High titan type low FeO content sinter and method for preparing same

A high-titanium, sintered ore technology, applied in the field of iron ore agglomeration, can solve the problems of greatly affecting equipment life, poor FeO content, and affecting environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The sinter preparation method includes the following steps: A, batching, B, mixing, C, cloth, D, ignition, sintering, E, thermal crushing, F, thermal screening, G, cooling, H, screening, and immediately after screening Can be smelted in a blast furnace. Specifically, the mixing in step B can be mixed twice; the sieving in step H can be sintered screening and sub-ditch screening.

[0026] Among them, after mixing, the moisture content of the mixture is controlled to be 7.20±0.20%, which has proved to be the most suitable moisture for granulating vanadium-titanium magnetite concentrate. The mixed moisture of vanadium-titanium magnetite concentrate is too high or too low, which is not conducive to granulation. Excessive moisture formation will form an over-wet layer and worsen sintering, and too low moisture will affect the granulation effect.

[0027] Among them, the height of the material layer is 500-680mm when cloth. In this range, the thick material layer cloth can prolon...

Embodiment 1

[0032] The examples used the following sintering raw materials with the following proportions: vanadium-titanium magnetite concentrate 55%, Australian fines 10%, domestic high-grade fines 12%, domestic medium-grade fines 3%, limestone 6%, quicklime 7%, and additional 35% return to mine. The fuel is coke powder or anthracite, the coke powder ratio is 3-7% or the anthracite ratio is 4-8% (corresponding to the mixture carbon content is 2.2-3.8%), 9 batches of sintered ore with different FeO content were prepared, The technical effects and related smelting performance indexes are shown in Table 2. In addition, the main phases and contents of some batches of sinters with different FeO content were tested. The results are shown in Table 3.

[0033] 1. Technical effect

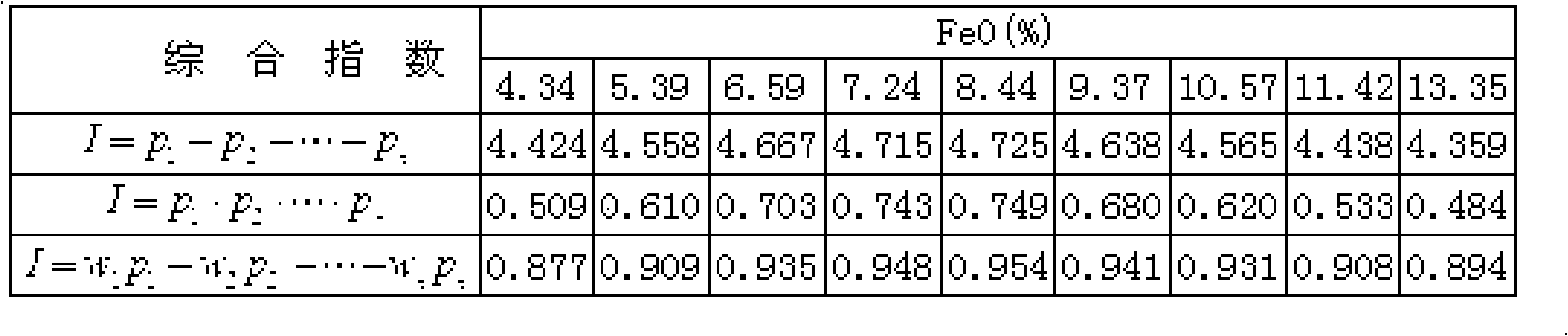

[0034] Table 2 The effect of different FeO content on the quality and energy consumption of sintered ore

[0035] Batch

number

With carbon

%

Sinter

FeO

%

Sintering speed

Degree

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com