Polychloroethylene production reaction temperature control method for small-sized polymerization kettle DCS

A technology of reaction temperature and polyvinyl chloride, which is applied in the direction of temperature control using electric methods, can solve problems affecting product quality, unstable reaction, and difficulty in reaching the reaction state, so as to improve detection accuracy and control accuracy and reduce accidents. efficiency and optimize product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

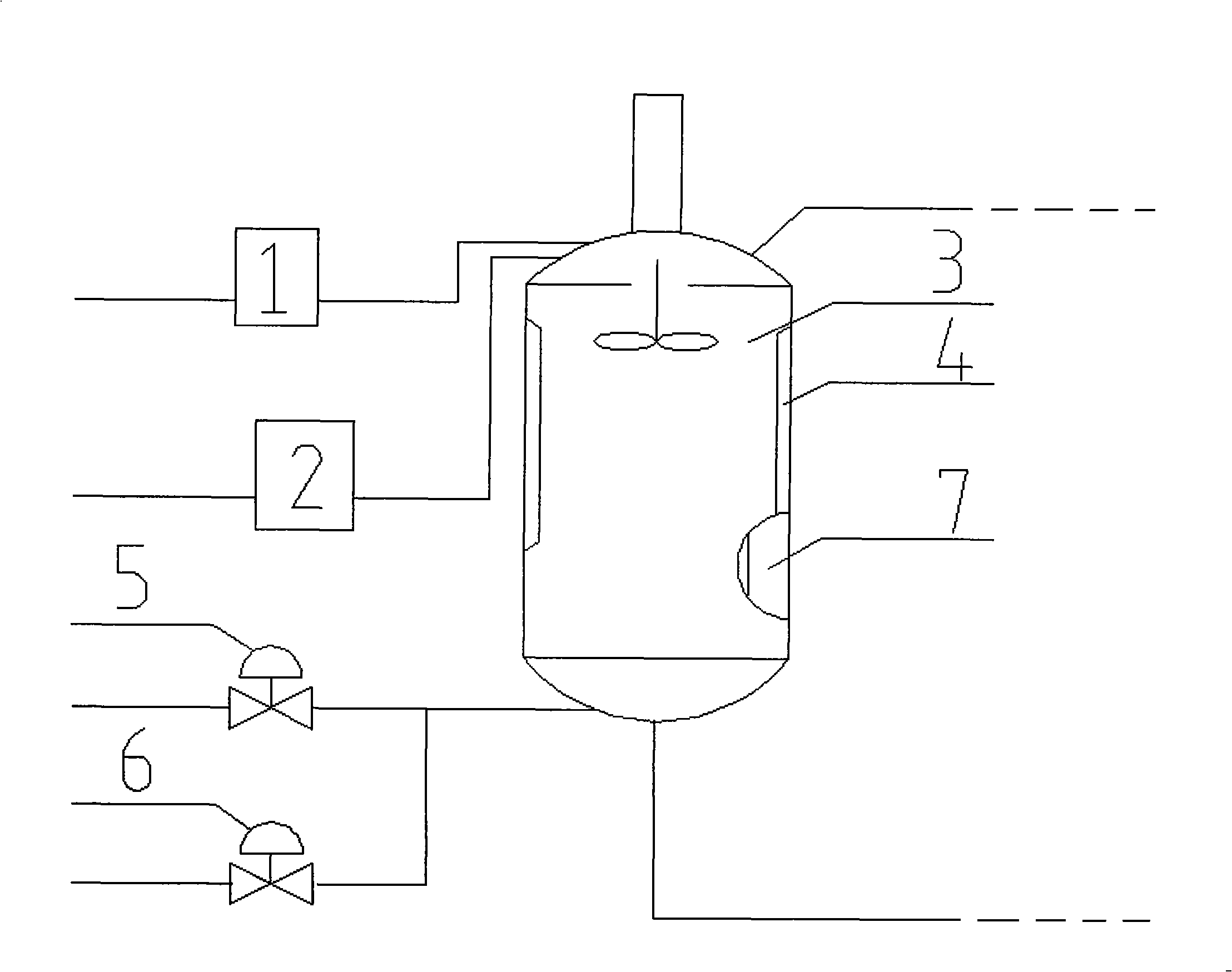

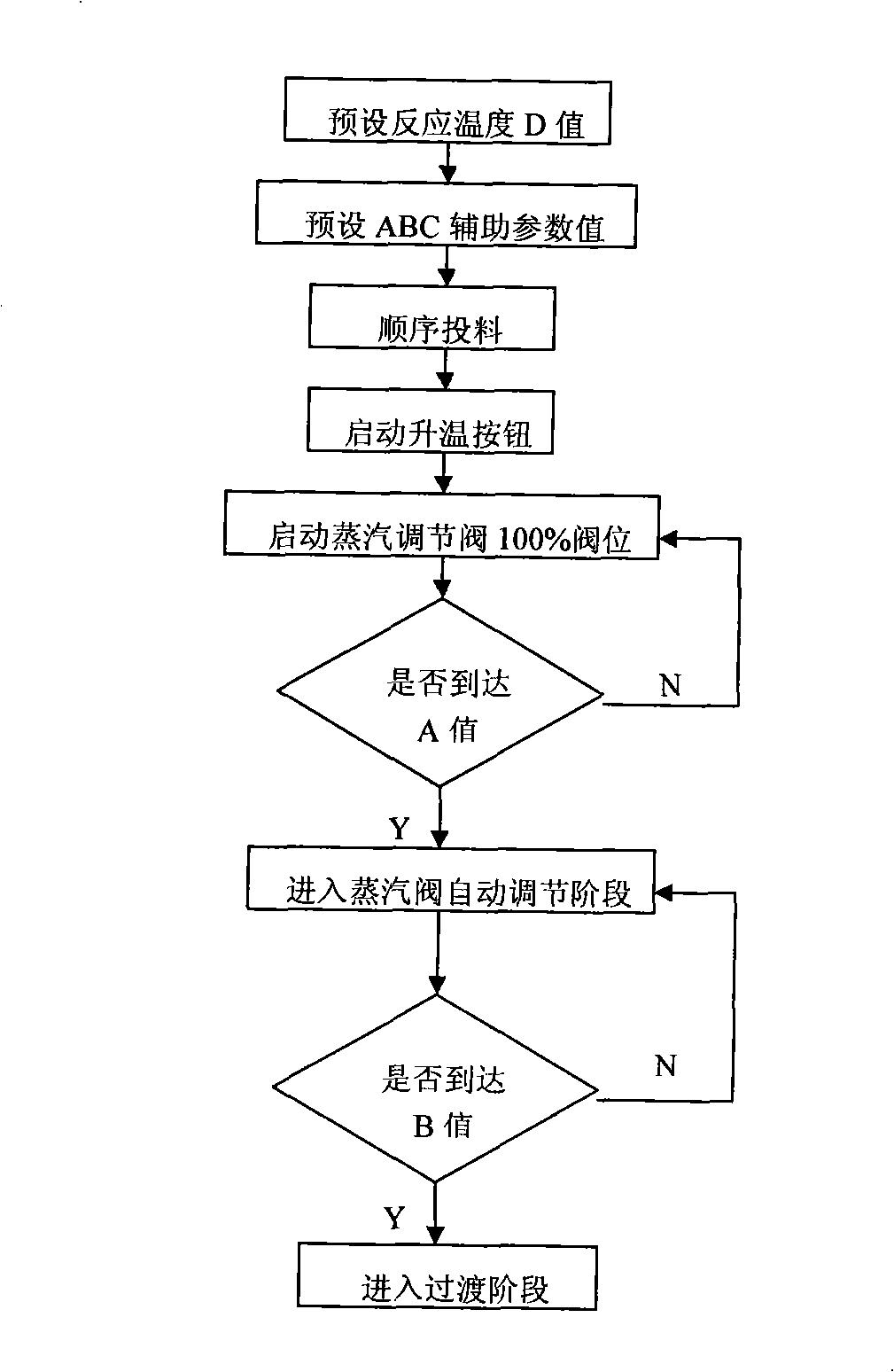

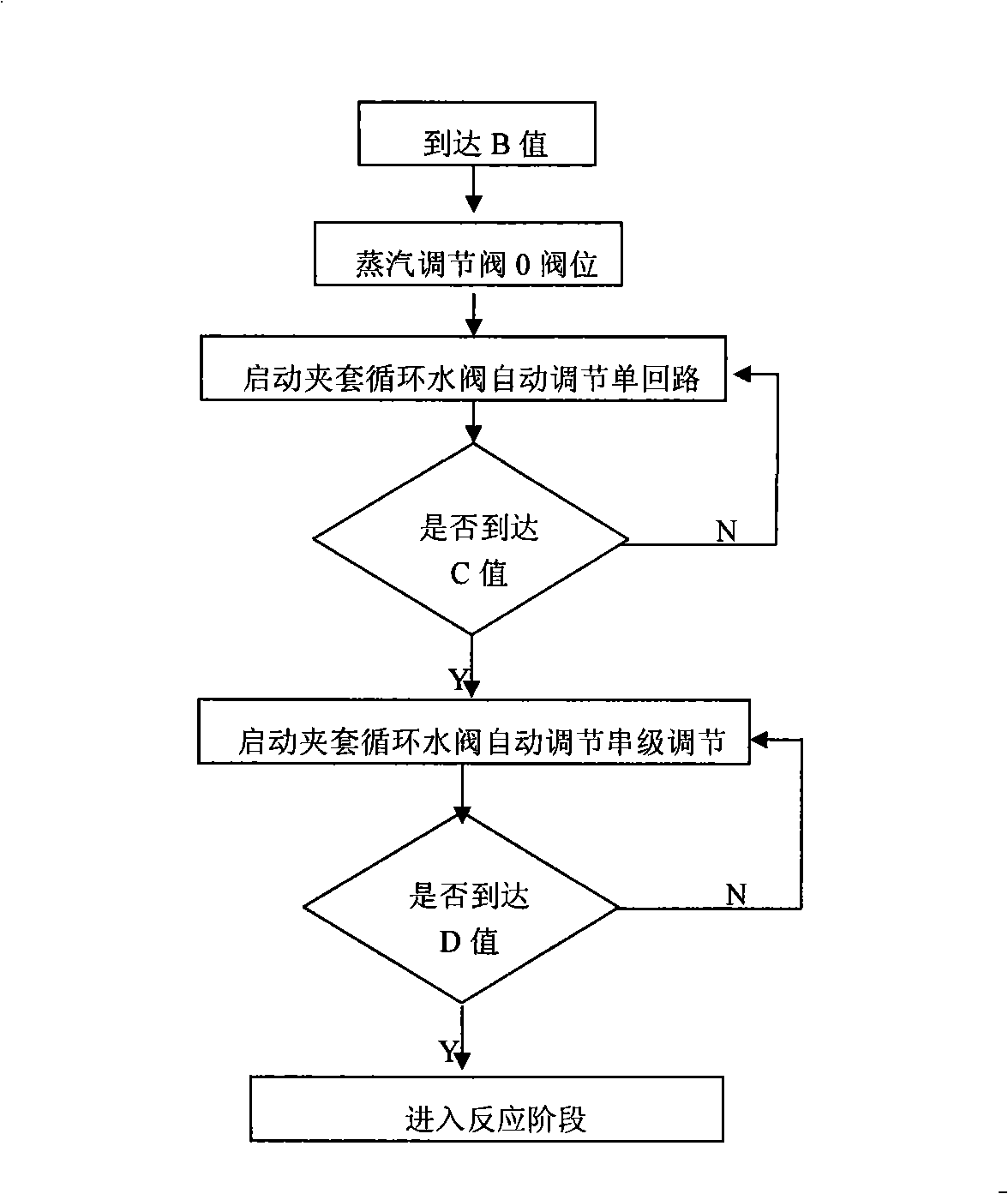

Method used

Image

Examples

Embodiment 2

[0018] The difference between Example 2 and Example 1 is that the preset constant temperature reaction temperature D value is 65, and then preset the three values of A, B, and C as 61.8, 62, and 63.5, and then partially open the steam regulating valve after sequential feeding .

Embodiment 3

[0019] The difference between Example 3 and Example 1 is: the preset constant temperature reaction temperature D value is 58.5, and then preset at least three values of A, B, and C to be 53, 54, and 55.5, and then fully open the steam adjustment after sequential feeding valve.

Embodiment 4

[0020] The difference between Example 4 and Example 1 is that the preset reaction temperature D value is 60, and the preset five values of A, B, C, E, and F are 54, 55, 56.5, 57, 58.5 after sequential feeding Then partially open the steam regulating valve.

[0021] The preset temperature reference values in the above embodiments can be multiple based on experience, and the specific value has a very important relationship with the size of the reactor and the reaction characteristics.

[0022] The present invention mainly improves the control of heating up and transition stages, and the others are the same as the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com