High anti-corrosive anti-corrosive primer for interpenetration network material and method for preparing same

An anti-corrosion, anti-rust, interpenetrating network technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of unsatisfactory anti-corrosion and anti-rust performance, no interpenetrating network, no product launch, etc., achieving considerable social and economic benefits, three The effect of good anti-performance and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

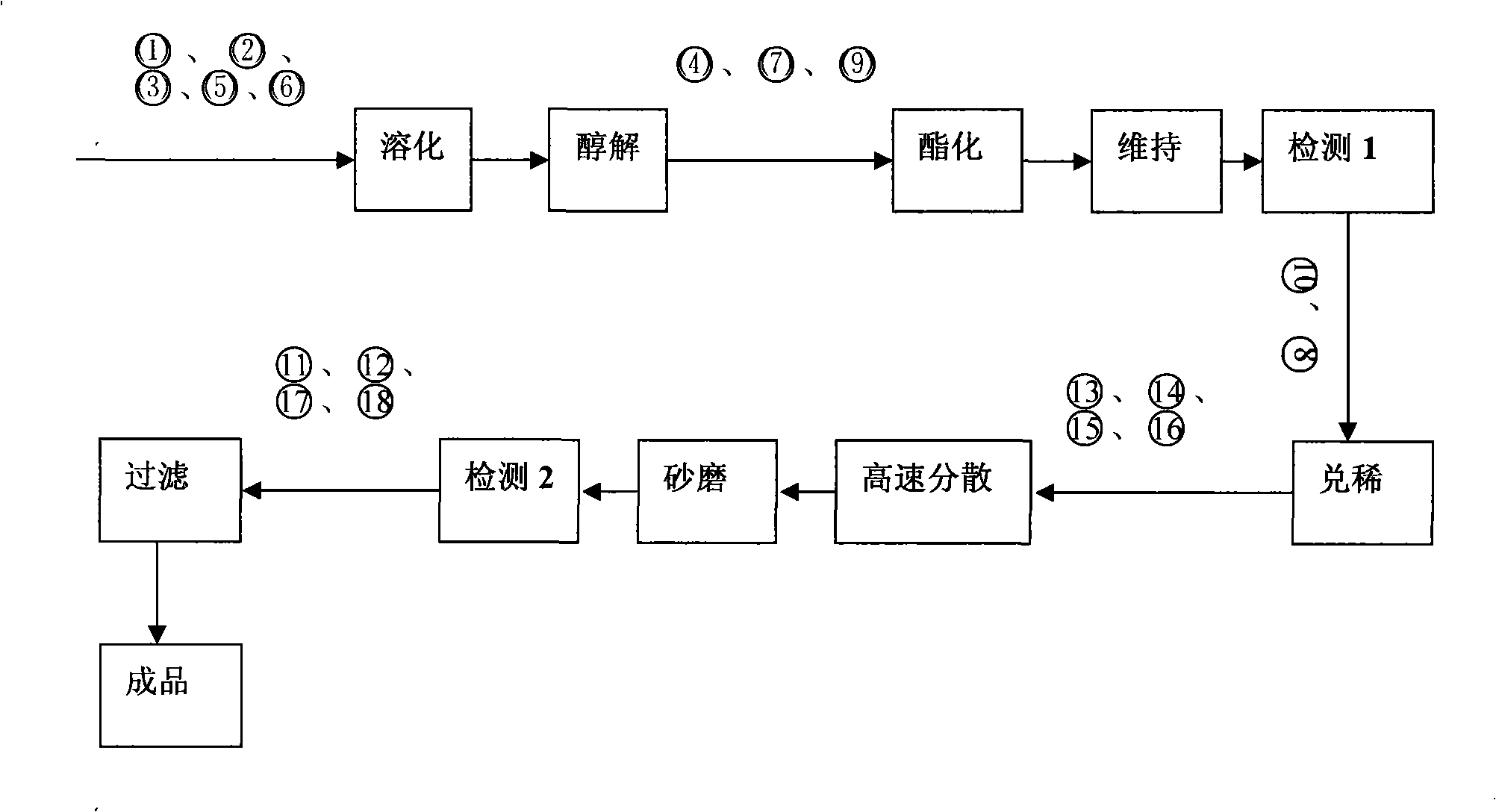

[0010] The technical content of the present invention will now be described in detail in conjunction with the accompanying drawings.

[0011] 1. the raw material and percentage by weight thereof that the present invention selects are:

[0012] ① First grade tung oil: 3.8%-4.2%;

[0013] ②First grade rosin: 3.8%-4.2%;

[0014] ③424 # Resin: 4.2%-4.8%;

[0015] ④Refined castor oil: 3.8%-4.2%;

[0016] ⑤ Trimethylolpropane (TMP): 1.5%-1.7%;

[0017] ⑥Polyester chips: 5.5%-6.1%;

[0018] ⑦Glycerin: 0.8%;

[0019] ⑧Xylene: 12.3%-13.7%;

[0020] ⑨Huang Dan: 0.1%;

[0021] ⑩601 epoxy resin: 2.8%-3.2%;

[0022] Cellulose (made in the United States): 7.6%-8.4%;

[0023] Butyl acetate: 28%-32%;

[0024] Pigments of various colors (optional): 5%-10%;

[0025] Aluminum tripolyphosphate: 6.6%-7.4%;

[0026] Green silicon carbide: 6.6%-7.4%;

[0027] Anti-settling agent (881B): 0.5%;

[0028] Defoamer (BYK141): 0.1%;

[0029] Leveling agent (BYK306): 0.1%.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com