Method for preparing high strength cemented carbide

A cemented carbide, high-strength technology, applied in the field of cemented carbide, can solve the problems of difficult recycling, easy volatility, and high procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

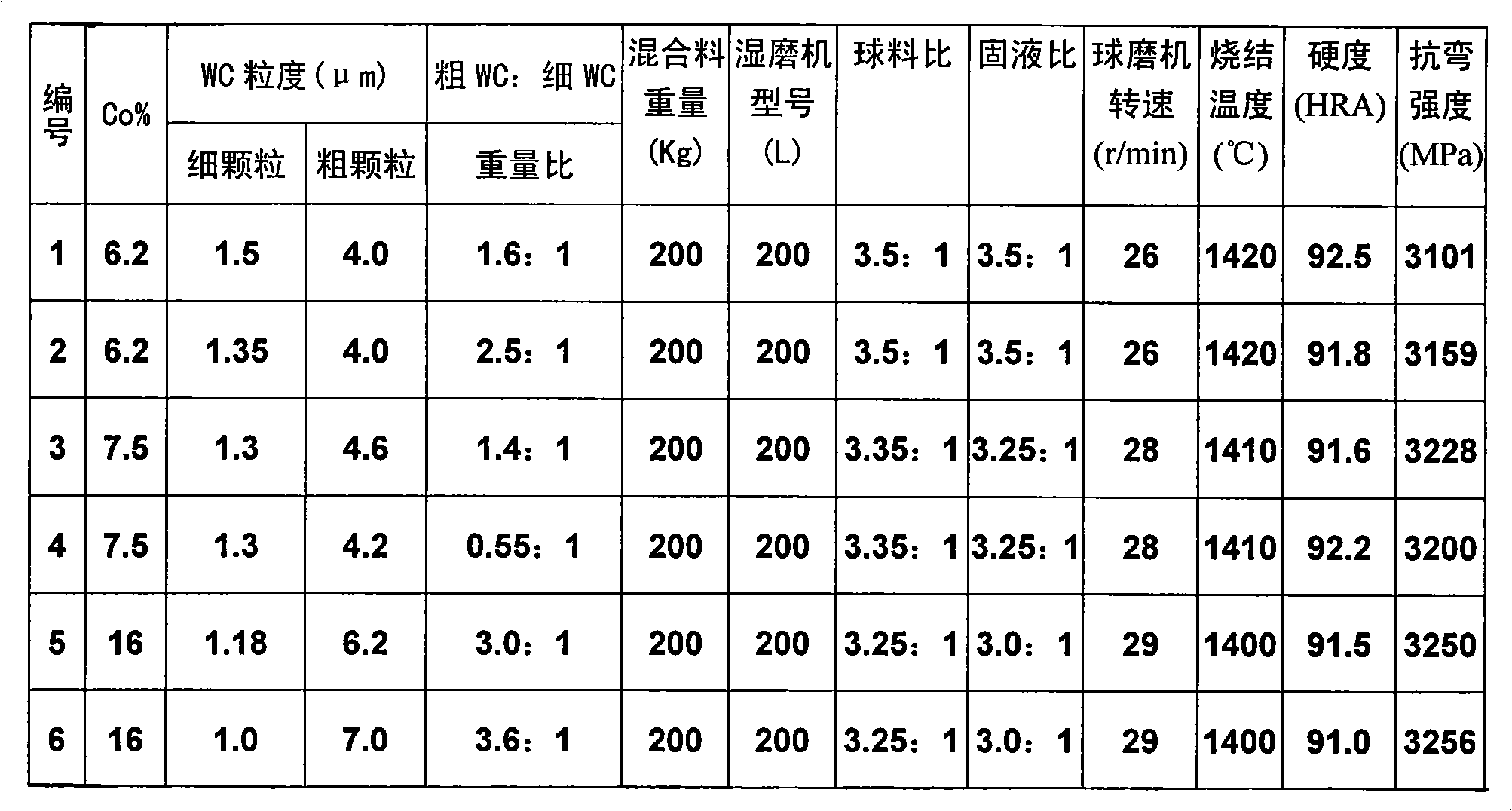

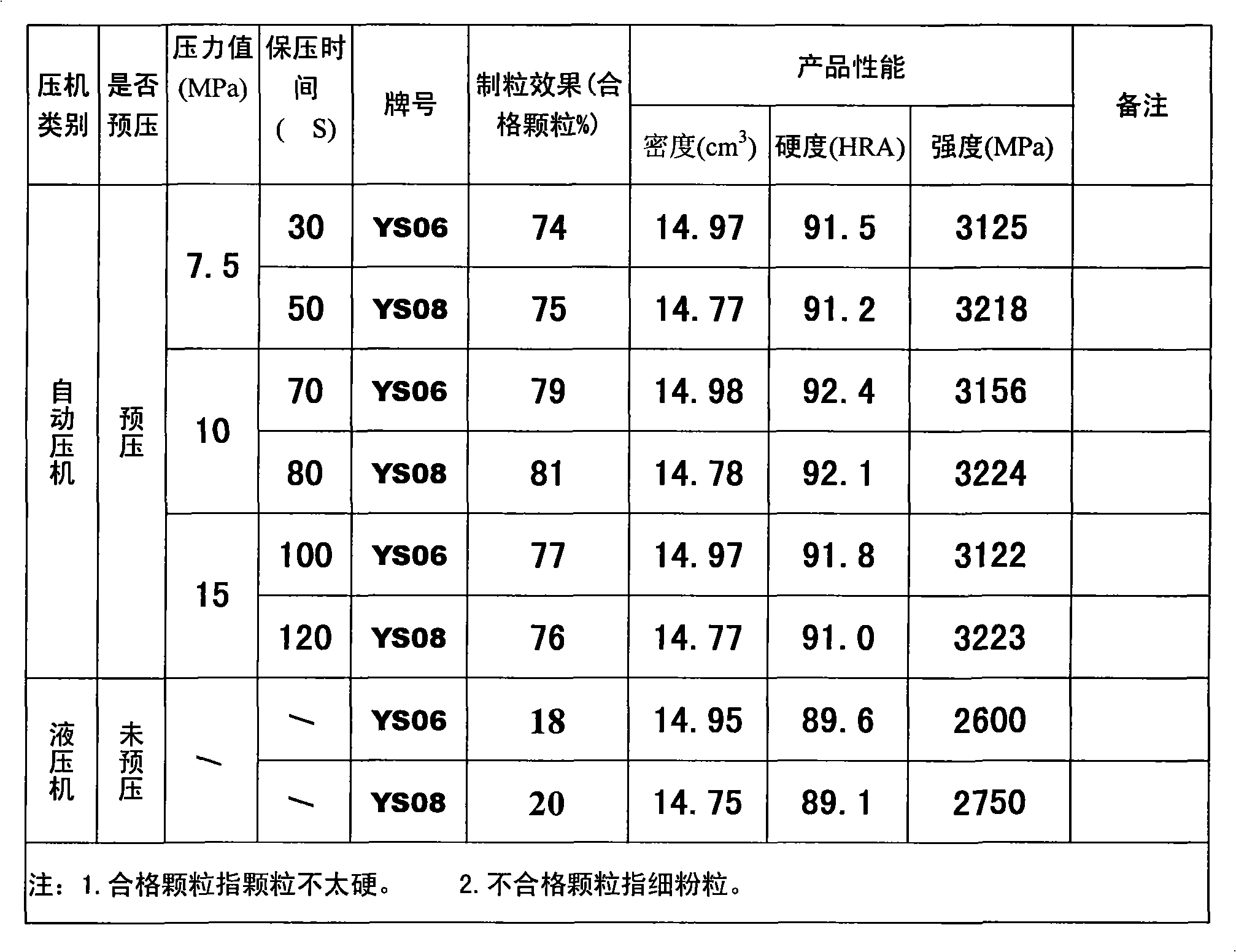

[0012] A preparation method of high-strength cemented carbide, including batching, wet grinding, adding molding agent and then wet grinding, drying, crushing, pre-pressing, passing through a 40-mesh sieve, granulating, compression molding, sintering dewaxing, passivation and other processes Step: When batching, the weight content of metal cobalt powder in the raw material components is 6-16%, and the rest is tungsten carbide with two different particle sizes. 7μm, the average particle size of fine tungsten carbide is 1-1.5μm; the weight content of tungsten carbide with two different particle sizes is: the ratio of coarse and fine tungsten carbide is 0.55-3.6:1; when wet grinding, the ball-to-material ratio is 3.25-3.5: 1. Add acetone as the grinding medium according to the solid-to-liquid ratio of 3-3.5:1, the grinding time is 20-28 hours, the speed of the ball mill is 25-29r / min; when wet grinding, add liquid paraffin at 60-80°C as a molding agent, and Liquid paraffin with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com