Fine phthalocyanine pigment particle and process for producing the same, photoresist containing dispersed pigment, colored transfer material, color filter, and liquid-crystal display

A manufacturing method and technology of phthalocyanines, which are applied in the field of color filters and liquid crystal display devices, and the manufacture of phthalocyanine pigment particles, which can solve the problems of inability to use pipelines, high viscosity of pigment dispersions, and lack of supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0135] In the preparation conditions of the organic pigment solution, the preparation conditions of the organic pigment solution are not particularly limited, and the range from normal pressure to subcritical and supercritical conditions can be selected. For organic pigments, from the viewpoint of improving the yield, it is preferred to dissolve under pressure, preferably at 10 5 ~10 8 The dissolution was carried out under the pressure of Pa. When the dissolution is performed under normal pressure, the temperature is preferably -10°C to 150°C, more preferably -5°C to 130°C, particularly preferably 0°C to 100°C.

[0136] When producing the pigment dispersion composition of the present invention, the organic pigment contained in the organic pigment solution used must be uniformly dissolved in a good solvent, but it is also preferable to dissolve it under acidic or alkaline conditions. Generally, alkaline conditions are used when using pigments that have groups that can be diss...

Embodiment 1

[0453] Pigment solution A was prepared by adding 3.3 mL of 28% sodium methoxide methanol solution, 6000 mg of pigment (Pigment Green 36), 6000 mg of polyvinylpyrrolidone, and 600 mg of pigment dispersant A to 100 mL of dimethyl sulfoxide.

[0454] Separately, 1000 mL of water containing 4.3 mL of 1 mol / L hydrochloric acid was prepared as a poor solvent.

[0455] Pigment dispersant A was prepared according to the method disclosed in JP-A-2000-239554.

[0456] Pigment dispersant A

[0457]

