hydrogen buffer Tank 3, raw material flow pump 4, liquid ammonia flow pump 5, SK static mixer 6, cooler 7, gas-liquid separator 8, liquid ammonia cooler 9, liquid ammonia storage tank 10, hydrogen storage tank 11, cyanoethyl The triethoxysilane storage tank 12 and the product receiving storage tank 13 are characterized by:

[0032] The upper end of the hydrogen storage tank 11 is connected to the side end of the first hydrogen circulating compressor 2, the upper end of the first hydrogen circulating compressor 2 is connected to the side end of the hydrogen buffer tank 3, the upper end of the hydrogen buffer tank 3 and one end of the SK static mixer 6 are connected to the pipe The upper end of the tubular reactor 1 is con...

specific Embodiment approach 2

[0033] Specific embodiment two: this embodiment is different from specific embodiment one in that the preparation method of low temperature and low pressure synthesis of aminopropyltriethoxysilane is as follows:

[0034] 1. Pack the magnetically immobilized catalyst filler in the tubular reactor 1, and increase the temperature in the tubular reactor 1 to 90°C;

[0035] 2. Turn on the first hydrogen circulating compressor 2, pass the hydrogen in the hydrogen storage tank 11 into the tubular reactor 1 through the hydrogen buffer tank 3, control the hydrogen pressure to 1.0MPa, and pass the raw material flow pump 4 to the cyanoethyl group Triethoxysilane is pumped into the tubular reactor 1 at a flow rate of 0.1t / h~0.25t / h, and at the same time, liquid ammonia is pumped at a flow rate of 0.1t / h~0.25t / h through the liquid ammonia flow pump 5. Into the tubular reactor 1, cyanoethyltriethoxysilane and liquid ammonia are uniformly mixed in the SK static mixer 6 and then enter the tubular ...

specific Embodiment approach 3

[0037] Specific embodiment three: This embodiment is different from the specific embodiment two in that the preparation method of the magnetically immobilized catalyst is as follows:

[0038] 1. Put 65 parts by mass of metallic nickel, 23 parts by mass of aluminum and 12 parts by mass of accelerator into a high-temperature furnace to obtain a uniformly mixed melt. The melt is quenched and quenched to obtain a quenched alloy, which is then crushed to a diameter of 0.1~0.5cm particles;

[0039] 2. The particles obtained in step 1 are leached from the alloy with sodium hydroxide solution with a mass concentration of 25% at 50°C, and the entire leaching process lasts 20-40 minutes;

[0040] 3. Wash the leached alloy treated in step 2 with ultrapure water, and at the same time pass hydrogen to activate the alloy, and then rinse with ethanol to obtain a modified catalyst;

[0041] 4. Using neodymium-iron-boron with rare earth dysprosium as the strong magnetic center, the modified catalyst i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com