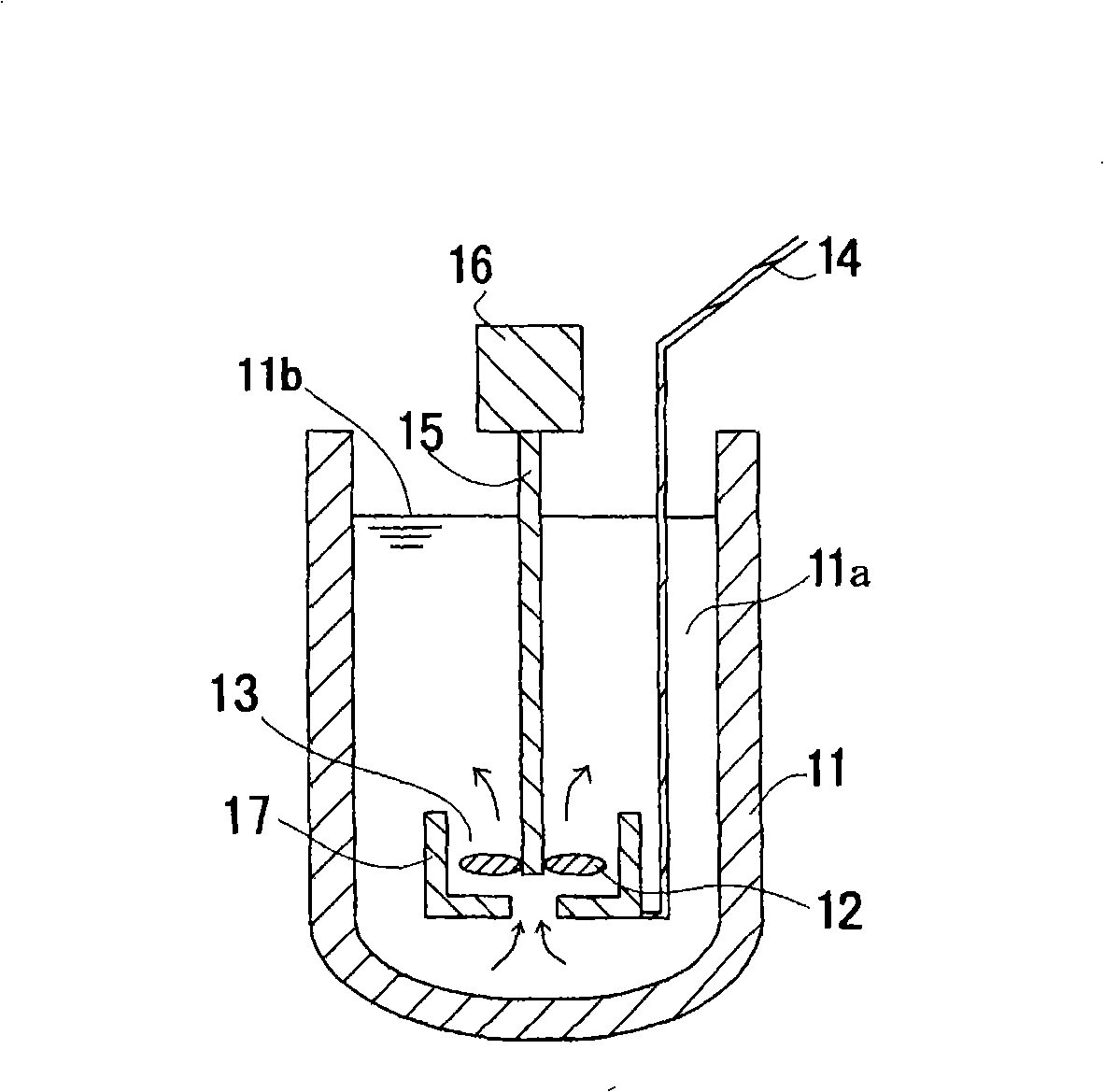

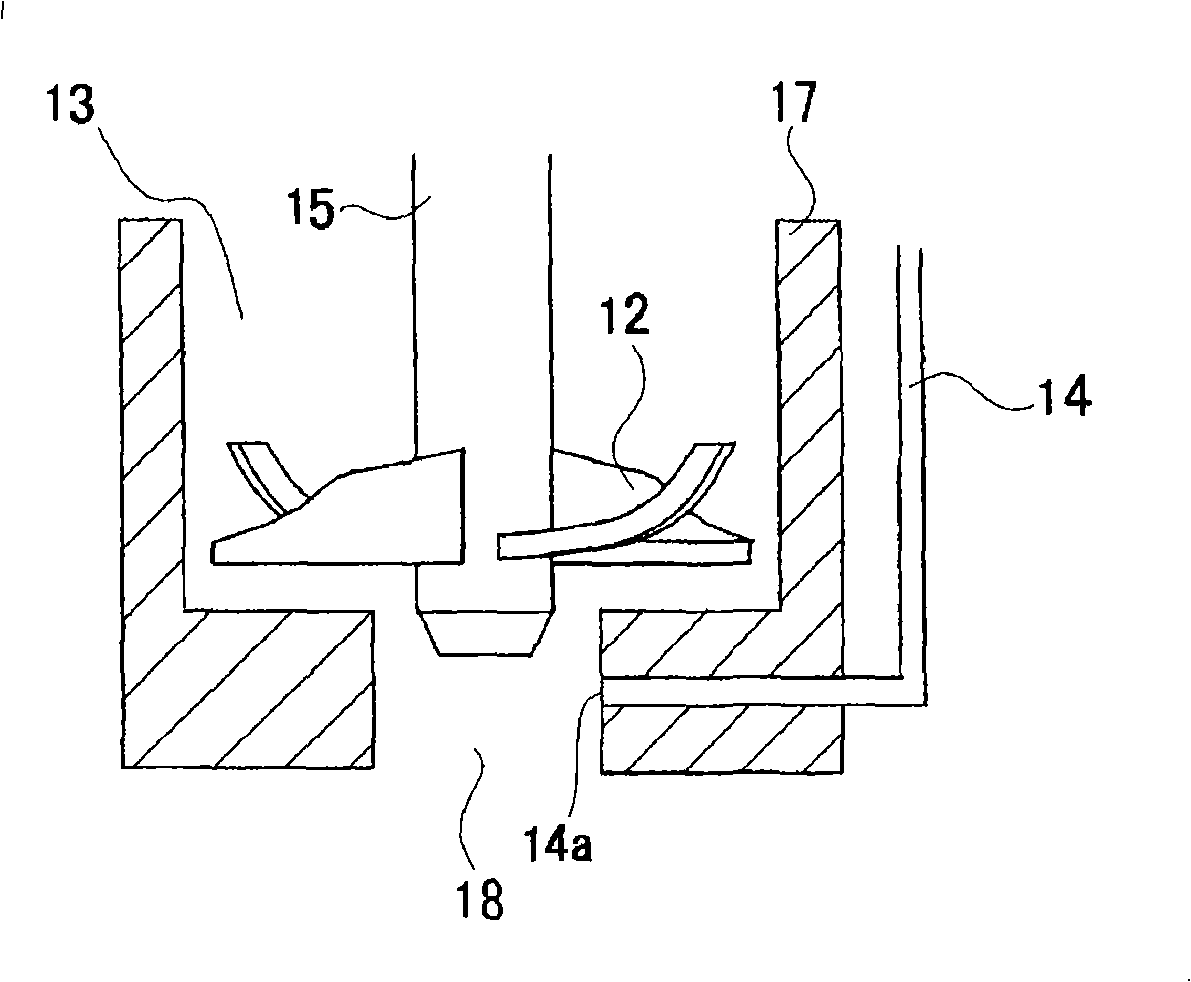

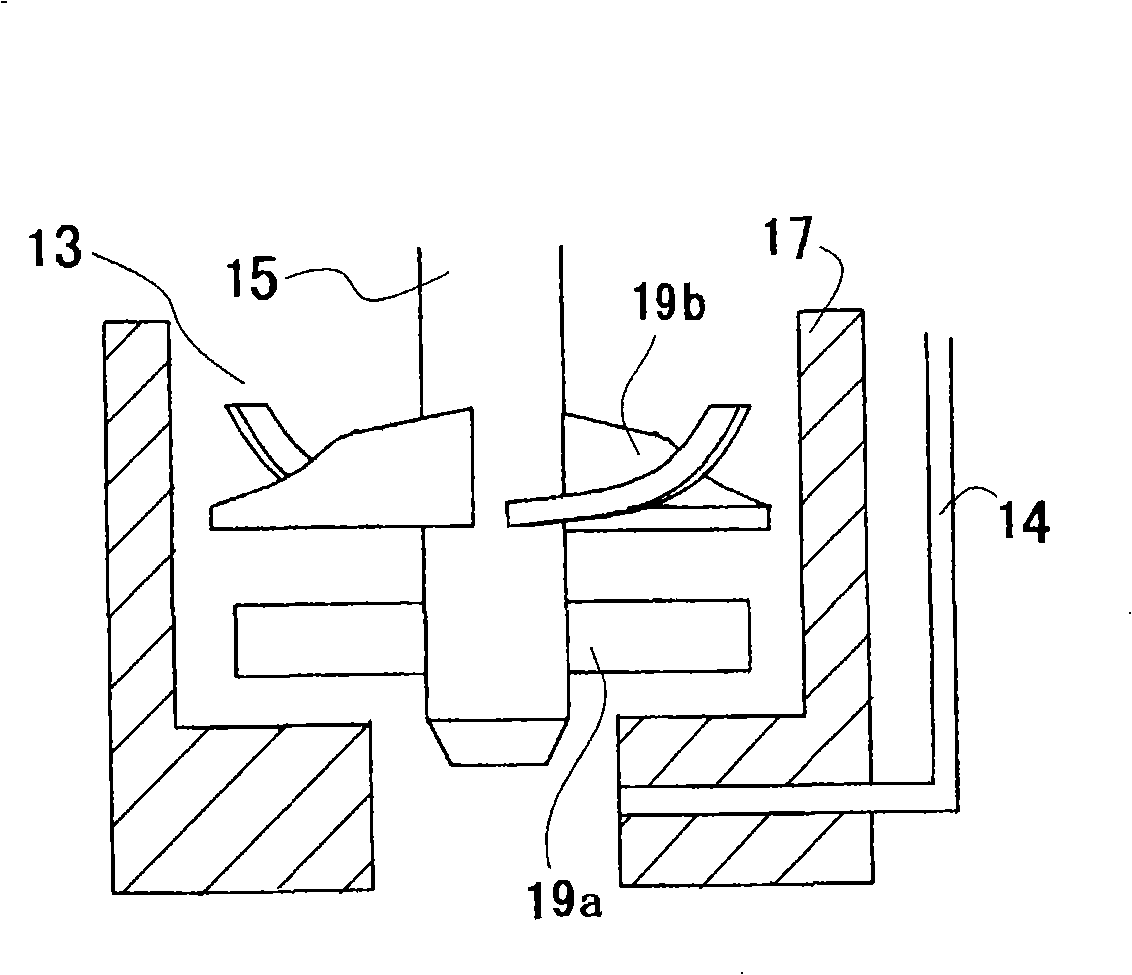

[0458] At this time, the temperature was controlled at 1° C., and the GK-0222-10 Ramond star manufactured by Fujisawa Pharmaceutical Co., Ltd. was used in 1000 mL of water, a poor solvent stirred at a rotation speed of 500 rpm. The NP-KX-500 large-capacity non-pulsation pump injected 200mL of pigment solution A at a flow rate of 50mL / min to form nano-pigment particles, thereby preparing pigment dispersion A. The particle diameter and degree of monodispersity of the pigment dispersion li...

Embodiment 2

[0469] A pigment solution B was prepared in the same manner as in Example 1, and a pigment dispersion liquid B was further prepared, except that the pigment dispersant B used in Example 1 was replaced with the following pigment dispersant B. The particle diameter and monodispersity were measured, and the measured number average particle diameter was 34 nm, and Mv / Mn was 1.30. A paste-like concentrated pigment solution B (concentration of nanopigment: 35% by mass) was prepared in the same manner as in Example 1, and a pigment dispersion composition B was further prepared.

[0470] Pigment dispersant B is the following compound prepared according to the preparation method of pigment dispersant c in JP-A-5-72943.

[0471] Pigment dispersant B

[0472]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com